Harry Wagner

Contributor

Harry Wagner

Contributor

Last month we went over the parts that LA Speed used to build us a 460 Ford engine with gobs of torque for off-road use (“Ford Big-Block Power”). While the engine wasn’t exactly cheap, it was still less expensive than more exotic options and only marginally more expensive than rebuilding the original 351M engine. Plus, L&L Products offers everything we needed to perform this engine swap so we can spend less time in the shop and more time out on the trail.

Nate’s Precision used a forklift to stab the engine into our F-150, and Nate Jensen built us a high-clearance exhaust with components from Dynomax. Our only regret was doing the whole swap with the 41-inch Pit Bull tires on the truck. Some 31-inch-tall rollers would have made it much easier to access the engine bay.

Getting the truck fired up was surprisingly simple thanks to the parts from L&L Products. Nate’s Precision added accessories to the front of the engine, built the exhaust, and plumbed the fuel system with an electric Holley pump in just a few short days. While it might not be the most exotic engine swap for our F-150 it is hard to beat the bang-for-the-buck offered by the 460.

“Thanks to L&L Products we can spend less time in the shop and more time on the trail.”

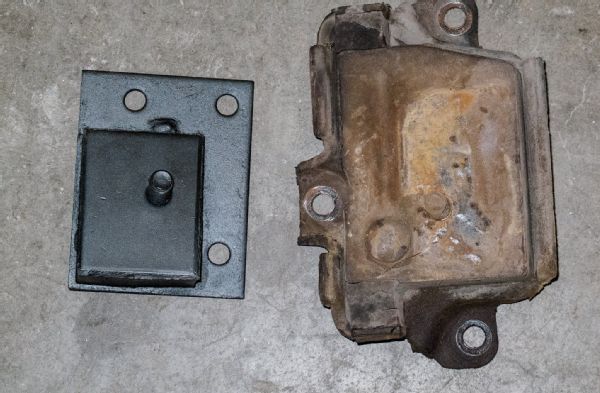

The L&L Products motor mounts allowed us to bolt the 460 directly into our F-150 without having to reposition the transmission or transfer case. The mounts use durable rubber to minimize vibrations. How durable? L&L is so confident in them that these motor mounts come with a lifetime warranty.

A poorly shimmed starter had eaten the teeth off our old flywheel, which needed to be replaced anyway to mount to the new engine from LA Speed. Pre-’79 460s were internally balanced, but our newer engine required an externally balanced flywheel. L&L Products offer both styles for whichever 460 you choose.

The heavy-duty clutch and pressure plate from L&L Products are designed to fit into the bellhousing of our NP435 transmission and include all required fasteners. The clutch holds up to the power from our 460 without being overly grabby, making it perfect for a truck used off-road.

Our old gas tank was weeping fuel so we took the opportunity to double our fuel capacity with a 38-gallon tank from LMC Truck. LMC offers strap extensions and new sending units as well, although we did have to modify the sending unit for the deeper tank.

Jeff Donker at LA Speed recommended that we run an electric fuel pump, so we went to Summit Racing Equipment and picked up a Holley pump. Nate’s Precision mounted the fuel pump on the framerail just forward of the rear-mounted tank. The external pump is louder than an in-tank pump, but it is also easier to access should you need to perform troubleshooting or repairs.

Since the larger tank hangs below the frame, Nate’s Precision built us a beefy skidplate out of 1⁄4-inch plate. The straps on the tank were retained so you could drop the skidplate independent of the tank if necessary.

We initially tried to install the engine with the headers already bolted on, but we ran into fitment problems. Removing the headers to get the motor in place and then adding them in the engine bay proved to be much easier.

L&L Products offers a variety of exhaust headers for not only Ford engines but GMs and Dodges as well. They all use 1⁄2-inch-thick flanges and come with gaskets and 12-point hardware. We chose the three-quarter–length headers that exit inside the framerails. Ours are finished in high-temp black paint, but ceramic coating is also available from L&L as an option.

Nate’s Precision owner Nate Jensen knows what is important when building an exhaust for a vehicle used off-road. He built our exhaust out of components from Dynomax that are tucked high between the framerails and exit above the frame just behind the cab.

Dynomax is best known for complete bolt-on exhaust systems, but that was not an option for us. We ordered up a variety of mandrel bends and tubing that Nate’s Precision used to create a 21⁄2-inch into single 3-inch exhaust. The collector for the two sides sits just behind the bellhousing. This left us enough room for a Dynomax Mini Bullet and Ultra Flo mufflers, which are mounted in series to quiet down the 460.

A big engine needs a big air filter, and since a 6-inch tall K&N element would still clear the hood, that is what we mounted on the top of our Holley Truck Avenger. The foam pre-filter is added insurance in the dirt and looks fast even when sitting still.

L&L Products offers brackets to retain the accessories from your old engine, but we wanted to upgrade our steering pump to a “canned ham” P-pump, so we replaced the accessory drive with a serpentine belt system from March Performance.

The new powerplant provides plenty of grunt for crawling on the trail and has the ability to catapult our big, heavy truck through the mud and on the road. A camshaft with more duration would likely provide even more horsepower, but we weren’t willing to sacrifice idle quality or low RPM torque.

Getting the Most Out of Our Truck Avenger

The aluminum Holley Truck Avenger we ran worked well right out of the box, but there was still some room on the table for minor improvement in a couple of areas. The truck ran rich at idle and had a slight stumble when you accelerated from a stop.

Fortunately carburetors are easy to adjust. Holley has a series of excellent how-to videos on its YouTube channel to walk you through the process (youtube.com/user/Holley Performance). Going down two jet sizes on the primaries cured the rich condition, and a larger 50cc accelerator pump took care of the flat spot. We were able to swap out the parts in minutes with simple handtools.

PhotosView SlideshowSpecial Thanks To:

LA Speed

Olathe, KS

800.658.1048