As the new year is upon us, it's time to do two things: come up with excuses why we've already abandoned most of our New Year's resolutions, and begin construction of the 2015 Road Tour car.

Although we have pushed the street rod envelope in the past, this time around we're reaching into the '60s and building a 1961 Ford Sunliner convertible. Our ragtop will be in the capable hands of Road Tour alumni, as chassis fabrication will be handled by the Roadster Shop (RS), and Hollywood Hot Rods (HHR) will take care of everything else.

One of the challenges of building '50s and later cars is the huge variation in chassis design from year to year, and in some cases model to model. To incorporate the modern suspension components, fat tires, and low ride height, we've come to expect in a contemporary street rod a new frame is often required and that was the challenge faced by the team at the Roadster Shop.

Neal Gerber, along with sons Phil and Jeremy, have made the Roadster Shop known far and wide for producing top-notch vehicles of all sorts and cutting-edge chassis and suspension components. Thanks to their in-house design, engineering, prototyping, and manufacturing capabilities, they can provide a custom chassis product that exceeds all expectations for virtually any vehicle.

This is what the 2015 Street Rodder Road Tour ragtop will look like when finished. The ’61 Ford Sunliner will ride on a new, state-of-the-art Roadster Shop chassis.

This is what the 2015 Street Rodder Road Tour ragtop will look like when finished. The ’61 Ford Sunliner will ride on a new, state-of-the-art Roadster Shop chassis.

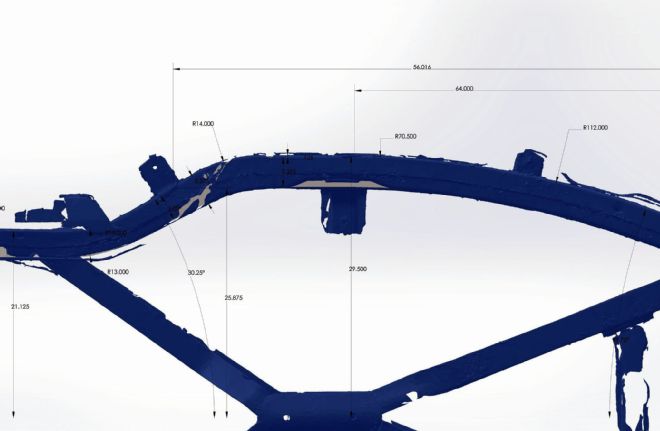

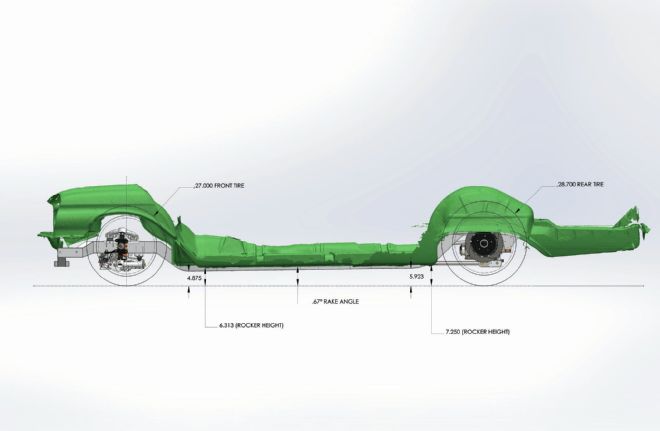

1. Here's a sneak peak of what will be under all that FoMoCo sheetmetal. The new frame mimics the shape of the original with only minor modifications to the truck floor required.

2. The original frame was bowed out to allow the floorpans to drop down. Note the husky X-member that was used to strengthen convertible frames.

3. To begin the scanning process the engine and transmission were removed and the body was lifted off the frame.

4. Looking like some sort of electronic suitcase, Exact Metrology used something called a Surphaser to scan the bottom of the body.

5. Despite being clean and in remarkable shape, the floorpan was sprayed with a compound that helped the scanner read the contours.

6. To reverse engineer the frame a Romer Absolute Arm was used to establish the contour of the framerails along with all the necessary measurements and mount locations.

7. All the information gathered by the Romer was downloaded into a CAD program.

8. With the dimensions of the original frame established and the contours of the floorpan known, the new frame can be designed.

9. Along with improved suspension, the design considerations for the new frame included tire size, ride height, and proper location of the wheels in the fender openings.

