Pete Trasborg

Brand Manager, Jp

Pete Trasborg

Brand Manager, Jp

Many on-board-air systems come into existence directly after a guy takes his Jeep to a shop for an estimate on fixing the A/C system. All too often, the shop comes back with a quote of right around $2,000 when the parts total is well under $1,000. Anyone who can fix a brake system or power steering system can fix an A/C system.

Many shops swear by the thermometer in the vent when in reality the air temp coming out of the A/C system depends a great deal on the intake air temp. A typical system will only drop the air temp 20 degrees each time the air flows across the evaporator, and you know if your A/C is working well enough to keep you cool without some thermometer telling you.

Many shops swear by the thermometer in the vent when in reality the air temp coming out of the A/C system depends a great deal on the intake air temp. A typical system will only drop the air temp 20 degrees each time the air flows across the evaporator, and you know if your A/C is working well enough to keep you cool without some thermometer telling you.

The reason the shops get away with charging so much is because so many of us don't really understand the automotive (or any) A/C system. It really isn't any more complicated than many of the systems we already understand, we just haven't had it explained to us in the right way.

When I scored my new Comanche, as with every other Comanche I'd ever owned, the A/C didn't work. With this truck, it was because the condenser was hammered from an accident. Even I could see that. Like with the other MJs, I went to a few shops and got the $2,000 estimates as expected, so I decided to see if I could fix it myself.

A quick Internet search turned up Jeep Air. I sent an email about the shops charging too much, how I wanted to figure it out for myself, and how I needed some tech help. I then got a quick response. I was planning on doing this one outside the magazine; it would keep Cappa and Hazel from razzing me too much and I wasn't sure it was really worth a story, so I didn't include my title, my job, or anything (I was just some guy off the street).

The response I got floored me. The guy at Jeep Air responded with things like, "I hate that shops take advantage of the consumers," and "It would literally take under $700 to replace every part in that A/C system," and "I'm actually working on a book that covers this very subject right now." I was further shocked to see that the email was written by the CEO of the company himself, Jon Delucia.

I wasted no time in wasting his time asking all kinds of technical questions, and he batted every one of them back to me with clear and concise answers. I soon came to the realization that A/C wasn't that hard to understand, explained to Jon who I was and what I did, and asked if he wanted to help with a story. He agreed immediately and further decided the only way to really learn was to do it hands-on, so he flew out to Jp magazine's corporate headquarters to share 19 years of A/C repair and diagnosis with all of us.

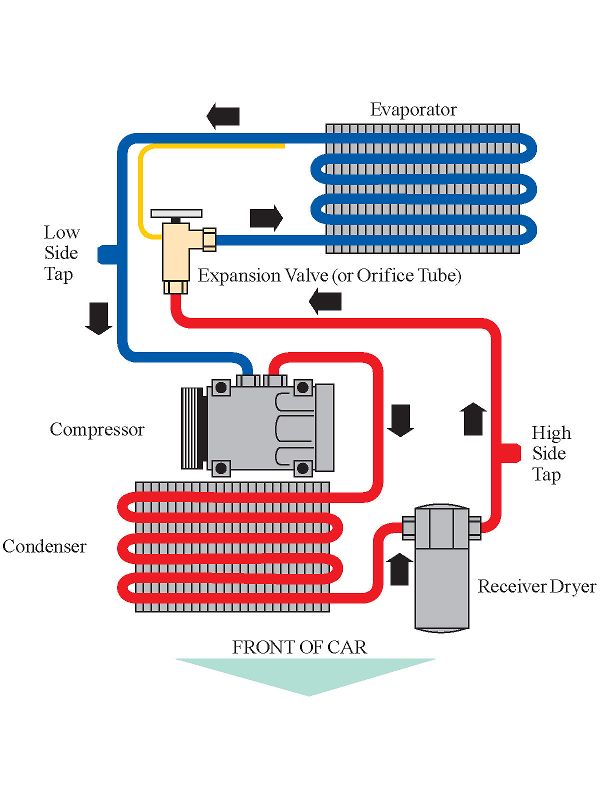

This flow chart shows both the high-pressure (red) and low-pressure (blue) sides of the A/C system as well as each component's location. If you are piecing a system together from junkyard parts, you'll need to make sure the parts are in this order or it just won't work.

This flow chart shows both the high-pressure (red) and low-pressure (blue) sides of the A/C system as well as each component's location. If you are piecing a system together from junkyard parts, you'll need to make sure the parts are in this order or it just won't work.

