We ask a lot of our classic Chevys. Sometimes, way more than the parts, designed nearly 50 years ago, can handle. This is especially true of the suspension. Modern cars have modern handling and we’ve come to expect this level of performance from our classics, as well. And, while a ton can be done to upgrade a suspension built around a stock subframe, it’s still limited by its original design. Enter the aftermarket.

At some point suspension companies figured out that it would be advantageous to just ditch the whole OE subframe and design something better using modern materials, manufacturing techniques, and with increased performance in mind. The stock subframe in a 1967 Camaro was never designed for high-performance handling, but the aftermarket subframes being sold today had performance built in the equation from the get-go.

Art Morrison Enterprises (AME) saw the limitations of the stock subframe and, after listening to their customers, designed a subframe that would give our classics modern handling and performance capabilities. We asked their lead engineer, Matt Jones, to go over some of the technical highlights.

As Matt explained, “Antidive is set to minimize nose-dive during hard braking without resorting to higher spring rates, giving a more comfortable ride and safer braking. However, it isn’t so high that bind results when braking during a turn. We also shot for a caster setting of 5.5 degrees for stable highway manners and positive steering feel where it still maintains a crisp turn-in, but the caster can be taken as high as 7 degrees if needed.” He also stated that they spent a lot of time dialing in the right amount of camber gain. The goal was to have enough for track duty, but no so much that it would cause unnecessary camber thrust in bump. In addition, AME worked to minimized camber gain during braking so that more of the tire’s footprint would stay planted to the asphalt, which yields shorter stopping distances.

Another design change—bringing in the ’rails 2 inches—allows the frame to accept the wider front tires favored by today’s gearheads. In terms of suspension components, AME chose to go with parts from the newest generations of Chevrolet’s Corvette. Why? Simple, they had the right geometry, were track proven, lightweight, and would make it simple for their customers to find replacement parts just about anywhere. Starting from a clean slate also let AME easily add modern rack-and-pinion steering without having to make suspension geometry compromises. The result is a subframe system that lets you easily inject 21st century handling into your 1960s era Chevy.

To get a closer look at one of their subframes we headed over to Best of Show Coach Works to check out one getting slid under Mike Sevagio’s 1967 Camaro RS. Mike’s goal is to have a classic Camaro that drives and handles like a modern sports car, so updating the suspension was high on his list of “must dos.”

01. According to Matt Jones, Lead Mechanical Engineer at Art Morrison Enterprises (AME), “the framerails are mandrel bent to ensure proper wall thickness using materials that are only available to AME. When fully assembled the subframe is about 50 pounds lighter than stock.”

02. AME offers a variety of transmission crossmembers to fit most any modern transmission. In this case it’s to accommodate a Tremec Magnum six-speed. You can also spot how AME incorporated exhaust passageways to allow tubing to be tucked up into the frame instead of hanging below the framerails.

03. Instead of offering an old, and increasingly hard to find, rebuilt steering rack, AME supplied a much nicer 20:1 ratio Detroit Speed rack. Custom-tuned Woodward steering racks are also available as an option.

04. The AME subframe uses the same LS-engine adapter plates common to most aftermarket subframes. To this billet piece you just need to add a pair of Energy Suspension’s small-block urethane mounts (PN 1114G).

05. Before tearing down the subframe for powdercoating, we decided to mock it up under our 1967 Camaro with a plastic LS fitment engine. Everything fit well, but many of the aftermarket headers we tried didn’t clear or caused steering shaft issues. Our fix was to order up a set of Art Morrison LS headers made specifically to work with this subframe.

06. After having the subframe powdercoated in one of the 50 shades of gray offered by Embee Performance Coatings, we began installing all of the parts, starting with the power steering rack.

07. We were pretty surprised when the subframe showed up wearing C7 lower control arms instead of the C6 versions we were expecting. AME chose to go this route since the C7 pieces reduce unsprung weight by 2 pounds compared to C6 arms.

08. Using the supplied fasteners, we installed the lower control arms (LCA). The threaded bosses in the LCA and steering rack are manufactured using a unique process that produces stronger rolled threads instead of the more common cut type.

09. Double-shear brackets are welded in place for the lower control arms to ensure proper strength in all situations. They also keep the bolts from walking out.

