Ali Mansour

Brand Manager, 4WD & Sport Utility

Ali Mansour

Brand Manager, 4WD & Sport Utility

Building A Custom Axle isn't all about saving time and money, but about creating the perfect axle for your needs and building something that will last more than a week or a year-one that will last a lifetime.

Aftermarket axles are the way of the future. Taking 30-year-old technology and combining it with modern day components gives you 1-ton brute strength that allows you to beat mercilessly on your rig. and although buying a custom axle is an intimidating and oftentimes expensive decision to make, it may be the last axle you ever need to buy.

So why build a custom axle instead of a junkyard jewel? as our appetite for more powerful and bulletproof drivetrains increases, so rises the demand for highpinion Dana 60 axles. What once was as simple as driving down to your local wrecking yard has now become more like searching for the Holy grail. It's the old supply-and-demand principles, and though we always hear about somebody's buddy scoring one for 200 bucks, when its time to find that same "buddy" deal, the price seems to climb closer to $1,200.

Though a couple of grand is still a fraction of what many of the complete aftermarket units cost, unless you're a master fabricator and axle technician, you may be stuck with the factory axle dimensions, causing the vehicle to fit the axle, instead of creating an axle to fit the vehicle.

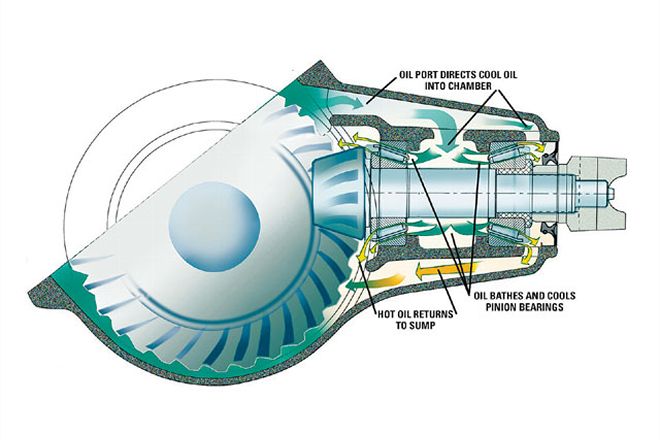

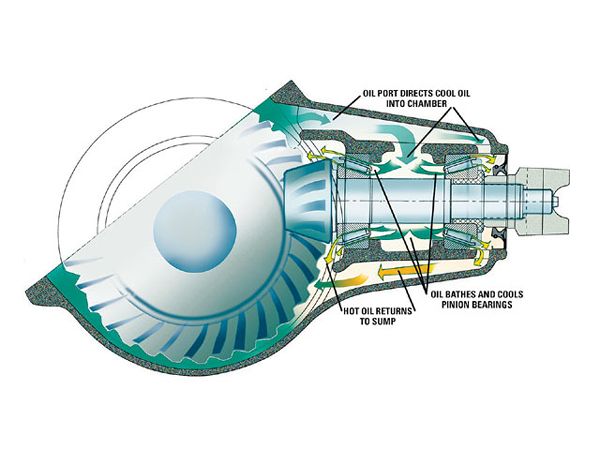

Having taken a few previously recorded measurements to determine pinion angle, axle width, and caster for a specific vehicle, our goal was to build the ultimate mini-truck front axle. To help with the build we took a trip over to Currie Enterprises to create a custom RockJock III 60 with one of the axle legends himself, John Currie. seeing as how most minitruck (Ranger, s-10, Dakota, and Tacoma) straight-axle conversions require a highpinion driver-side-drop front axle, the RockJock III made the most sense both economically and buildwise. The 3-inch axletubes combined with the beefy centersection allow you to run anything from radius arms to leaf springs without stressing or damaging the axle, and the fresh steel makes it extremely fabricator friendly. Though we recognize that custom axles are not for everybody-especially considering that some of us may never even reach the performance potential of what the factory provides us with-there are those of us that destroy those drivetrain components on a weekly basis.