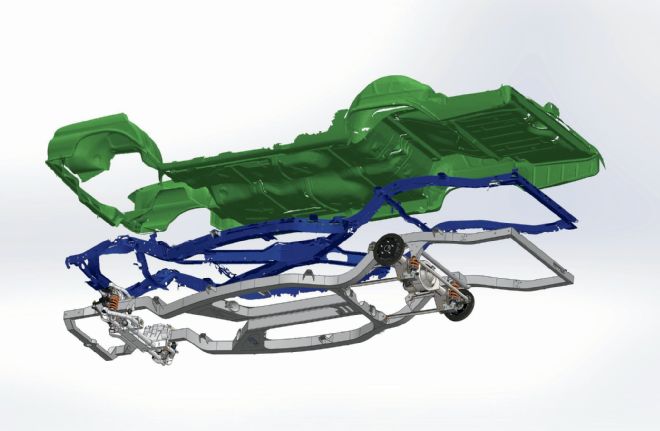

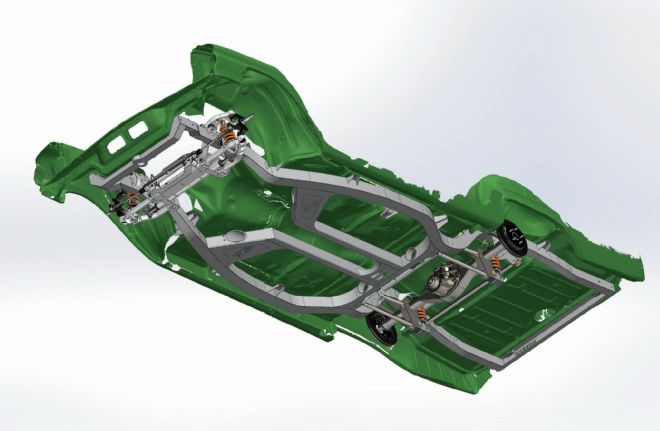

10. It doesn't get much more sophisticated than this: a CAD look at the bottom of the body, the original frame, and the new replacement.

11. A computerized test-fit of the new chassis eliminates the wasted time and effort of trial and error construction.

12. The new framerails are each fabricated from four pieces of Plasma cut cold-rolled steel. By using individual pieces complicated contours are easier to form.

The process of building a custom RS chassis for the first time, our Ford as an example, begins with what is often called reverse engineering. For that the Gerbers often call on the services of Exact Metrology, a company that uses various forms of 3-D scanning to create a CAD model where no model exists. Exact Metrology tells us their technologies will capture 3-D measurements from objects as small as a pinhead or as large as a nuclear power generation facility.

To determine the shape of the floorpan the frame is removed and a device called a Surphaser is used to scan the bottom of the body. Next an ultra-accurate measuring tool, a Romer Absolute Arm, is used to trace the frame and record its dimensions and the location of holes, brackets, and any other pertinent data required. Now comes the tricky part—a sophisticated computer program produces views of both that can be viewed separately or combined. That capability also allows a new chassis to be designed that fits the floor of the car with minimum modifications, has the general shape and mounting locations for the body found on the original frame while allowing the substitution of updated suspension components, lowered ride height, and precise location of the wheels in the fender openings.

Thanks to high-tech scanning equipment and state-of-the-art computer programs, along with the RS craftsmanship and expertise the 2015 STREET RODDER Road Tour Ford Sunliner is off to a great start—with more to come.

13. Each piece of the 'rail has registration marks that are aligned in the assembly jig. The numbers indicate the order in which the sections will be welded.

14. Once the 'rails are completely welded the edges are ground smooth. The result is they appear to be made from tubing.

15. With the 'rails in a dedicated assembly fixture they are leveled and squared before the crossmembers are installed.

16. First to go in place is the front crossmember—note how it is notched to fit the 'rails.

17. Next the rear crossmember is put in place. Note the notch for driveshaft clearance and a pair of tubes for the exhaust pipe to fit through.

18. The X-member is prefabricated and made up of two main sections. As in the rear, passages for the exhaust pipes are built in to keep them from hanging below the frame.

19. Clamped in place the legs of the X-member fit tightly to the framerails and rear crossmember.

20. With all measurements double-checked the X-member is TIG-welded in place. It's too bad all those beautiful beads will be out of sight.

21. Based on the scan of the original chassis all the new body mounts are positioned properly.

22. Here all the body mounts have been added along with a reinforcement plate at the back of the X-member.

23. The finished frame duplicates the shape of the original but is stronger, will have superior suspension, and the proper street rod stance.