There’s no buzzkill like a Jeep that overheats when you’re out on the trail, soaking in the beauty of nature and trying to mount the next obstacle. Or when you’re on the afternoon commute in traffic, for that matter. There is simply no good time for overheating, and for 99 percent of the Jeeps on the road, there’s no reason for it either. If you approach your cooling system with the same systematic approach as you do selecting gear ratios and tire sizes, it’s pretty easy to keep your engine cool.

First the basics: The engine creates heat. The more power the engine makes, and the harder you work the engine, the more heat is generated. That’s why a tow vehicle has a huge radiator—lots of power and lots of work. Some of the heat goes out the exhaust and some is radiated directly to the air, but most of the heat is removed from the engine through liquid coolant and transferred to the radiator. The radiator is designed to transfer as much of that heat as possible from the coolant to the air. The cooling fan draws additional air though the radiator to increase that heat transfer. It’s pretty simple, really.

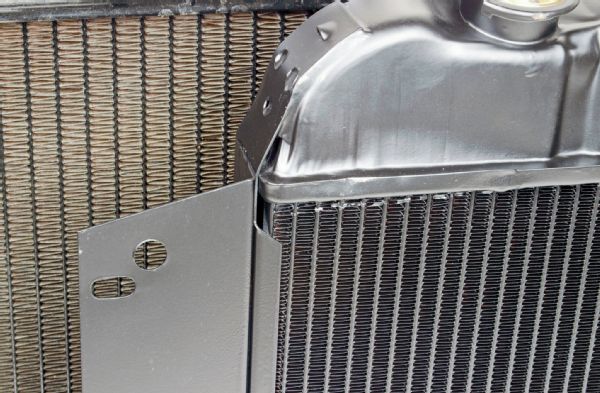

The radiator is one of the primary components in the cooling system. It’s quite easy to make a 100 percent increase in radiator coolant capacity by switching from a factory to an aftermarket radiator. Larger side tanks and going from one to two rows will get you there. The upgrade from the composite (plastic side tanks/aluminum core) to all-aluminum is better for cooling and durability.

The radiator is one of the primary components in the cooling system. It’s quite easy to make a 100 percent increase in radiator coolant capacity by switching from a factory to an aftermarket radiator. Larger side tanks and going from one to two rows will get you there. The upgrade from the composite (plastic side tanks/aluminum core) to all-aluminum is better for cooling and durability.

The issue that we often run into is that Jeeps have tight engine bays, typically small space for a radiator, and we like to stuff big horsepower engines into them.

There are a few factors when considering the right radiator for your Jeep. First is the efficiency of heat transfer. The old tech was to add “cores” to increase heat transfer. This refers to how many layers of tubes the radiator has. In traditional radiators, the tubes were 3⁄8-inch wide, and a 2-core radiator would have two rows of these tubes. The problem is that as you add another row, you decrease the efficiency of each row. So a 4-core radiator doesn’t provide twice as much heat transfer as a 2-core. The last core has hot air passing over it from the first 3 cores, and the thick radiator is more difficult to move air through. Most modern radiators use 1-inch wide cores and come in either 1- or 2-row configurations for improved heat transfer. The other factor in the radiator core is how many cooling fins are attached to the tubes and the spacing and design of the fins. This is a balance, but generally the more fins you have per inch while not restricting airflow, the more heat the radiator will transfer.

Another key element in the radiator is coolant capacity. Most of the time, the factory radiator was the smallest needed in order to cool the stock engine. A larger radiator was a waste of material and added weight. It’s typical for an aftermarket radiator to double the coolant capacity. Not only does this add more coolant to the overall system, it increases the amount of the coolant that is in the radiator at any given time where it is rejecting heat, instead of in the engine where it is absorbing heat.

Many original radiators are a down-flow design, meaning the coolant enters a tank at the top of the radiator and flows down through the core. More modern designs are cross-flow, with the tanks on the sides and the coolant flows from side to side. This results in more heat transfer because the coolant is in the radiator longer.

