Pontiac’s legendary Ram-Air V program was perhaps the most celebrated engine that almost was. From its inception in the late ’60s, the engine was seen by both engineers and fans as the design that could have put Pontiac back on the top of the musclecar performance heap. With the 426 Hemi, 440 Six-Pak, Boss 429 Ford, and 427-454 Chevys providing serious competition to the top-dog 400 Ram-Air IV, engineers knew that something had to be done.

Taking a page from the FE Ford 427 Tunnel Port engine design, Pontiac en-–gineers adapted the general intake-port design and coupled it with the existing Ram-Air IV exhaust port and a new wedge-type combustion chamber. Dimensionally, the Ford and Pontiac V-8s were quite similar, so the adaptation was not too difficult for Pontiac engineers.

The 476ci Ram-Air V Pontiac features off-the-shelf short-block components combined with the new McCarty Racing reproduction Ram-Air V cylinder heads and street tunnel ram intake. Though this engine features a roller cam and 11.27:1 compression, it’s actually docile enough for street use.

The 476ci Ram-Air V Pontiac features off-the-shelf short-block components combined with the new McCarty Racing reproduction Ram-Air V cylinder heads and street tunnel ram intake. Though this engine features a roller cam and 11.27:1 compression, it’s actually docile enough for street use.

The first thing one notices when inspecting a Ram-Air V head is the size and shape of the intake ports. In a word, they are huge. Port volumes are in the 350cc range and their oval shape is so large that the pushrods go right through the centers of the intake ports—there is nowhere else for them to go. This shoehorning of the ports requires a revised valve placement. Instead of the familiar EIIEEIIE design, engineers used an EIEIIEIE pattern, which spaces both intake and exhaust valves equally—no more paired intake ports and siamesed exhaust ports here. While it didn’t change the firing order, it did necessitate the use of a specific camshaft with a corresponding lobe placement.

The intention was to build a total of four different versions of the Ram-Air V, including a 303ci short-deck version for SCCA Trans Am, a 366ci version for NASCAR, a 400 for street use, and a 428 for drag racing. With horsepower estimated at approximately 475 for the 400 and about 525 for the 428 versions, the Ram-Air V would have literally rewritten musclecar history, if of course, buyers didn’t mind a cold intake manifold, a complete loss of bottom end torque, and single-digit gas mileage. The truth was, the ports were too large for street use in anything smaller than about 480 ci.

1 Inside the dyno room, BES’ Rich Kolb gets ready for the baseline pull. Stacy McCarty (standing) and Lynn McCarty (seated) are hoping for the magical 750-plus-horsepower pull. Mopar Max Wedge Super Stock racer Ron Stewart (seen seated behind Rich) is a friend of the McCartys.

1 Inside the dyno room, BES’ Rich Kolb gets ready for the baseline pull. Stacy McCarty (standing) and Lynn McCarty (seated) are hoping for the magical 750-plus-horsepower pull. Mopar Max Wedge Super Stock racer Ron Stewart (seen seated behind Rich) is a friend of the McCartys.

In fact, a variety of factors killed it off, including the ’70 Clean Air Act and rapidly rising insurance rates. And with the departure of General Manager John Z. DeLorean, the engine no longer had a champion in upper management. The complete engines that were built—as well as the various parts, such as heads, intakes, camshafts, and other items—were sent into the parts network. It’s estimated that somewhere between 80 to 200 complete engines were built, as well as an unknown number of heads and intakes.

As one would imagine, the supply of Ram-Air V hardware quickly dried up, driving up prices to a near stratospheric level. As it stands right now, there aren’t enough loose original parts in existence to make up more than perhaps 8-10 Ram-Air V-headed engines. This is not even counting the use of ultra-rare Ram-Air V-specific blocks, distributors, harmonic balancers, or exhaust manifolds.

2 A previous dyno session revealed that the engine was hampered by a lean condition, so the baseline pulls for this session were made with #82 jets all around.