So join us on the other side of the shroud of A/C mystery as we team up with Jeep Air to explain the ins and outs of A/C systems and explain symptoms you might see when parts go bad.

Want More?

Jon Delucia is working on a book that goes much more in-depth than we were able to here and it should be available soon after you read this. Also, Jon sent us a huge four-page, single-spaced mini-story in response to some of our questions, which we used in this story. If you want to see the entire four-page answer which gives a bit more background and other information, we've got Jon's story right here on the following pages, starting on Page 2!

Written by: Jon Delucia

Nostalgic Air Parts, Inc.

www.jeepair.com

Automotive air conditioning systems have not changed much over the past 40 years. The system still has all the major components that were used when a/c first became common on automobiles. There are five major components to an automotive a/c system: the compressor, evaporator, condenser, accumulator or drier, and expansion valve or orifice tube. The components all have a task to perform while working together as a team to produce cold air.

The first major component of the a/c system is the compressor. A compressor is made of two parts, the compressor, and the clutch assembly. The compressor has one job in an a/c system. It is used to pump refrigerant and oil throughout the system. The compressor is the starting point for the high side of the a/c system, and the ending point for the low side. The compressor sucks refrigerant and oil into the body on the low side, which is where the name suction side comes from. On the discharge side or high side the compressor is pushing the oil and refrigerant out at a higher pressure. The compressor has a clutch assembly attached to the front. The clutch assembly is made up of three parts (on most cars today); the coil, the pulley, and the hub. The coil is simply a magnet that gets power from the a/c system’s control head. The pulley is the part that has the belt routed around it. The pulley has a bearing pressed into it that rides on the compressor’s nose. The hub is located on the front of the clutch assembly; it is bolted to the shaft coming out of the compressor. The hub is the part of the clutch that actually spins the internals of the compressor to achieve the pumping action needed to move the refrigerant and oil. The hub is normally mounted with a nut or bolt on the front of the compressor. The shaft of the compressor will have splines or keyway to keep the hub and the shaft locked together. The way the complete assembly works is as follows: When the driver turns on the a/c the coil will magnetize. The pulley is always turning because the engine is turning the belt that is attached to it. When the coil is magnetized the hub is then pulled against the pulley to spin the compressor shaft. At this time the compressor will pump. On most vehicles only two things cause a clutch assembly to fail. Lack of oil in the compressor (from a leak) or wear over time. On Jeeps with a Sanden compressor (Wranglers, Cherokees, Liberties) the compressor clutch’s metal surface will wear down increasing the clutch gap. The clutch gap is the gap between the hub and the pulley. As the metal wears down, the coil is not able to pull the hub to the pulley. This normally happens on Jeeps at 90,000 to 110,000 miles. The most common sign of this problem is the vehicle’s a/c cools when it is first driven with the a/c on then it quits after a while. You can then turn off the a/c for 30 or so minutes and reuse the a/c. The other cause of clutch failure is a leak in the system. The compressors on most Jeeps are similar to an engine; they have pistons, and valves and they always have to have lubrication. If a system develops a leak in any component the refrigerant will escape as well as some oil. As oil and refrigerant leave the system the compressor will starve for lubrication causing the metal on metal friction to produce severe heat. The heat in turn burns up the clutch assembly. The first part of a clutch to burn up is the bearing inside the pulley. The bearing is sealed with grease; heat will melt the grease causing the pulley to get hot which in turn heats up the coil melting the epoxy that holds the metal coils inside. Then the hub’s rubber dampeners melt. The misdiagnosis of this problem by the majority of repair shops is to replace the clutch assembly rather than fix the problem. When a clutch burns up it is because something caused it to. The only time a clutch should be replaced is when they wear out due to high mileage.