Many original radiators are a down-flow design, meaning the coolant enters a tank at the top of the radiator and flows down through the core. More modern designs are cross-flow, with the tanks on the sides and the coolant flows from side to side. This results in more heat transfer because the coolant is in the radiator longer.

The fan is the next part of the cooling system you will want to consider. The goal with the fan is to move the maximum amount of air through the radiator. The key, though, is that the air needs to go through the radiator, not around it.

Belt-driven fans can move a ton of air and typically work better with the engine running above 1,500 rpm. The higher the engine revs, the more air the fan will move. The challenge with most Jeeps is that the fan shroud is gone because the fan hit it while we were off-roading or we’ve done an engine swap and there wasn’t a fan shroud available. Without a fan shroud, air will take the path of least resistance, which is over, below, and anywhere except through the radiator.

That’s one of the things that make an electric fan attractive. The electric fan mounts directly to the radiator, only pulling the air through the radiator. The other advantage of an electric fan is that it can pull maximum airflow with the Jeep idling. Some people don’t trust the electronics, but we think the technology has proven itself over the last several decades.

The number of cores refers to how many rows of tubes are in the radiator core. With the radiator cap removed, you can see the tubes. This radiator uses two rows of 1-inch wide tubes. This is the current standard for high-performance radiators. Thicker, 4- and even 5-core designs with 3⁄8-inch tubes are more difficult to draw air through.

The number of cores refers to how many rows of tubes are in the radiator core. With the radiator cap removed, you can see the tubes. This radiator uses two rows of 1-inch wide tubes. This is the current standard for high-performance radiators. Thicker, 4- and even 5-core designs with 3⁄8-inch tubes are more difficult to draw air through.

However, not all electric fans are equally good at cooling. The size of the fan blade and wattage of the electric motor determine how much air the fan can move through how much of an area of the radiator. Aftermarket fans are rated in cubic feet per minute (cfm) of airflow. There is not a standard for testing this, but it’s a decent way to compare electric fans. For most stock engines, you’ll want at least 2,000 cfm and more like 3,000 cfm if you live in Phoenix and have air conditioning. Most Jeeps with mild V-8s swapped in can use fans with 3,000 cfm of airflow. More airflow is usually better for cooling, but the design of the fan makes a difference, and the higher the airflow, generally the higher the amperage draw, which may dictate an alternator upgrade.

There are several other items in the cooling system that are important to consider. We share more information on that in the photos and captions. The bottom line is that it’s easier than ever to keep the coolant in your system and the heat out. Feel free to remind us of that if you see us on the trail with the hood up, letting off steam.

You’ll hear “high efficiency” used a lot to describe a radiator. This has to do with the tube and fin layout. This U.S. Radiator (in front) features the company’s high-efficiency core, which uses 1⁄2-inch tubes on 3⁄8-inch centers, compared to most old brass and copper radiators which have the tubes mounts on 9⁄16-inch centers. This means more tubes and more contact with cooling fins for better heat transfer. U.S. Radiator offers various core designs to match what you need in a specific application.

You’ll hear “high efficiency” used a lot to describe a radiator. This has to do with the tube and fin layout. This U.S. Radiator (in front) features the company’s high-efficiency core, which uses 1⁄2-inch tubes on 3⁄8-inch centers, compared to most old brass and copper radiators which have the tubes mounts on 9⁄16-inch centers. This means more tubes and more contact with cooling fins for better heat transfer. U.S. Radiator offers various core designs to match what you need in a specific application.

Flex-a-lite offers bolt-in radiator and fan combinations for over 40 years of Jeeps, covering JK, TJ, YJ, XJ and even most CJs. These are available with and without an electric fan. The fan comes attached to the radiator, saving you time, and is already matched in size and airflow for the specific application. Their radiators include patented side-tank design that transfers heat 135 percent better than aluminum sheetmetal side-tanks.