10. We then mated the C7 Corvette upper control arms (UCA) to the freshly powdercoated AME subframe. As for the aluminum spacers, Jones explained, “The aluminum spacers between the UCA and the bracket are machined at a constant thickness that provides a decent alignment to get the car to an alignment rack. We recommend the customer leaves them in there, gets it aligned, and then measures the total thickness of all the shims used for each bolt. At that point you can have spacers machined at that thickness for a clean look. You could also have a set made for a more aggressive track alignment. That way you can swap them out to easily; switch between street and track alignments.”

11. Bridging the gap between the upper and lower Corvette control arms is the job of a C6 Corvette knuckle. These are quite a bit stronger than the geometrically identical C5 knuckles and offer a huge number of OE and aftermarket brake options. Our build had standard C6 bearing packs, but for hard track duty you can order stronger ZR1 SKF bearings.

12. As Jones told us, “The AME-designed steering arm uses 8000-series chromium-moly steel (same material used for crankshafts and ring gears), which provides excellent strength while minimizing weight.”

13. AME offers several shock options, but the car’s owner decided to try a set of Viking Crusader double-adjustable shocks.

14. The lower end of the shock bolted in with a crossbar, just like a factory Corvette piece.

15. The upper eyelet of the Viking shock attached to the mount built into the AME subframe.

16. We could then install the supplied outer tie-rod ends to the rack and attach them to the steering arms.

17. Since this system uses a GM C6 Corvette steering knuckle the options for brakes are vast. If you’re on a tight budget then a set of pull-off Corvette brakes will bolt right up. We opted for a set of better looking, and performing, Wilwood binders. First up was installing the radial mount caliper bracket.

18. The 14-inch slotted and drilled two-piece rotor came in Wilwood’s proprietary E-coat. After a few hard stops the black coating will come off of the braking surface and stay everywhere else, resulting in a rotor that keeps looking great.

19. Rounding out our brakes was a pair of Wilwood Superlite 6 radial-mount calipers. The new FSL6R calipers ditched the external fluid crossover tubes and instead utilize two additional bleed screws, which gives them greater installation flexibility. The differential piston bores ensure even pad pressure and wear.

20. AME offers two sway bar options. For hard-core track use there’s a splined sway bar option with aluminum bushing housings. But for our street car we opted for the conventional type. The bar came will all the needed hardware, including steel bushing housings, urethane bushings, and retention clamp rings.

21. The 1 1/8-inch hollow sway bar had three positions for adjustments to roll rates of up to 10 percent. The endlinks were also fully adjustable for preload.

22. And here’s the finished passenger side. According to AME, the hub track is wider than stock to help nail a more ideal scrub radius, which in turn makes for excellent steering feedback and reduces steering system stress seen in racetrack use. You can easily run a 275mm wide tire without steering stops.

23. With both sides assembled, we could roll the subframe under our Camaro and bolt it in place. AME strengthened critical body mounting areas by using thicker materials, or additional bracing, to limit flex. The subframe had alignment holes to the get it close to square and then we measured to make sure it was perfectly square.

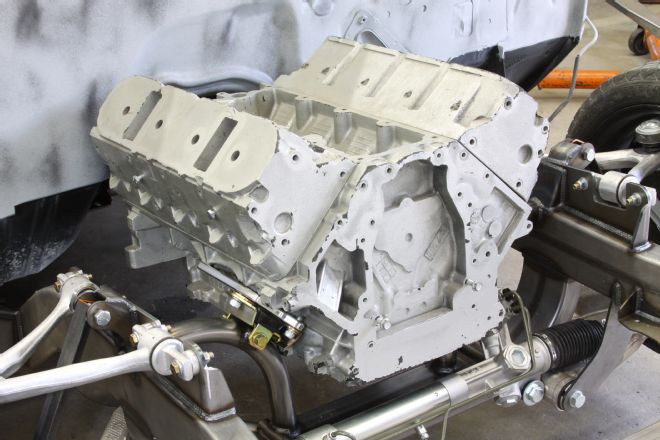

24. We then dropped our Chevrolet Performance LS3 crate engine in place. As expected from our previous test-fit with the plastic version, everything fit great and there was plenty of clearance in critical areas, like the oil pan to the rack and the back of the engine to the firewall.

25. Our stainless steel AME headers showed up and we had them thermal coated by Embee Performance in Santa Ana, California. The headers use investment cast flanges and short radius bends combined with 321 stainless 1 7/8-inch tubing. Best of all, they fit perfectly and made running a steering shaft from the rack to the column easy.