2 A previous dyno session revealed that the engine was hampered by a lean condition, so the baseline pulls for this session were made with #82 jets all around.

Today, though, unobtanium is now readily available. Thanks to the efforts of veteran NHRA racer Lynn McCarty, the Ram-Air V’s tunnel-ported heart is once again beating. He has spent the last five years developing a reproduction aluminum Ram-Air V cylinder head, as well as two different intake manifolds. These new parts are not only a financially viable option for a Pontiac-engine builder looking for something different, they also feature 21st-century design enhancements.

“I’ve been a fan of the Ram-Air Vs since the early ’80s,” McCarty recalled. “My brother Stacy and I built a ’69 Trans Am clone for A/MP with a 440ci tunnel-port Ram-Air V that clocked 9.40s at 146 mph in the quarter at 3,450 pounds and shifted at 9,000-plus rpm.”

Updated Design

The original Ram-Air V heads did flow a lot of air, even more than the legendary 426 Hemi, but unfortunately, intake port flow is not the only factor when making power. Though they flowed like the Mississippi on a test rig, they were hampered by very low velocity, especially when fitted on anything smaller than a 428. Some additional development by Pontiac would have no doubt improved the situation, but the project was cancelled before those changes could be made.

6 After dyno testing, we did a partial teardown to reveal the internal engine parts. McCarty Racing’s available dual-quad street tunnel ram is an extremely well-thought-out unit, with a large plenum, straight runners, and thick flanges for improved sealing. This one was run as-cast except for some minor port matching.

6 After dyno testing, we did a partial teardown to reveal the internal engine parts. McCarty Racing’s available dual-quad street tunnel ram is an extremely well-thought-out unit, with a large plenum, straight runners, and thick flanges for improved sealing. This one was run as-cast except for some minor port matching.

These new heads have benefitted from many technological updates that have occurred since the ’60s.The intake ports were reduced in volume slightly, and the floors were flattened in order to get the velocity up. Additionally, the chamber was completely redesigned to take advantage of the new heart-shaped technology that has increased quench area and greatly improved flame travel. The original design used what was considered “state of the art” for wedge-type heads back then, but computer modeling and the general march of technology has moved well beyond the original design, and McCarty took advantage of what is now out there.

The exhaust ports have also been redesigned, not only to increase the flow but also to put the intake/exhaust flow ratio back into a usable area. In order to accomplish this, the exhaust ports were redesigned using the latest D-port technology. While at a glance the ports resemble those used on the Edelbrock Pontiac heads, they are larger as-cast and are contoured to take advantage of 1.75-inch exhaust valves and larger. The Edelbrocks use a 1.66 exhaust valve as cast, and they do a good job of working with that size.

7 With exhaust manifolds being so unobtainable for Ram-Air V heads, McCarty Racing offers both conventional street and Tri-Y headers as part of its product line. The street headers shown here feature 2-inch primaries and a 3.5-inch collector. They are being developed for the more popular A- and F-body applications.

7 With exhaust manifolds being so unobtainable for Ram-Air V heads, McCarty Racing offers both conventional street and Tri-Y headers as part of its product line. The street headers shown here feature 2-inch primaries and a 3.5-inch collector. They are being developed for the more popular A- and F-body applications.

Though some later versions of the Ram-Air V used specific-design airfoils to go over the pushrod tubes, McCarty has so far resisted their use, as the improved port design increased velocity to such an extent that they aren’t a necessity.

The flow numbers are very impressive right out of the box at 360 cfm on the intake and 240 on the exhaust at 0.700-inch lift. McCarty also has an optional CNC port that flows 377 cfm at the same lift. A chart with specifics for the ported version is shown here for comparison.

Aluminum was chosen as a construction material over iron for a variety of reasons, including weight, ease of casting and machining, and of course, cost. Cast-iron is a lot more expensive to develop in a small-volume run such as this and offers no real benefit.

