It's always great to watch a pro do his work. Maybe it's an extreme motorcycle jumper, maybe a guy who carves tree trunks with a chain saw, or even a World Rally Championship driver work the switchbacks on a mountain trail.

It's the same in the hot rod world: watching an expert painter lay down some insane graphics or an upholstery guy doing a one-piece headliner in a sedan. Then there are those who weld.

If you've never heard the term "stacking dimes," go look at the TIG weld on some stainless steel and, if it looks like the edge of a $5 stack of dimes laid over at a 45-degree angle, then whoever welded that tubing has "the gift."

But making pretty welds isn't as important as making good welds—something Matt Bryant certainly knows firsthand. At 47 years old, Bryant has been the "go-to" guy for race shops and suspension manufacturers all of his adult life in and around the Inland Empire region of Southern California.

Having done design and fabrication work for Porsche of America and Yamaha's Road Race team, plus welding full time for motorcycle manufacturers C&J Racing Frames as well as hot rodder's Foothill Fabrications and Walden's Speed Shop, Bryant knows his way around a welding machine, and can capably weld anything you can give him.

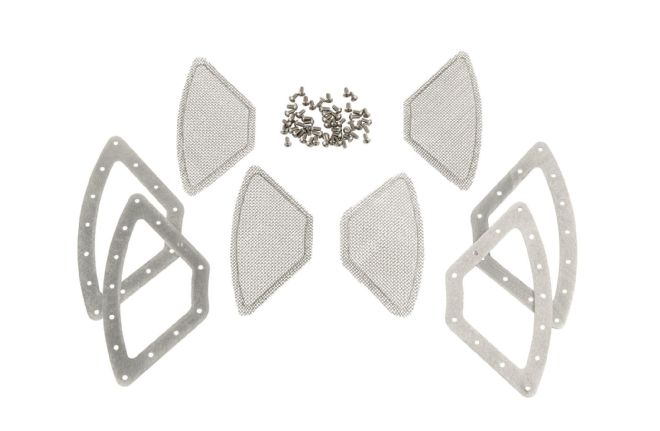

The basic kit from Haze City Specialties gives you the flanges, screens, and enough mini screws to attach them to your backing plates.

The basic kit from Haze City Specialties gives you the flanges, screens, and enough mini screws to attach them to your backing plates.

Eight years ago, in order to have a creative outlet for his talents, Bryant formed Haze City Specialties, then moved to Corona, California, where he set up shop, working on customer projects as well as developing his own line of products.

Among the first of those items are a handful of vent kits for vintage brake backing plates, which not only provide extra cooling for a brake system, but they dress them up pretty nice, too. Haze City Specialties fabricates and sells kits for a standard-type '39-40 Ford backing plate, but also kits for Deuce Manufacturing's Functional Fake aluminum backing plates as well as MT Car Products' reproduction Lincoln backing plate.

The kits come with everything you need to do the work in your home garage, including the four screens (in natural stainless steel or brass), flanges to hold the screen in place, and more than enough screws (button head Allen or Phillips) to secure the flanges to the backing plates. Haze City Specialties can also supply all the necessary backing plate hardware (in stainless steel, no less) for the '39-40 backing plates and offers another kit containing a #43 drill bit and 4-40 tap if you don't have the right ones in your toolbox.

If you don't want to do the work, you can send them to Bryant and he'll do them for you, but if you follow the photos and instructions here you shouldn't have any problem doing the job yourself.

1. Arguably the most popular backing plate used in rodding today, the '39-40 Ford backing plate (for use with round spindles) is the base for the vent kit. The kit does not fit a '41-type backing plate (with square-shaped spindles).

2. Upon inspection, the raised section of the backing plate is 1/8-inch longer along its vertical edge versus its horizontal edge.

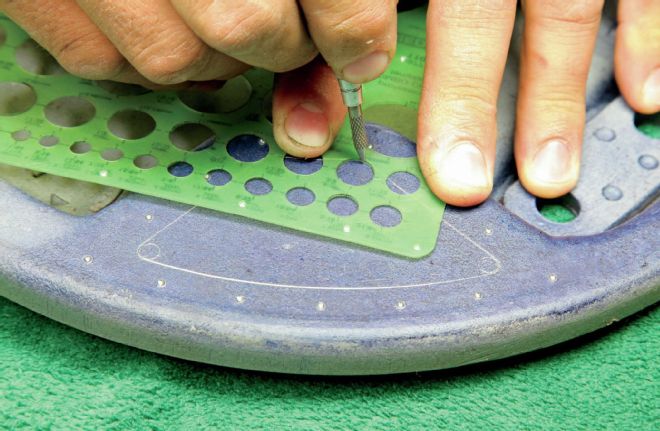

3. After using Dykem Layout Fluid, which provides a thin film that can be scribed, the kit's flange is centered on the backing plate, clamped, its inside edge scribed, as well as the mounting hole location.

4. A center punch is used to mark the location of the mounting holes.

5. Using a circle guide, the rounded corners of the vent holes are then scribed. The circles used nearer the spindles are 1/2 inch (with a 1/4-inch radius for the corner) while the 3/16-inch circles on the outside edge. A center punch to mark the centers of all four circles should be used, too.

6. The backing plate should look like this when fully scribed.

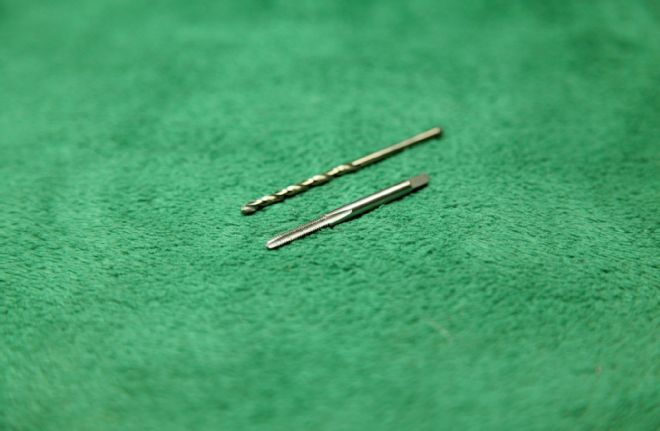

7. In case you don't own a full selection of drill and taps, Haze City offers a mini kit with both items.

8. Though it can be done with a handheld drill, using a low-speed drill press makes it easy to drill each of the flange holes.

9. With a handheld drill, the flange mounting holes are tapped.

10. With all the mounting and corner holes drilled, the backing plate should look like this.

11. A cut-off wheel is used to cut the sections between the corner holes.

12. A grinding wheel is used in the corners to finish up the vent hole.

13. The kit's screen fits behind the flange.

14. And the screws are used to secure it to the backing plate.

15. Haze City also offers a new stainless steel hardware kit for the backing plates, too.

16. This is a finished '39-40 backing plate when finished out with the Haze City Vent Kit and their stainless steel hardware kit.

17. Haze City also manufactures a Vent Kit for Deuce Manufacturing's Functional Fake aluminum backing plates, used with Deuce Manufacturing's forward-facing air scoops.

18. Vent kits can also be ordered with brass screws and screens for a totally different look.

19. Haze City Vent Kits are also made to fit MT Car Products' Lincoln-style brake backing plates.