Since we began our Alternative Engine Series, we've been getting letters from prideful Poncho lovers asking, "When's our turn?" Pontiac created the musclecar, say the true believers, and HOT ROD should show it the respect it deserves! Some of you have even volunteered your engines, and though we are grateful, we have uncovered a streetable Pontiac blueprint that'll drop your jaws.

A visit to longtime Pontiac engine-builder Jim Taylor in his Revere, Pennsylvania, digs answered all of our questions. Taylor, a disciple of Pontiac guru Nunzi Romano and possessed of a quarter-century of Poncho speed secrets, is obsessed with reliable power. He has conducted endless research, both mathematical and physical, on dozens of possible Poncho combos. If anyone could get us 500 streetable hp for our self-imposed $4,000 limit, it would be Taylor.

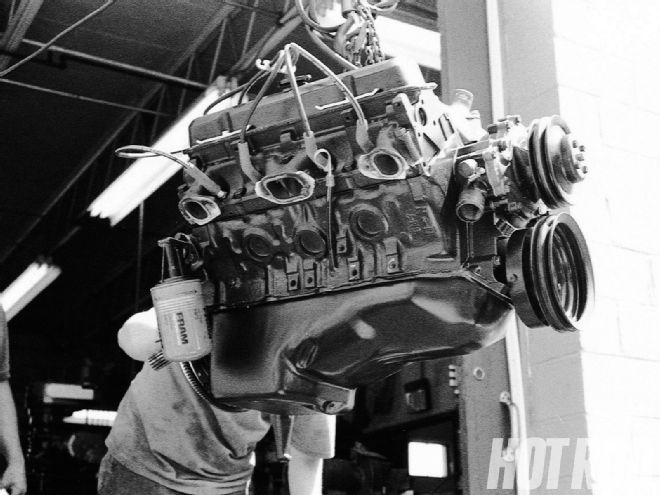

We built the foundation with a two-bolt 455 block out of a '73 Bonneville wagon. No need to cringe: Precious few 455s, save for factory H.O. blocks and super-rare Super Dutys, had four-bolt mains, so don't strain yourself looking for one. Though high-horsepower Pontiacs are known for weak mains and failures in high-revving applications (700-plus hp and 7,000-plus rpm), our goal wasn't enough to hurt a stock-block, even a two-bolter.

Finding a 455 isn't the trick you might think it is, either: If the boneyard doesn't have a motor you can walk away with for $150, you can buy a running donor car for $500, sell the body to a scrap yard for $100, and you're most of the way there. Our dollar figure in the "Shoppin' List" reckons $350 for a running engine and another three bills for machine work. If you find a cheaper engine, you're ahead of the game. Taylor uses Martyn Motors (Morrisville, Pennsylvania), a machine shop thoroughly versed in Poncho dreams, for all his close-tolerance work.

Since our dyno engine included Eagle forged rods, we put them in our "Shoppin' List." Pontiacs that operate above 6,500 rpm for most of their running time need forged connecting rods to stay together, but for a streetable engine like ours, they are largely an insurance policy. Cast rods were standard in most Poncho engines including the 455 H.O. (with a 5,600rpm redline), so a little cleanup and some new hardware will more than do the trick. Taylor is confident that he could have used prepped (deburred, resized, and shot-peened) stock cast rods fitted with ARP bolts and would have achieved the same results for hundreds of dollars less.

Although we used Eagle forged connecting rods (right), testing revealed that horsepower topped out below six grand. Taylor believes he could reduce cost, and duplicate our power numbers and reliability, with properly prepared stock rods.

Although we used Eagle forged connecting rods (right), testing revealed that horsepower topped out below six grand. Taylor believes he could reduce cost, and duplicate our power numbers and reliability, with properly prepared stock rods.

Every engine builder has secrets. One of Taylor's is the TFX Sciencam camshaft. TFX is a fledgling company that Taylor has been working closely with, and if our results are any indication, it could be a major player in the years to come. In short, Sciencams are ground to complement the airflow numbers of a specific cylinder head, so there's little chance of overcamming or undercamming the engine. Once TFX is aware of your particular engine combination-including rpm range, dis-placement, and airflow numbers-it will make you a solid-lifter cam (yes, solid lifter) perfectly suited to your engine's breathing capabilities.