The intake manifolds are also fresh designs. The factory single four-barrel intake was a dual-plane design that didn’t increase intake velocity a significant amount, yet hindered overall airflow. McCarty’s design uses a single-plane design that is available in both standard Holley and Dominator versions, and is set up to work with EFI systems.

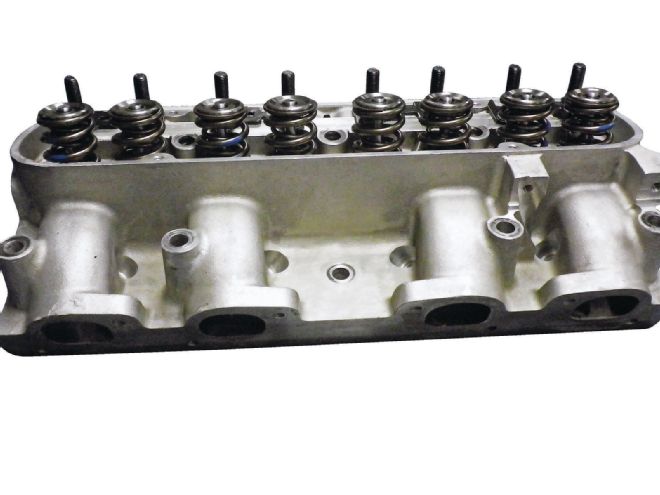

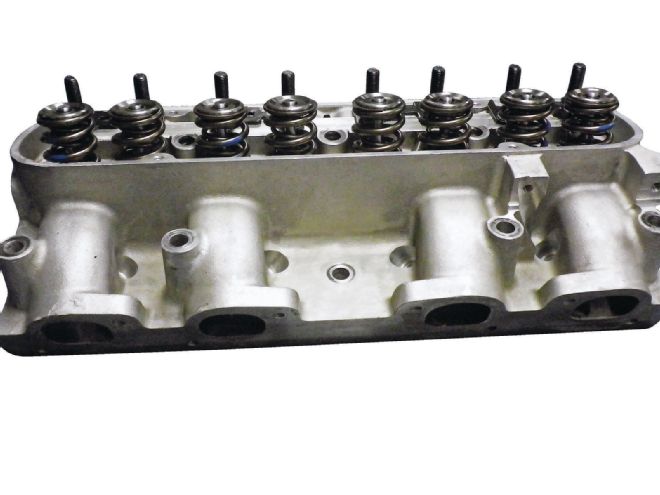

8 Aside from the fact that they are aluminum, the McCarty Racing Ram-Air V heads look very authentic. A little bit of Pontiac Engine Blue or black paint (the correct pre-production color) and no one would be the wiser.

8 Aside from the fact that they are aluminum, the McCarty Racing Ram-Air V heads look very authentic. A little bit of Pontiac Engine Blue or black paint (the correct pre-production color) and no one would be the wiser.

The dual-quad intake is referred to as a street tunnel ram and features a removable top, a large plenum, and very straight runners. For all-out race versions, a custom-fabricated sheetmetal intake is also available.

The Test Engine

In order to put these claims of improved performance and reliability to the test, Lynn worked with Tony Bischoff at BES to build an engine to showcase the performance potential that these heads and intake possess. “I wanted the short-block to be a relatively simple design that made use of entirely off-the-shelf parts that anyone could buy,” Lynn explained. “We used a production 455 block with an Eagle bottom-end, nothing at all exotic.”

9 Though it can’t be readily seen, the CNC-ported heads feature a flatter floor than the original Pontiac tunnel port design, which greatly increases flow velocity.

9 Though it can’t be readily seen, the CNC-ported heads feature a flatter floor than the original Pontiac tunnel port design, which greatly increases flow velocity.

