Alan Huber

Art Director

Photographers:

Cody Huber

Alan Huber

Art Director

Photographers:

Cody Huber

Like a mom always reminding her kids to brush their teeth or wash behind their ears, someone is always chastising wheelers about the safety of their rigs. We don't like hearing it, yet we know it's a good idea. Although as wheelers we may take additional chances with our 4x4s off-road, we don't want our vehicles to be the cause of any harm to others through poor engineering, right? Right! You've made Mom proud.

Here's what's in the A118 kit: (1) Dust shields, (2) rotors (slotting and zinc-plating are optional), (3) wheel spacers, (4) cast-iron calipers with integral parking brakes, (5) caliper mounting brackets, (6) adapter brackets, (7) brake hoses, (8) mounting spacers, (9) parking-brake cable brackets, (10) banjo bolts and blocks, (11) mounting-bracket bolts and nuts, (12) caliper mounting bolts, (13) reducing rings, (14) parking-brake cable clevis, (15) crush washers, (16) cotter keys, and (17) clevis pins.

One of the most mundane, yet important, areas of safety is the brakes. If you're now running around on tires as tall as some cars, the trickle-down effect takes over. The big tires are probably double (or more!) the weight of the originals. Stronger axles to handle those big tires also add weight. The suspension lift to fit those tires affects weight transfer by raising the truck's center of gravity. And then there's the performance hit created by the added leverage of tall tires. Factory brakes get overwhelmed.

The drum brakes used on many OEM vehicles are simple and satisfactory for stock trucks, but if you're building a high-performance 4x4, then don't forget high-performance brakes. Stainless Steel Brake Corporation. (SSBC) has all sorts of rear disc-brake conversion kits to fit virtually any 4x4's rear axle. We ordered one for a 9-inch Ford truck axle (PN A118), but many of these steps are similar to other SSBC kits. If you aren't comfortable working at home on a system as important as brakes, a reputable shop can easily handle the install for you.

The SSBC kit is designed to work with the vehicle's stock proportioning valve arrangement, but you may want to fine tune your front-to-rear brake bias by adding an aftermarket adjustable proportioning valve. Brakes stop best when adjusted so the front wheels lock up a fraction of a second before the rears. There are many brands and styles of adjustable valves to choose from, but all are installed in the rear brake line and reduce the amount of fluid pressure going to the rear brakes. Many late-model vehicles have a combination valve that handles rear brake proportioning along with several other brake functions such as serving as a mounting point for warning light switches, bleeder valves, and metering valves and serving as junction blocks. Combination valves must be modified before using an aftermarket adjustable valve. We modified a late '70s Ford combination valve for this story. Other makes may look the same, but function differently, so get a repair or service manual to figure out how yours operates and what needs to be changed.

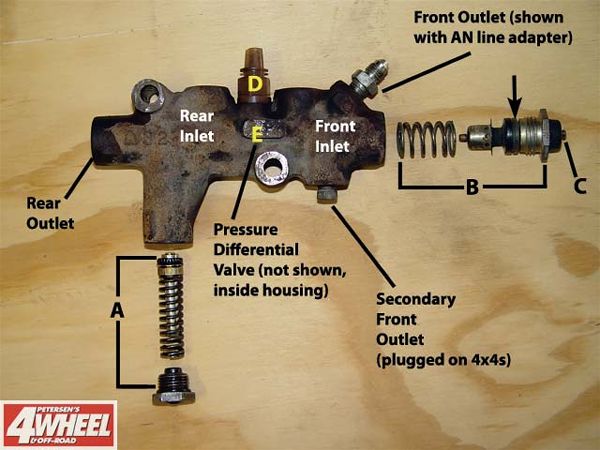

A- Proportioning Valve: Reduces fluid pressure to rear brakes

B- Metering Valve: Holds off pressure to front discs until slower rear drums can react

C- Bleeder Rod: Must be pulled out when bleeding factory brakes

D- Brake Light Warning Switch

E- Pressure Differential Valve: Senses pressure imbalance

Here is a combination valve out of a late-'70s Ford with the major parts labeled. If you're adding an aftermarket adjustable proportioning valve along with rear disc brakes, the factory valve must be modified as outlined here. The factory proportioning valve (A) must be gutted by removing its internal spring. There is also a metering valve at the front (B) that balances disc/drum system actuation by holding off pressure to the front discs until the rear drums catch up. Remove the small washer (arrow) near the middle of the valve to disable it. From the factory, the bleeder rod (C) must be held out by a special clip when bleeding the system. This will no longer be necessary once the metering valve has been modified. Many people may want to ditch the entire valve, which is fine, but then the brake warning light switch (D) will no longer operate unless it is relocated. Note also how the combination valve serves as a handy junction block for the four brake lines. The pressure differential valve (E) senses any hydraulic pressure imbalances between the front and rear brakes and alerts the driver with the brake warning light. This valve is not modified, but be sure to mount adjustable proportioning valves downstream of this valve or your warning light will stay on permanently.