One of the best things about working in the magazine business is the opportunity extended by manufacturers to let our lenses behind closed doors to document precisely how a particular product is made. With this series, we have covered a whole assortment of topics ranging from complete vehicles to the tires they roll on. However, until now, cast aluminum wheels have gone overlooked, so we jumped at the opportunity to tour the manufacturing facility of American Eagle Wheels, located in South Carolina. While some of the various steps in the manufacturing process were off-limits to our lenses, we were able to see for ourselves most of the steps involved in how a cast aluminum wheel is made. We left with a newfound respect for the efforts required to build them.

We see cast aluminum wheels every day, but rarely does anyone ever know what actually happened behind the scenes to produce them. The process is laden with highly sophisticated equipment and materials that combine to create high-strength, perfectly round parts for your ride. This pallet of raw castings represents the halfway point in the manufacturing process.

We see cast aluminum wheels every day, but rarely does anyone ever know what actually happened behind the scenes to produce them. The process is laden with highly sophisticated equipment and materials that combine to create high-strength, perfectly round parts for your ride. This pallet of raw castings represents the halfway point in the manufacturing process.

More About American Eagle Wheel

Founded 1977, American Eagle is a family owned and operated manufacturer. The American Eagle family of brands includes the following: MSR/BOSS Motorsports, Eagle Alloys, Vodoo, Extreme Alloys, and USA Forged.

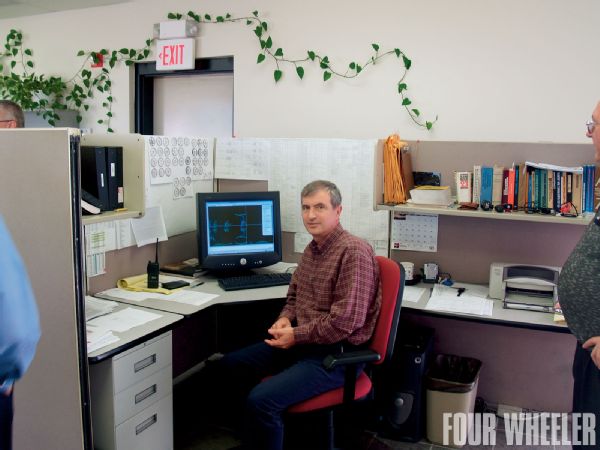

Each wheel begins life as an idea that is digitized by a talented designer and CAD software. Here, lead Mechanical Engineer Bob Arsov pauses from his latest design to explain how his visual concepts undergo stress test analysis in virtual form prior to development. Once a design passes critical strength evaluations, a mold can be produced from that design.

Each wheel begins life as an idea that is digitized by a talented designer and CAD software. Here, lead Mechanical Engineer Bob Arsov pauses from his latest design to explain how his visual concepts undergo stress test analysis in virtual form prior to development. Once a design passes critical strength evaluations, a mold can be produced from that design.

Unlike most American-based wheel manufacturers, American Eagle operates entirely on U.S. soil. All wheels start from raw material that originates within the USA, and all manufacturing processes take place here, too. All other wheel manufacturers have moved all or part of their processes overseas to take advantage of export subsidies, devalued currencies, as well as environmental and labor cost savings. At the time of print, American Eagle was the only remaining aftermarket producer of cast aluminum wheels that can truthfully claim "made in the USA."

PhotosView Slideshow