Indeed, the short-block is something you’d see in the pits at any Pontiac drag race anywhere in the country. A ’75 455 two-bolt block was pressed into service. With a 4.22-inch bore and a 4.25-inch stroke, displacement checks in at 476 ci. A set of Ross forged pistons provide 11.27:1 compression when coupled with the 11cc valve reliefs and 73 cc combustion chamber. They swing on a set of Eagle 6.625-inch forged rods and an Eagle cast crank.

An SD Performance Mega Brace was added to strengthen the lifter bore area. About the only non-standard piece in the short block is the camshaft—a custom McCarty Racing billet roller was designed and built. It uses a 4-7 and 3-2 swap firing order and is now 18726543 instead of the normal 18436572. Duration checks out at 272/276 degrees at 0.050-inch lift and 0.720-inch lift with 1.65:1-ratio rockers. Crower mechanical roller lifters and Smith Brothers 3⁄8-inch-diameter pushrods are also employed.

10 These heads make use of new heart-shaped combustion chambers, which are a significant improvement over the stock bathtub-style units used on the originals. Improved flame travel and detonation resistance translates into improved breathing, as a stronger exhaust pulse results. With it comes better intake velocity and more power. Valve sizes for this engine are 2.19 inches for intakes and 1.75 for exhaust.

10 These heads make use of new heart-shaped combustion chambers, which are a significant improvement over the stock bathtub-style units used on the originals. Improved flame travel and detonation resistance translates into improved breathing, as a stronger exhaust pulse results. With it comes better intake velocity and more power. Valve sizes for this engine are 2.19 inches for intakes and 1.75 for exhaust.

The heads feature a mild CNC port and polish, and are fitted with 2.19/1.75-inch Manley valves, Harland Sharp stud-mounted 1.65:1 rockers, and Manley street/strip valvesprings. A Mallory Unilite distributor with an MSD Crank trigger comprises the ignition system.

The oiling system is equally simple but effective, consisting of a Melling high-volume oil pump, a windage tray, and a Milodon steel oil pan.

For this test, the McCarty Racing cast tunnel ram was used with a Kauffman crossover. It was port-matched to the heads and topped off with a pair of 750 Holleys prepared by Tom Vaught. McCarty bolted on a set of his custom headers that are built to order and feature a 2-inch primary tube and 3.5-inch collectors. Considering that Ram-Air V manifolds are absolutely impossible to find and the early JR headers are also nearly extinct, these new offerings are a necessary addition to the product line.

The Test

The 476 dual-quad Ram-Air V was bolted to the dyno at Tony Bischoff’s BES Racing Engines in Guilford, Indiana. A total of six pulls were made and the results were impressive, to say the least. Contrary to popular-held beliefs, once there is enough displacement to make use of those huge ports, the Ram-Air V heads can actually make quite a lot of torque, as the tests indicate.

11 The exhaust ports really don’t look like the originals at all, and as a result, flow much better. Intake-to-exhaust flow ratio on the original Ram-Air Vs was really out of balance. These revised ports really help get the ratios back in an acceptable number of 67 percent.

11 The exhaust ports really don’t look like the originals at all, and as a result, flow much better. Intake-to-exhaust flow ratio on the original Ram-Air Vs was really out of balance. These revised ports really help get the ratios back in an acceptable number of 67 percent.

A previous dyno session at BES had the engine running lean and power had fallen off somewhat. The Holleys were square-jetted with #77s and it was clearly not enough. For our session, the jets were jumped up to #82s all around and the first pull was recorded. In all honesty, a jump that high would result in a rich condition in most circumstances, but the idea was to jet on the safe side and dial it back from there, using the A/F ratio sensors and BSFC readouts to decide how far to jet down.