Flex-a-lite offers bolt-in radiator and fan combinations for over 40 years of Jeeps, covering JK, TJ, YJ, XJ and even most CJs. These are available with and without an electric fan. The fan comes attached to the radiator, saving you time, and is already matched in size and airflow for the specific application. Their radiators include patented side-tank design that transfers heat 135 percent better than aluminum sheetmetal side-tanks.

The question of belt-driven versus electric fan is typically driven by opinion more than fact. The facts are that an electric fan mounts directly to the radiator, pulling all of the air through the radiator, and pulls max airflow, regardless of engine speed. Both of these points make electric an ideal cooling solution for a slow speed Jeep.

The question of belt-driven versus electric fan is typically driven by opinion more than fact. The facts are that an electric fan mounts directly to the radiator, pulling all of the air through the radiator, and pulls max airflow, regardless of engine speed. Both of these points make electric an ideal cooling solution for a slow speed Jeep.

There is more to choosing an electric fan than comparing airflow ratings. You want the shroud to cover at least 70 percent of the radiator surface, making a rectangular shroud like this that is part of what makes the Flex-a-lite Black Magic fan more desirable. Also, the fan motor and blade are located farther away from the radiator surface, pulling air through the entire shroud better than if the blade was closer to the radiator. All electric fans have a zone in the middle where the motor blocks airflow, which is reduced by moving the motor farther away from the radiator surface. Flex-a-lite found that this design of fan removes 40 percent more BTUs.

There is more to choosing an electric fan than comparing airflow ratings. You want the shroud to cover at least 70 percent of the radiator surface, making a rectangular shroud like this that is part of what makes the Flex-a-lite Black Magic fan more desirable. Also, the fan motor and blade are located farther away from the radiator surface, pulling air through the entire shroud better than if the blade was closer to the radiator. All electric fans have a zone in the middle where the motor blocks airflow, which is reduced by moving the motor farther away from the radiator surface. Flex-a-lite found that this design of fan removes 40 percent more BTUs.

If you run a belt-driven fan with a shroud, you still have quite a few choices. The flex fan shown at right will move quite a bit of air, but it will flatten out at higher engine speeds for reduced load, freeing up horsepower. However, some Jeeps need that airflow at higher engine speed (in sand dunes, for example) so a fixed-blade fan would be better in these applications.

If you run a belt-driven fan with a shroud, you still have quite a few choices. The flex fan shown at right will move quite a bit of air, but it will flatten out at higher engine speeds for reduced load, freeing up horsepower. However, some Jeeps need that airflow at higher engine speed (in sand dunes, for example) so a fixed-blade fan would be better in these applications.

How do you know how hot your Jeep is running? There are quite a few reasons that you should not trust the factory gauge. Get a good quality aftermarket gauge like this AutoMeter unit. Electric gauges are convenient for installation, but we’ve had issues with grounding and corrosion creating inaccurate readings, and in many applications, we prefer mechanical gauges that use capillary tubes.

How do you know how hot your Jeep is running? There are quite a few reasons that you should not trust the factory gauge. Get a good quality aftermarket gauge like this AutoMeter unit. Electric gauges are convenient for installation, but we’ve had issues with grounding and corrosion creating inaccurate readings, and in many applications, we prefer mechanical gauges that use capillary tubes.

Where you mount the sending unit makes a difference in the normal and hot readings on your gauge. For example, the cylinder head will have a higher temperature than the intake manifold, thermostat housing, or water pump. After you install a new gauge, note the readings during normal driving to determine what the normal range will be.

Where you mount the sending unit makes a difference in the normal and hot readings on your gauge. For example, the cylinder head will have a higher temperature than the intake manifold, thermostat housing, or water pump. After you install a new gauge, note the readings during normal driving to determine what the normal range will be.

What water pump are you running? More than likely, it’s an old stock unit or an inexpensive replacement from an auto parts store. Flow Kooler water pumps are designed to move more coolant, avoid aeration, and can increase system pressure, all contributing to better cooling through both flow and decreased air pockets from cavitation.

