In the past we have had air lockers, but weren’t always crazy about them for a couple of reasons: having to wait for air pressure to build for locker engagement and having to listen to a compressor became tedious. It may not seem like much of an issue to some, but when you want or need the air lockers engaged or unengaged quickly and positively, waiting is not an option.

In our arsenal of equipment we take on our regular outings is a 15-pound CO2 bottle from Powertank, and we have grown to appreciate how quickly we can fill a set of 42-inch tires. There is also no air compressor rattle to listen to, and this prompted us to consider the same CO2 system to work the new selectable lockers on our Jeep Wrangler.

Powertank offers a couple of options designed to work as the air supply for lockers, the JET PAK 2 and the JET PAK 3-Pro Series. Many competitive drivers are using these systems for the same reasons we were considering it. By eliminating the compressor there is one less component that can fail, and engagement is quiet and nearly instantaneous.

The installation of the 3-Pro Series set up was pretty cut and dry. The air lines for the front and rear lockers were routed in a protected manner to keep them free from anything that may cause damage while out wheeling, and we made sure to leave enough line to allow for full axle droop. The toggle switches are marked for ease of installation: The “In” port is for the supply line from the JET PAK, and the “Out” port goes to the locker itself. There are also a couple of additional ports: one for “Exhaust” and the other is a jumper from one switch to the other. The jumper was used to supply the second switch with CO2 because we planned to run front and rear lockers.

The JET PAK 3-PRO Series system comes with the Sidearm Regulator designed to handle up to 300 psi, and the company’s literature claims the system will engage a locker hundreds of time using just a single 20-ounce bottle. We decided to engage the lockers multiple times to see if we could in fact get “hundreds” of actuations out of a single bottle.

First we measured the weight of our bottle. The 20-ounce JET PAK bottle weighed 1 pound, 14 ounces empty. Full of CO2, it weighed slightly more than 3 pounds, 1 ounce. We then actuated the front and rear lockers separately, 100 times each. Some of the CO2 was used during our installation to ensure things were working before we started our testing, but at the very least this would show that we could get even more than the planned 200 operations. With the installation and test completed, we weighed the bottle again. It weighed 2 pounds, 10 ounces, so we had used roughly 7 ounces of CO2 during more than 200 operations, lending credibility to the claim of being able to get “hundreds” of uses from a single bottle.

Here are a couple of installation tips worth sharing: It’s a great idea to plan ahead and allow enough space for the air lines that connect to the switches. They took up more space than we originally figured, so we wound up fabricating a second mounting bracket to allow for enough protected room. Secondly, when mounting the bottle, it’s best to mount it in an upright position. This will minimize the chances of the liquid CO2 accidentally getting sprayed into the lines and freezing them, causing damage or failure.

The complete Powertank JetPack system is small enough to easily mount in a variety of locations and with a number of different mounting options.

The complete Powertank JetPack system is small enough to easily mount in a variety of locations and with a number of different mounting options.

There is a storage bag with the kit to keep the extra bottle safe and protected until it’s ready for use.

There is a storage bag with the kit to keep the extra bottle safe and protected until it’s ready for use.

One of the most popular (and the one we used) options is the rollcage or bar mounting bracket included in the kit.

One of the most popular (and the one we used) options is the rollcage or bar mounting bracket included in the kit.

The Powertank air line easily connects to the air locker through the axle’s differential housing.

The Powertank air line easily connects to the air locker through the axle’s differential housing.

Because this particular Jeep YJ Wrangler we were mounting the Powertank Jet Pak in was a half-cab, we chose to place it on the vertical bar behind the driver seat for easy access. It’s best to mount the air bottle in as upright a position as possible for optimal operation.

Because this particular Jeep YJ Wrangler we were mounting the Powertank Jet Pak in was a half-cab, we chose to place it on the vertical bar behind the driver seat for easy access. It’s best to mount the air bottle in as upright a position as possible for optimal operation.

The Jeep’s underbody provided a protected and easily accessible route for running the air line along.

The Jeep’s underbody provided a protected and easily accessible route for running the air line along.

It’s a good idea to tape the ends of the air line while routing it to make sure no foreign objects get inside the line and create an obstruction.

It’s a good idea to tape the ends of the air line while routing it to make sure no foreign objects get inside the line and create an obstruction.

Be sure to leave enough extra air line in the installation to account for full droop of the axles.

Be sure to leave enough extra air line in the installation to account for full droop of the axles.

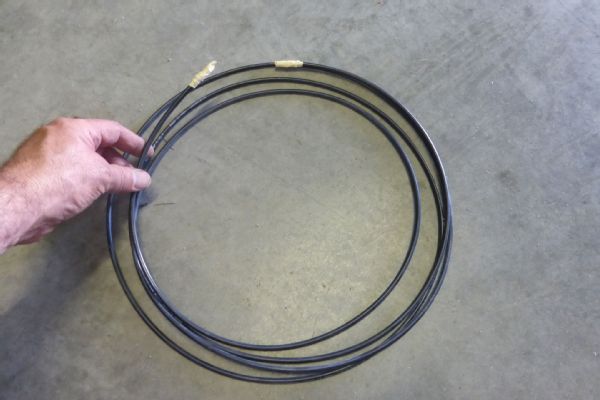

Prior to installation, it’s a good idea to check over all the air lines for any deformities or damage that may affect the flow of air to the lockers.

Prior to installation, it’s a good idea to check over all the air lines for any deformities or damage that may affect the flow of air to the lockers.

Because this section of air line was strung through the engine compartment we covered it with a length of rubber hose for extra protection.

Because this section of air line was strung through the engine compartment we covered it with a length of rubber hose for extra protection.

It’s best to mount the air bottle in as upright a position as possible for optimal operation.

It’s best to mount the air bottle in as upright a position as possible for optimal operation.

We fabricated a custom bracket to mount up the toggle switches that control the airflow to the air lockers in the front and rear axles.

We fabricated a custom bracket to mount up the toggle switches that control the airflow to the air lockers in the front and rear axles.

With the 20-ounce air bottle completely filled and ready for operation, it weighed just a little more than 3 pounds.

With the 20-ounce air bottle completely filled and ready for operation, it weighed just a little more than 3 pounds.