The evaporator is a component that operates on the low pressure side of the a/c system. The evaporator is normally located on the inside firewall of the Jeep behind the glove box on. The evaporator is encased in the plenum or evaporator housing. The housing also contains the heater core, the blower motor, and the blend doors for mixing the outside and inside air, and temperature. The evaporators function is to get the heat out of the vehicle, hence the term heat exchanger. The way an evaporator works is by pulling warm air across the fins and tubes of the core thus removing hot air from the vehicle, which allows cold air to exit the evaporator core into the ventilation system. The air coming out of the vents is the same air that is in the vehicle just without any hot air. The best analogy is when you are in a house in the winter, you exit the house feeling warm, and after a few minutes you start to feel cold. The outside air is removing the body heat from your body to make you feel cold. The evaporator’s functions are to convert the refrigerant (R-12 or R-134a) into a vapor from a liquid form, and to remove the heat from the air inside the vehicle. The refrigerant (Freon) in the evaporator has to exit in a vapor form in order to pass through the compressor. If the refrigerant enters the compressor as a liquid it can cause damage to the internals of a compressor. A compressor is not designed to pump liquid refrigerant and oil. Evaporators were originally made from copper, as Jeep air conditioning systems became more efficient the evaporators were made out of aluminum as they are today. Copper evaporators do not leak unless they are physically punctured, or they have a hole rubbed in them from movement inside the case. Copper evaporators are not as efficient for getting rid of heat, so aluminum was introduced. Aluminum evaporators work much better with R-12 and R-134a refrigerants, but they develop leaks a little easier. There are two major causes of leaks in aluminum evaporators. The first is caused by the blower motor. The blower motor has copper wires on the armature of the motor. As the motor runs the copper flakes off in micron sized pieces, these pieces are blown into the evaporator core where they can cause a reaction with the aluminum. The reaction leads to the copper eating into the aluminum causing pin-hole leaks. The second cause for leaks in aluminum a/c components is from moisture in the a/c system. If moisture mixes with R-12 or R-134a in the system it can create an acid that will eat away the aluminum from the inside out, this will be covered more when we speak about driers and accumulators.

The last component on the low side of the a/c system is the expansion valve, or orifice tube. The expansion valve and orifice tube both perform the same function in the system. They are used on two different types of systems. Orifice tubes are used on CCOT (Cycling Clutch Orifice Tube) systems which use an accumulator, not a drier. The orifice tube is used to meter the refrigerant and filter debris in the system. The expansion valve meters the refrigerant, while the drier filters debris. The purpose of the orifice tube and expansion valve is very similar. The two parts are the changing point from high pressure to low pressure in the system. If there is a problem with the high side of an a/c system is it not an expansion valve or orifice tube problem. If the low side has problem it most likely is an expansion valve or orifice tube problem. The most common sign of a clogged or damaged valve or tube is a low pressure on the low side (less than five pounds) or the low side is in a vacuum. If the high side is 300 psi it does not have anything to do with the expansion valve. The function of both the tube and the valve is to take the liquid refrigerant in the system and reduce it down to a mist before entering the evaporator. If this process does not happen the refrigerant will flood the evaporator causing the a/c system to not operate properly. The misting of the refrigerant allows the evaporator to transform the refrigerant at a faster and more effective rate into a vapor.

If the system uses an orifice tube it will have an accumulator. The accumulator is on the low side of the system at the outlet of the evaporator, and is much larger then a drier. The accumulator is designed to accumulate or store excess refrigerant and to dry the refrigerant. The accumulator contains desiccant to keep moisture out of the system. If liquid passes through the evaporator the accumulator will catch the excess liquid to help avoid damaging the compressor. The filter drier used on expansion valve system are very similar to an accumulator except they do not accumulate refrigerant. The drier is on the high side of the a/c system, and is between the exit side of the condenser and the entrance of the evaporator. The drier has a pipe on the entrance side that opens up to the diameter of the drier. Inside the drier is desiccant that is held in place by two pieces of metal with small holes that allow refrigerant and oil to pass. The desiccant is approximately 1-1/4” thick (approximately 8 ounces) which filters out debris, and dries the moisture out of the system. The liquids pass through the desiccant into the bottom of the drier, where a tube picks up the refrigerant and oil from the bottom and sends it out to the expansion valve. The desiccant in the accumulator and drier are very crucial in eliminating the moisture. This is the reason the drier and accumulator should be changed whenever the system is opened, and the reason an accumulator or drier should always remain capped until the system is ready to be charged.