Between the noise, the constant readjustment necessary to keep a solid-lifter engine happy, and the potential oiling problems that this configuration brings to the table, it's no wonder they fell out of favor in the '80s. So why use one a decade later? Simply, TFX has addressed all the problems of the solid-lifter cam. Perpetual valve adjustment is no longer necessary thanks to a tight 0.008-inch intake/0.016-inch exhaust lash (set cold) and 7/16 ARP rocker studs with 7/16 posi locks that maintain those tight tolerances. Between the tolerances and the Crane 1.5:1 roller rockers, it doesn't even sound like a solid-lifter cam through the valve covers. As for lubrication, Pontiacs with solid lifters tend to give a little too much oil up top, which usually requires some drilling, tapping, and the addition of a restrictor disc; TFX lifters come pretapped and feature a built-in restrictor disc that meters oil to the top of the valvetrain, which keeps more lube at the bottom end. Just plunk 'em in and go.

The TFX cam (right) has a wider lobe for longer duration starting at more than 0.200-inch valve lift.

The TFX cam (right) has a wider lobe for longer duration starting at more than 0.200-inch valve lift.

As for the advantages: A hydraulic flat-tappet cam profile cannot match the quicker opening ramps often used with solid-lifter units because the higher valvespring rates required by the rad-ical ramps would collapse the hydraulic lifter (a hydraulic roller cam for the Pontiac 326-455 engine does not exist, according to Taylor). Plus, hydraulic lifters can lose lift because of leakdown, which means that the valves don't open as much as they should. TFX claims nearly two dozen more horsepower for its solid-lifter cam over conventional hydraulic flat-tappet units of the same lift, duration, and lobe separation. Furthermore, there's plenty of vacuum to manage power accessories.

In some applications, solid lifters have a reputation for feeding more oil to the valvetrain than it needs. Drilling, tapping, and adding a restrictor to a solid lifter (left) has long been a way around this, but Taylor used the TFX S-series lifter (right), which incorporated these features out of the box, saving time and money.

In some applications, solid lifters have a reputation for feeding more oil to the valvetrain than it needs. Drilling, tapping, and adding a restrictor to a solid lifter (left) has long been a way around this, but Taylor used the TFX S-series lifter (right), which incorporated these features out of the box, saving time and money.

Our recipe also included #96 heads from a '71 400, which yielded a 9.4:1 compression ratio from our TRW forged replacement pistons. Taylor claims he can duplicate this engine's healthy performance with any D-port Pontiac head with 87cc-or-larger combustion chambers. Other castings that fit this profile are 6X, 64, 7K3, 7M5, 4X, and 5C heads (castings numbers are found on the center exhaust ports above the manifold). The 6X heads are popular and plentiful; most '76 to '79 350s and 400s had them as standard equipment. As a side note, the 350-cube 6X heads have 91cc combustion chambers while 400-cube 6X heads have a 101cc chamber. Also, 4X heads, used from '73 to '75 on 400s and 455s, are fairly common. Taylor sells complete ported heads in any of the above-listed castings for $950 out the door.

Naturally, we used as many stock Pontiac pieces as possible: windage tray, crankshaft, balancer, valve covers, oil pan, even the bearing-cap hardware, but be advised that much of this stuff must be replaced with stronger pieces if you plan for more power than we made. We also cheated a little with the carb, intake, and headers. The intake, an Edelbrock Torker I common-plenum unit, is no longer available new, but Taylor has a stockpile of them and sells them port-matched to the heads for a reasonable $125. The carb was a swap-meet special, a Holley PN 6109 four-barrel designed to work on a dual-quad tunnel-ram intake. Though the carb can be had for substantially less, a Taylor-rebuilt unit will run you $200. The headers we wanted to use came through too late from the manufacturer, but by a stroke of luck, we found some in the back of a junker in a Pontiac specialty parts yard. Thanks to Scott Silberg at ABE Auto Salvage in Bethlehem, Pennsylvania, for digging these suckers out. The headers' three-tube design wasn't optimal for what we wanted, but they got the job done. In the real world, typical swap-meet headers for Pontiacs fetch $75 or so.

Our intake was a port-matched, common-plenum Edelbrock Torker I. Alas, Edelbrock no longer makes this intake, so you're forced to go second-hand shopping. It shouldn't be tough to find one for $50 to $75 at a swap meet.

Our intake was a port-matched, common-plenum Edelbrock Torker I. Alas, Edelbrock no longer makes this intake, so you're forced to go second-hand shopping. It shouldn't be tough to find one for $50 to $75 at a swap meet.

