Ken Brubaker

Senior Editor, Four Wheeler

Ken Brubaker

Senior Editor, Four Wheeler

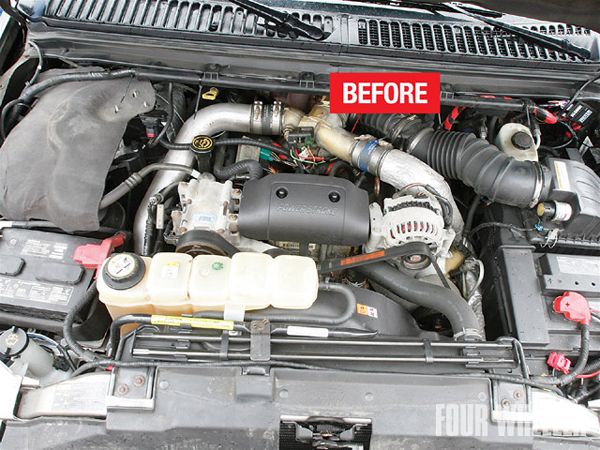

Have you ever wondered how hard it would be to swap a 2003 5.9L Cummins 24-valve diesel engine in place of a 7.3L Power Stroke diesel in a 2002 Ford Excursion? Well, when we heard that Attitude Performance technician Tony Zuccarello was planning this exact swap, and he was retaining the Ford 4R100 transmission, we were intrigued. Hence, we made plans to follow the install to see how it all came together. In the end, some aspects of the swap were far easier than we expected, while others were challenging to say the least.

It took approximately 20 hours of advance research and parts procurement before the actual installation of the Cummins began. Zuccarello says he has about the same amount of hours into the actual physical swap.

It took approximately 20 hours of advance research and parts procurement before the actual installation of the Cummins began. Zuccarello says he has about the same amount of hours into the actual physical swap.

So why would someone want to do this swap? Well, aside from having a unique vehicle, Zuccarello says he was looking for "improved performance and better fuel economy than the 7.3L Power Stroke can provide in this vehicle." He also noted that the Cummins is less expensive to modify and parts are more readily available compared to the Power Stroke. Zuccarello should know, he owns several diesel light trucks and he has wrenched on vehicles for over 32 years, including 10 years at a GM dealership.

One thing Zuccarello found out quickly is that there is no complete step-by-step "kit" available to do a swap like this. There are just too many combinations. There are basically three generations of the Cummins light truck engine and those can be mated to a slew of transmissions, for instance. The upside is that many of the major swap components are available through the aftermarket.

1. Zuccarello found a complete Cummins engine, with turbo, intercooler tubes, fan, pulleys, and alternator, at a salvage yard in Chicago. It came out of a wrecked pickup, which showed 127,000 on the odometer.

1. Zuccarello found a complete Cummins engine, with turbo, intercooler tubes, fan, pulleys, and alternator, at a salvage yard in Chicago. It came out of a wrecked pickup, which showed 127,000 on the odometer.

Nonetheless, Zuccarello spent a significant amount of time searching diesel-oriented Internet forums for general swap info. He also utilized the Internet, local shops, and his own ingenuity to procure the smaller hard parts needed to complete the conversion.

Over the next few pages we'll show you the highlights (and hurdles) of this specific conversion. Bear in mind that diesel swaps such as this vary significantly in time investment and parts depending on your experience and the vehicle and engine being mated together. The goal here is to give you a basic idea of what a swap like this entails and what's available in the aftermarket should you wish to undertake a conversion such as this.

5. Zuccarello chose to use a Ford 4R100 automatic transmission instead of a Dodge transmission, so he installed an adapter plate from DeStroked to mate the two. If you're not familiar with DeStroked you need to be if you're considering a Cummins conversion because they're specialists in this area. Their product line includes, but is not limited to, an array of adapters that enable the Cummins to be mated to a variety of transmissions. This plate is designed for a perfect fit and is made from 100 percent billet aluminum for maximum strength, reliability, and durability. It includes mounting bolts.

9.As noted earlier, Zuccarello used a Ford 4R100 transmission. Not just any 4R100, but a stout unit built by Brian's Truck Shop. This shop is legendary for custom-built, mega heavy-duty E4OD and 4R100 transmissions. This 4R100 has been upgraded with a slew of components to improve its durability and performance. Zuccarello could've swapped in a Dodge transmission and that would've saved the cost of the adapter plate and transmission controller (we'll get to the controller a bit later), but he wanted to go with the Brian's Truck Shop-built trans due to its proven durability. He had been running the trans in a Super Duty pickup behind a Power Stroke for over five years with no problem. Before installing it behind the Cummins, he had Brian's Truck Shop go through the trans and update the internals as well as match the torque converter to the Cummins engine. To fit the trans behind the Cummins he had to notch out the mounting brackets to move the trans rearward about an inch to compensate for the longer Cummins engine. Even with the relocation of the trans, he was able to use the Excursion's stock driveshafts with no modifications.

10. The Ford 7.3L engine wiring harness had to be modified to make the dash gauges function. Zuccarello ended up using the coolant temp and oil pressure senders and the tachometer input for the DeStroked tachometer adapter (more on that in a bit). There are many ways to modify the harness and a strong working knowledge of electrical wiring is mandatory. Access to Ford and Dodge schematic diagrams is also a must. There are also a number of wiring mods that need to be done to the Ford and Dodge harnesses in order to make the air conditioning, fan clutch, and cruise control function. The folks over at DeStroked helped by providing wiring schematics that addressed some of the modifications needed. An item of note: The Dodge PCM had to be reflashed as a manual transmission-equipped vehicle in order for the engine to run correctly.

PhotosView SlideshowThe Bottom Line

As you can see, there are a number of challenges to a swap like this. Ultimately, though, the aftermarket offers the main hard parts to help get the job done. Even so, when installing a computer-controlled diesel engine into a late-model rig you'll need a firm grasp of electronics in addition to general wrenching and fabricating experience. You'll also need patience and time. The payoff? You'll have a unique rig that combines your favorite truck with your favorite diesel engine.

The Cost

So what does a swap like this cost? We asked Zuccarello to keep a tally of his out-of-pocket expenses for hard parts. Keep in mind that this reflects his specific expenses for this specific swap.