The final major component of the a/c system is the condenser, which is on the high side of the system. The condenser has become the most crucial part of the system since the industry started using R-134a refrigerant. The condenser’s major function is to condense the refrigerant from a vapor to a liquid. The compressor needs the refrigerant to pass through it as a vapor, the evaporator needs the refrigerant to enter it in a liquid mist form, and the condenser is used to help change the physical form for the system to operate properly. The condenser has to be in a location where airflow can pass through its fins, normally in front of the radiator. The condenser is designed to allow the vapor from the compressor to enter at the top, as the refrigerant flows down to the bottom with air passing the fins the refrigerant can condense into a liquid. If you block airflow of the condenser the a/c system can be affected. If the refrigerant does not convert from a vapor to a liquid it will not enter the evaporator as a liquid which will cause the a/c system to not cool. The condensers used forty years ago for R-12 are not as efficient as the condensers made today but in our facility we still use the old tube and fin style condensers as well as serpentine and achieve a vent temperature of 32-40 degrees out of the vents. For most Jeeps made pre-1996 there is not a new parallel style condenser available so you have to make the original design work with R-134a.

All a/c systems use three types of three types of connections to seal the fittings. Many years ago there were flare fittings. Flare fittings have a cone shaped head on the male side and an inverted cone shape on the female side. The fittings fit together to make a seal where the cones meet. As technology advanced all auto manufactures changed the systems to o-ring style fittings. The o-ring fittings use a small rubber o-ring to make the seal, today most Jeeps use a spring lock, or quick disconnect fitting. This fitting uses two or three o-rings to make the seal but the fittings are not threaded together. There is a male fitting with o-rings on it, and at the end a coupling holding a spring. The female end has a flared end that slides under the spring to lock it into place, there are special tools required to release this connection. All three connections are sealed at the connection of the fitting not the threads, so thread sealer, or Teflon tape are not needed. When a fitting is not sealed at the threads like water fitting in the block thread sealers are not required. It has been said that o-rings used with R-12 will not work with R-134a, after years of research it has been found out that this is not true unless the system is using a gasket that is not black Nitrile or green HNBR.

There are two problems with refrigerants and oils today. The two problems are misleading information and using the products incorrectly. Oil in the a/c systems has changed over the past 40 years. We started with mineral oil for R-12, then the industry made a temporary substitute while the industry starting using R-134a, now all cars are using PAG oil. PAG oil is made in different viscosities for different vehicles. Jeep systems use PAG 46, or Sanden PAG 15. In our facility we have used PAG oil with R-12 and have never seen any adverse affects, so we recommend using PAG in every system. Most Jeep systems require 6-7 ounces of oil if they do not have rear a/c. If you add to much oil the system can overwhelm the refrigerant causing it not change states as necessary for the a/c to work properly. If too much oil is added it can clog the expansion valve and cause the compressor to malfunction.

The refrigerant used in automotive a/c systems has changed over the last 20 years. The reason for this change is because of the harm done to the ozone layer. R-12 refrigerant is a carbon based refrigerant that contained CFC’s which created holes in the ozone layer, the holes increase the sun’s UV rays which can damage our environment. In 1993 the government mandated that every new car use a substitute refrigerant called R-134a. The substitute refrigerant was to be in use for 15 years until a new better alternative was available. During the 15 year period the industry developed many new parts to make auto a/c work very well. Changing oils, and the condenser’s style helped contribute to the cold air you feel inside every new vehicle on the road today. When people tell me R-134a doesn’t get as cold as R-12 I tend to laugh. An a/c system can only get down to 32 degrees Fahrenheit. If the evaporator coil gets any colder than 32 degrees the water that runs off of the coil will freeze. The freezing water will block airflow to the vents, and eventually cause the compressor to starve for oil. As for R-134a being as cold, I have had a/c systems down to 26 degrees out of the vents. It will get as cold, but it may take a few seconds longer to feel at the vents. R-134a condenses at a higher pressure; this is why the condensers were redesigned. The new condensers have a larger surface area for condensing, with the same overall size. When you read about a product that says it will allow the vehicle to get 20 percent colder do not believe the hype. If you get an a/c system that is functioning correctly and blowing 38 degrees out of the vents it is not capable of blowing 20 percent or 7.6 degrees colder. The lower temperature would cause the evaporator to freeze up. The key to making any a/c system blow cold on the hottest days is to make sure it has the nothing blocking the condenser’s air flow, the system has the proper refrigerant charge, and the system has the proper amount of oil in the system. On a final note about the system, we get questions about stop leak. Our advise is do not use it, we have seen stop leak cause thousands of dollars in damage. Stop leak is designed to gel up when it mixes with outside air. When the system is taken apart for a repair the stop leak will gel up in the entire system causing blockage that cannot flushed or cleaned out. It is less expensive to fix the leak rather then trying a quick fix solution.