Mountains of Northern Mexico: "Service Engine Soon," said the dash warning light. Oil pressure seemed OK, as did engine temperature and alternator output. Check under the hood: Fluids, hoses, serpentine belt, and maintenance-free battery all OK. Check under the truck: Nothing leaking, nothing dangling.

We headed for the States. By the time we crossed the border and reached the nearest shop that could read the code, the tach was showing 4,000 rpm to maintain 40 mph.

The tech plugged into our Tahoe's computer. "The readout says your transmission is slipping." We didn't need a computer to tell us that.

"How many miles you got on this Tahoe?"

"Odometer says 140,000."

"Well, you didn't do too bad. A lot fail before that, though. We can't overhaul it. We could install a factory overhaul. Probably take a week or so to get it here, plus two days to install. We don't do many of these."

We checked the nearest transmission shop's reputation, called ahead and had our Tahoe hauled on a flatbed 250 miles to Odessa Transmission in Odessa, Texas.

"OK, we got the same transmission as yours, GM's 4L60-E, in stock and could have you out of here by noon tomorrow.

"Or, we could overhaul yours. Take an extra day." Kind of interesting. We decided to have Odessa Transmission overhaul ours.

The next day, our Tahoe was on the lift, and the transmission was on its way out of our 4x4. The overhaul would be done by Steve Beckworth, one of the several brothers operating Odessa Transmission, a family-owned business founded by Earl Beckworth, the brothers' father, in 1956.

We can tell you something right now: This automatic transmission will never work. Look, our Tahoe's transmission has:

* 73 external components

* 65 internal components

* 23 oil seal locations

* 39 internal oil-pump assembly parts

How can this ever work?

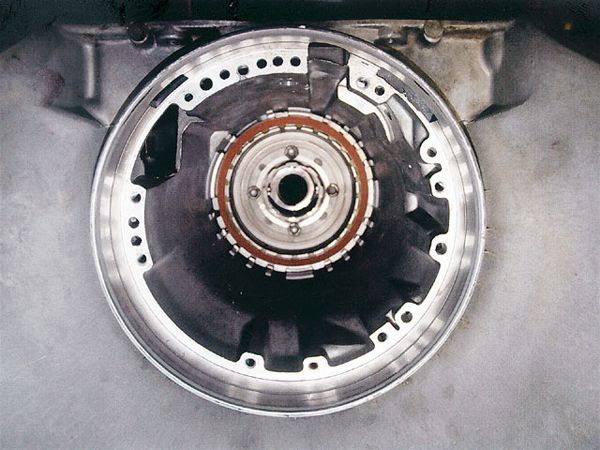

The brick-red friction clutch surface is but one of 26 components fitted vertically in GM's 4L60-E automatic transmission; each component must act perfectly with units above and below.

The brick-red friction clutch surface is but one of 26 components fitted vertically in GM's 4L60-E automatic transmission; each component must act perfectly with units above and below.

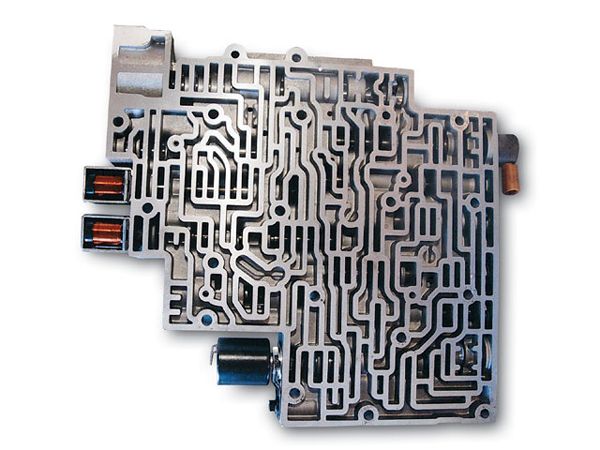

Our Tahoe's valve-body maze of transmission fluid channels has 20 bolts to be set and torqued in sequence, as well as seven valves, six solenoids, two oil screens, and one transmission-fluid valve-all of which have to work together in concert in an environment where malfunction of any one component can bring about a cascade of failures requiring a complete overhaul. For that reason alone, we recommend leaving this job to the experts.

On a straightforward overhaul, every part coming out has to be meticulously inspected for contributory causes of failure. Every worn part is replaced with parts that are brand-new, out-of-the-box, inspected, measured, carefully installed, and initially lubricated using a Vaseline-like lubricant that turns to transmission fluid when heated.

As much as component fit and compatibility will allow, each transmission is updated as closely as possible to the current year. Our 1998 4L60-E became a "2006" 4L60-E.

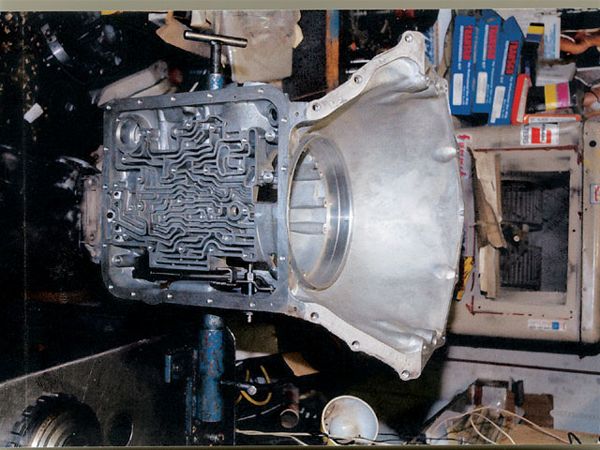

Ready for rebuild, the transmission housing is secured in a mount that can be rotated 90 degrees for horizontal work on its multichannel valve body.