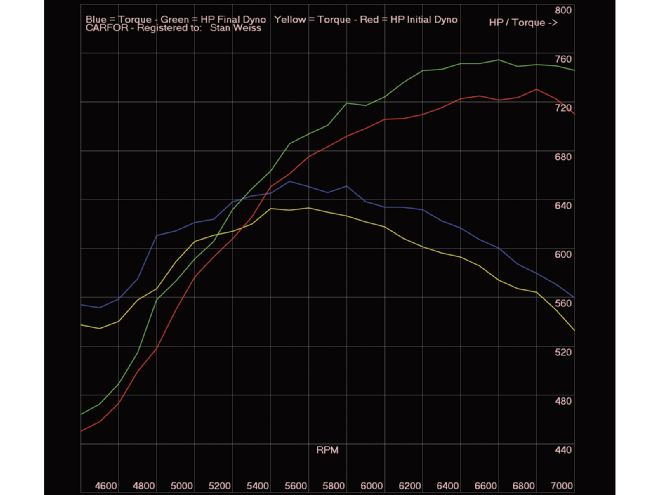

The first pull netted Lynn with a max horsepower of 730.4 at 6,800 rpm with 633.2 lb-ft of torque at 5,600. This was a nice fat number for anything that could be run on the street, but the combination was not optimized.

Four subsequent pulls were made with the horsepower numbers continuing to climb; the max fell just short of the desired 750 mark. Finally, the timing was set to 37 degrees; 79 jets were installed and the valve lash was set at 0.022 inch. The goal was exceeded—a max reading of 754.4 at 6,600 rpm was recorded, with a whopping 655 ft-lb at 5,500 rpm. Best of all the, the torque figures did not drop below 550 ft-lb for the entire pull from 4,400 to 7,000 rpm. That my friends, is a bullet motor and should be more than able to get a two-ton car into the 10s.

12 After the dyno pulls, the short-block looked great with no signs of head-gasket issues or any other problems. The pistons are Ross forged units.

12 After the dyno pulls, the short-block looked great with no signs of head-gasket issues or any other problems. The pistons are Ross forged units.

Even though the new McCarty Racing Ram-Air V heads and intakes come to market at a time where there are many choices for the Pontiac engine builder, few have the same level of breathing capability out of the box and none of them have that air of mystery and legendary status that the Ram-Air Vs possess. After more than 40 years, the Tunnel Port Pontiac finally gets its chance to shine.

“I’ve been a fan of the Ram-Air Vs since the early ’80s,” McCarty recalled

Dyno Results

Test 1: Baseline

Superflow dyno, Q-16, 116-octane fuel, #82 jets, 35-degrees total timing, all in at 1,800 rpm

RPM

Horsepower

Torque

4,400

450.3

537.5

4,500

458.1

534.7

4,600

473.2

540.3

4,700

499.3

557.9

4,800

518.1

566.9

4,900

549.6

589.1

5,000

576.6

605.7

5,100

593.1

610.8

5,200

607.9

614.0

5,300

625.6

619.9

5,400

650.6

632.8

5,500

661.2

631.4

5,600

675.2

633.2

5,700

683.4

629.7

5,800

692.0

626.6

5,900

698.4

621.7

6,000

705.8

617.8

6,100

706.4

608.2

6,200

709.8

601.3

6,300

715.3

596.3

6,400

722.6

593.0

6,500

724.9

585.7

6,600

721.5

574.1

6,700

723.6

567.2

6,800

730.4

564.1

6,900

722.6

550.0

7,000

710.1

532.8

The production block and two-bolt mains are clearly visible in this shot, as are the off-the-shelf reciprocating components.

The production block and two-bolt mains are clearly visible in this shot, as are the off-the-shelf reciprocating components.