We trucked our Poncho down to Trenton, New Jersey, to witness the moment of truth on longtime dirt-track-racer/engine-builder Fred Bitner's dynamometer. Our runs netted us more than anyone dared hope for-529.3 hp and nearly 560 lb-ft of torque (see charts). We never saw less than 400 lb-ft of torque anywhere in the rev range, we found 500 hp at 4,900 rpm, and we produced power for 1,000 rpm beyond that! As for the other half of our equation, a quick tally on the pocket calculator gave us a total of just under $4,000. Score a cheaper block, use prepped and cast connecting rods, and you're way below $3,500. You like that, Poncho fans? Yeah, we like it too. And once you drop this thumper into the Ventura, GTO, or 'Bird of your choice, you'll like the power and torque almost as much as you'll like seeing a Nova's grille in your rearview mirror.

Pontiac #96 Head Flow Numbers (at 28 inches of H2O) Valve Lift 0.200 0.300 0.400 0.500 0.550 Intake cfm, Stock 154 187 202 205 207 Intake cfm, Modified 141.5 186 220 238.5 238.5 Exhaust cfm, Stock 110 150 165 182 184

Shoppin' List BLOCK: 1973 Pontiac 455, two-bolt mains (YC-code), 0.030-inch overbore (462 ci), balanced, blueprinted for compression ratio and rod clearance, cylinders honed $650 PISTONS: TRW (PN L2359) forged flat-top replacement with floating wristpins $225/set RINGS: Sealed Power E-300K 30 $79/set CONNECTING RODS: Eagle forged steel, PN CRS 6625P3D $675/set ROD BEARINGS: Michigan Clevite 77 PN CB-758P $40/set HEADS: '71 #96 castings (96 cc); cleaned, port-matched intake; polished and massaged short turn; blended bowls; three-angle valve job; Nunzi's 2.11/1.77 x 5.100 stainless valves; TFX valvesprings; stock Pontiac pushrod guides and retainers; Crane locks, complete and ready-to-install $950 ROCKERS: Comp Cams 1.5:1 roller rockers, PN 1451-16 $125 PUSHRODS TFX PN D-5100, hardened $69 CRANKSHAFT: Stock Pontiac 4.210-inch stroke Free with engine MAIN BEARINGS: Michigan Clevite 77 PN MS-667P, Pontiac hardware $60/set CAMSHAFT: TFX Sciencam solid-lifter PN S-246 (246/246 degrees duration @ 0.050, 0.532/0.532 gross lift, 110-degree lobe separation) $150 LIFTERS: TFX S-series $105 CAM BEARINGS: Michigan Clevite 77 $20 TIMING CHAIN: Melling PN 40408 double-roller $65 INTAKE MANIFOLD: Edelbrock Torker I (used), port-matched $125 INTAKE GASKET: Mr. Gasket #502 (port template) $10 CARBURETOR: Holley 750 PN 6109 (used and rebuilt), jetted 77 front/79 rear $200 CARB SPACER: Competition Products, 1/2 inch, for Holley $7 IGNITION: GM HEI w/recurve $100 TIMING: 12 degrees initial, 34 degrees total at 2,400 rpm OILING SYSTEM: Stock Pontiac windage tray, Sealed Power oil pump PN 224-173R $60 EXHAUST: Mystery three-tube long-tube headers with 1 3/4-inch outer primaries and 3-inch collector (used) $75 GASKETS: Mr. Gasket Engine Gasket Kit PN S/P 260-1025 $65 BALANCER: New stock Pontiac $89 TOTAL: $3,944 (Shipping and assembly costs not included. Machining prices may vary in your area. Prices correct as of press time.)

Dyno Chart RPM HP Lb-Ft 2,700 240.1 475.2 2,800 257.7 484.3 2,900 274.1 491.6 3,000 285.8 495.5 3,100 296.2 497.0 3,200 305.1 500.3 3,300 317.6 503.6 3,400 332.7 510.0 3,500 348.1 516.1 3,600 360.4 522.2 3,700 372.9 527.9 3,800 384.6 531.0 3,900 397.5 534.8 4,000 410.6 537.8 4,100 424.0 543.8 4,200 436.6 548.3 4,300 450.2 552.7 4,400 464.7 556.6 4,500 475.8 558.7 4,600 484.6 553.2 4,700 490.8 547.8 4,800 495.6 541.2 4,900 501.0 535.8 5,000 504.8 529.2 5,100 508.9 523.7 5,200 514.2 517.2 5,300 517.9 512.8 5,400 521.7 506.3 5,500 524.5 500.9 5,600 526.3 493.2 5,700 528.2 486.1 5,800 529.0 477.9 5,900 529.3 469.2 6,000 529.1 462.6 6,100 528.0 453.9 6,200 526.0 445.2 6,300 522.6 435.4 6,400 516.9 423.9