Ready for rebuild, the transmission housing is secured in a mount that can be rotated 90 degrees for horizontal work on its multichannel valve body.

But what about modifications for drag-racing, four-wheeling, and towing? There are two ways to do that. Some aftermarket transmission parts sources such as TransGo produce reprogramming kits and shift kits that a transmission tech can install. Or a transmission tech who is as much an artist as a technician can combine several reprogramming and shift-kit parts with OEM parts he's modified to produce a hillclimber and mud-bogger seldom seen. There are also reprogramming kits to modify many transmissions for "heavy duty" (read: towing) and "competition" (read: drag racing). With a competition reprogram, you can expect greatly reduced gas mileage. At the other end of the spectrum, a skilled transmission tech can modify your transmission during overhaul for increased gas mileage, which when combined with a "fuel-maximizer" torque converter, is said to be able to increase gas mileage up to 15 percent.

With the feds pressing OE manufacturers for ever-increasing fuel economy, the manufacturers have taken many transmissions as far as they can, so your truck's tranny may have already been fuel-economized to its max. In a bid to further boost fuel economy, OEMs have six-speed automatics in the pipeline, and Lexus has already introduced an eight-speed juicebox on the LS460 sedan.

Your 4x4 isn't going anywhere without a torque converter between its engine, flywheel, and automatic transmission.

Exacting design and placement of vanes and blades in a converter's turbine, all lubricated by the transmission's fluid, combine to double engine torque. Engine rpm in and rpm out to the transmission are unchanged. The stator "floats" between the turbine and impeller.

Exacting design and placement of vanes and blades in a converter's turbine, all lubricated by the transmission's fluid, combine to double engine torque. Engine rpm in and rpm out to the transmission are unchanged. The stator "floats" between the turbine and impeller.

A typical fullsize truck torque converter-a 12-inch-diameter, 6-inch-thick, 33-pound lubricated component-utilizes precisely vaned and bladed impellers, stators, and thrust turbines (plus a little magic) to double the torque produced by your engine's driveshaft.

For optimum performance for your trail driving, your engine, torque converter, and transmission need to form a coordinated team. Your transmission tech, probably after talking with technical advisers at a transmission overhauler and torque-converter manufacturer, can make the match.

There are a range of torque-converter modifications, to include various stall speeds, to match your engine/transmission combo. For demanding off-pavement use, Don Randolph of torque-converter builder Daaco in Cookesville, Tennessee, can provide your transmission shop with a converter that is "indestructible."Torque converters can have weaknesses that can sometimes result in catastrophic failure, "killing" the converter. In our case, our torque converter's turbine and stator race showed signs of cracking when they were removed. Fortunately, these cracks were found at converter overhaul-before failure.

As has been said before, heat is a destroyer of transmissions. To increase the tranny's reliability and lifespan, keep it cool.

An operating temperature of 175 degrees Fahrenheit is considered nondetrimental to your transmission fluid. Operating temperatures above that will damage fluid and harden seals, causing internal leaks that shorten the life of your tranny. According to technicians at Lubegard International:

Internal temps of 200 to 240 degrees cause oxidation and thickening of fluid; at 240 to 250, varnish begins to form and additives are cooked out; and from 260 to 300, fluid degrades to the point where clutches slip, being virtually unable to move your truck.

Your tranny's multi-channel valve body contains a number of ball bearing-like valves that need to move freely at various shift points. Thickened transmission fluid can deprive your radiator, and its closely mounted OE transmission-fluid cooler, of airflow they need.

An electronic transmission valve body is distinguished by the two copper coils at left; a non-electronic transmission's valve body has no copper coils.

An electronic transmission valve body is distinguished by the two copper coils at left; a non-electronic transmission's valve body has no copper coils.

An auxiliary transmission cooler such as NAPA's Ultra-Cool (PN 4822) mounted on the front of our Tahoe's radiator has lowered our tranny's operating temperature by 50 degrees. Cooler cost was $49.99, plus one-hour installation.

TransGo offers two transmission reprogramming kits, one for vehicles under 5,000 pounds, and one for vehicles over 5,000 pounds, which TransGo says can "increase gas mileage and easily double the life of a transmission."

Beyond the above, check your transmission fluid whenever you check your engine oil, making sure to follow your owner's manual for fluid level check and addition of fluid.

Finally, your transmission filter should be checked and fresh fluid added about every 50,000 miles or as per the manufacturer's recommendations.

So what did it cost us? And what would we have paid to have a dealer do the work? A Chevy dealer bid for a "transmission overhauled for General Motors" was $2,624 installed with a rebuilt torque converter; the work was warrantied for 100,000 miles or 36 months, whichever comes first.

By contrast, our Odessa rebuild totaled $1,577 installed, with rebuilt torque converter, warrantied for 6,000 miles or six months. We're way beyond those figures already.