Dyno Results

Test 6: Best Pull

Superflow dyno, Q-16, 116-octane fuel, #79 jets, 37-degrees total timing, all in at 1,800 rpm

RPM

Horsepower

Torque

4,400

464.1

554.0

4,500

472.5

551.5

4,600

489.3

558.7

4,700

514.7

575.2

4,800

558.1

610.7

4,900

573.2

614.4

5,000

591.4

621.2

5,100

605.8

623.9

5,200

631.9

638.2

5,300

648.9

643.0

5,400

663.4

645.2

5,500

685.9

655.0

5,600

693.7

650.6

5,700

700.8

645.7

5,800

719.1

651.2

5,900

717.1

638.3

6,000

724.2

633.9

6,100

736.1

633.8

6,200

745.7

631.7

6,300

746.8

622.6

6,400

751.5

616.7

6,500

751.5

607.2

6,600

754.4

600.3

6,700

749.1

587.2

6,800

750.6

579.7

6,900

749.6

570.6

7,000

745.8

559.6

14 The Ross pistons sit 0.005 below the deck, have 11cc valve reliefs, and provide 11.27:1 compression; the Eagle H-beam rods feature a production 6.625 center-to-center length.

14 The Ross pistons sit 0.005 below the deck, have 11cc valve reliefs, and provide 11.27:1 compression; the Eagle H-beam rods feature a production 6.625 center-to-center length.

CNC Port R/A-V Head Flow Tested on a 4.375-inch bore with stock valve placement. Lift Intake Exhaust 0.200 171 118 0.300 233 175 0.400 276 200 0.500 323 230 0.600 359 237 0.700 377 249 0.800 386 260 0.900 393 265

15 Here’s a dyno graph of the baseline and best pulls. McCarty feels that more valvespring pressure would allow for more rpm and power. Still, 754 is impressive.

15 Here’s a dyno graph of the baseline and best pulls. McCarty feels that more valvespring pressure would allow for more rpm and power. Still, 754 is impressive.

HPP Engine Buildup Worksheet

Year: ’75 455 stock-block, standard water jacket

Cubic inches after rebuild: 4.220 bore, 4.250 stroke 476ci

Engine built by: BES Racing Engines in Guilford, Indiana

Induction System

Carburetors: Dual 750 Holley by Tom Vaught

Intake manifold: McCarty Racing Ram-Air V cast Street Tunnel Ram with KRE crossover

Valley cover: KRE

Heads

Brand: McCarty Racing Street Ram-Air V alum. heads 356-T6

Combustion chamber size: 73 cc

Mods: CNC port job by BES Racing engines

Valves: 2.19 Manley 1.75 exhaust

Valvesprings: Manley BBC-style

Pushrods: Smith Brothers 3⁄8-in

Valve covers: Noah Performance reproduction chrome

Bottom End

Pistons: Ross street-type forged alum., multi-brow, flat-top

Rings: Total Seal 0.043x0.043x3⁄16 oil ring

Rods: Eagle forged 6.625-in

Compression ratio: 11.27:1 (with 0.040 gasket)

Crankshaft: Eagle 4.250 stroke, cast, cross-drilled, 3.25-in main, 2.20-in rod

Mods: Balanced/polished

Oiling System

Oil pump: Melling

Windage tray: Yes

Oil pan: Milodon standard street type

Camshaft

Brand: LSM billet-roller, custom per McCarty Racing

Duration at 0.050: 272/276-deg

Lift with specified rocker arms 0.720/0.720-in with zero lash

Rocker arms: 1.65:1 Harland Sharp

Ignition

Distributor: Mallory Unilite w/MSD crank trigger

Wires: MSD

Spark plugs: NGK V-Power

Total timing: 37-deg

Rpm that total timing is reached: 1,800 rpm

Exhaust

Headers: McCarty Racing R/A-V street headers

Primary size: 2-in

Collector size: 3.5-in

Pricing

Heads: $2,499 per pair bare with seats, guides and pushrod tubes

Custom port/polish: $2,499

Street headers: $799

Tri-Y headers: $999

Single four-barrel intake: $699

Dominator intake: $799

Tunnel ram: $999

Adjustable tunnel ram plenum top: $99

Stock-diameter cam: $429

55mm cam: $479