What water pump are you running? More than likely, it’s an old stock unit or an inexpensive replacement from an auto parts store. Flow Kooler water pumps are designed to move more coolant, avoid aeration, and can increase system pressure, all contributing to better cooling through both flow and decreased air pockets from cavitation.

The accessory pulleys can have a dramatic effect on cooling, especially at idle and low engine speeds. A popular engine performance upgrade that is detrimental to cooling is to run underdrive pulleys that slow down the speed of the water pump and the rest of the accessories. March Performance offers a series of pulleys with ratios designed to increase the water pump speed at idle, which is helpful for Jeeps used for rock crawling and other low-engine speed types of off-roading.

The accessory pulleys can have a dramatic effect on cooling, especially at idle and low engine speeds. A popular engine performance upgrade that is detrimental to cooling is to run underdrive pulleys that slow down the speed of the water pump and the rest of the accessories. March Performance offers a series of pulleys with ratios designed to increase the water pump speed at idle, which is helpful for Jeeps used for rock crawling and other low-engine speed types of off-roading.

Thermostats are another misunderstood cooling system item. Traditional thinking was to use one with a low opening temperature (160 degrees Fahrenheit, for example) or remove it altogether. If you’re running fuel injection, though, you’ll need a thermostat to maintain a minimum engine temperature for the EFI to operate in closed-loop. There’s quite a variety of quality in thermostats, so purchase a high-quality one rated to open at the temperature required by your EFI system.

Thermostats are another misunderstood cooling system item. Traditional thinking was to use one with a low opening temperature (160 degrees Fahrenheit, for example) or remove it altogether. If you’re running fuel injection, though, you’ll need a thermostat to maintain a minimum engine temperature for the EFI to operate in closed-loop. There’s quite a variety of quality in thermostats, so purchase a high-quality one rated to open at the temperature required by your EFI system.

Vehicles built in the last 30 years or so use an expansion or overflow tank as an integral part of the cooling system. You are supposed to top off the system with this tank. If you remove the coolant from the radiator for whatever reason, you’ll need to purge the air from the system by letting it cycle through warming up and cooling off several times. Vehicles like XJs, where any of the coolant passages in the engine are higher than the radiator, are particularly hard to purge, and you may need to park the vehicle on a hill with the radiator higher than the engine to get all of the air out of the system.

Vehicles built in the last 30 years or so use an expansion or overflow tank as an integral part of the cooling system. You are supposed to top off the system with this tank. If you remove the coolant from the radiator for whatever reason, you’ll need to purge the air from the system by letting it cycle through warming up and cooling off several times. Vehicles like XJs, where any of the coolant passages in the engine are higher than the radiator, are particularly hard to purge, and you may need to park the vehicle on a hill with the radiator higher than the engine to get all of the air out of the system.

The radiator cap is another simple item that we often see problems with. The cooling system is pressurized; a 50/50 mix of water and coolant boils at 220 degrees Fahrenheit without any pressure, and the boiling point increases about 2 degrees for each pound of pressure in the system. Using a 16-psi cap raises the boiling point to about 250 degrees. Increasing the pressure beyond what your cooling system is designed for can cause leaks or failures elsewhere in the system. But if you’re factory cap was rated at 20 psi, and you have an 11-psi cap on it now, you’ve decreased the capability of your cooling system.

The radiator cap is another simple item that we often see problems with. The cooling system is pressurized; a 50/50 mix of water and coolant boils at 220 degrees Fahrenheit without any pressure, and the boiling point increases about 2 degrees for each pound of pressure in the system. Using a 16-psi cap raises the boiling point to about 250 degrees. Increasing the pressure beyond what your cooling system is designed for can cause leaks or failures elsewhere in the system. But if you’re factory cap was rated at 20 psi, and you have an 11-psi cap on it now, you’ve decreased the capability of your cooling system.