Art Morrison Enterprises (AME) has developed a reputation building custom chassis for everything from Avantis to Zephyrs. By combining state-of-the-art manufacturing and design capabilities AME has given their customers exactly what they were after, a vintage looking vehicle with contemporary handling characteristics.

Fortunately for fans of custom classic trucks, the Morrisons, Art and son Craig, have applied their expertise to the haulers we hold dear—Craig's 1950 Chevy pickup was showcased in a two-part buildup that appeared in the December 2012 and the February, 2013 issue of Custom Classic Trucks. That exercise resulted in a truck that sits right, goes around corners like it's on rails, and stops on the proverbial dime. Thanks to the AME underpinnings this truck rides and handles like a contemporary sports car—it just begs to be driven as if it wants to prove what it's capable of.

While AME is known for complete chassis for cars and trucks (check out their website for a complete listing) they do offer front and rear clips along with suspension components for a variety of applications. Like everything they build, AME's suspension components are designed for those who value the driving experience and want a smooth ride and a great handling vehicle. The Morrison IFS features beefy control arms, adjustable coilover shock absorbers with urethane bushed mounts (air suspension is available for certain applications) and rack-and-pinion steering in either manual or power versions. For rear suspension systems, AME recently introduced their completely new IRS. Of course, their rugged four-bar components remain popular in standard and triangulated configurations.

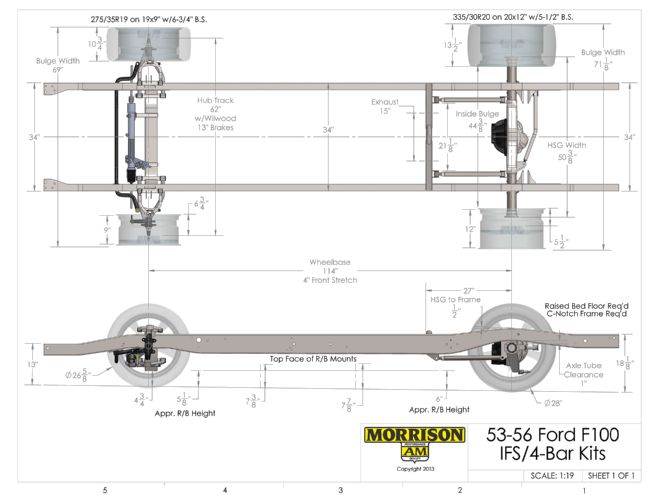

We like to drop in on the Morrisons whenever the opportunity presents itself because something interesting is always in the works. During our most recent visit we found a '56 Ford F-100 frame undergoing an update with the addition of an independent front suspension and a rear four-bar locating a 9-inch housing. Here's how they went about it.

1. Art Morrison stands behind his products, literally and figuratively. With son Craig and a talented staff of engineers, fabricators, and sales people AME has become a leader in the custom chassis business.

1. Art Morrison stands behind his products, literally and figuratively. With son Craig and a talented staff of engineers, fabricators, and sales people AME has become a leader in the custom chassis business.

2. As with the fabrication of new frames, the F-100 ’rails were attached to a super-stout steel table while modifications were made.

2. As with the fabrication of new frames, the F-100 ’rails were attached to a super-stout steel table while modifications were made.

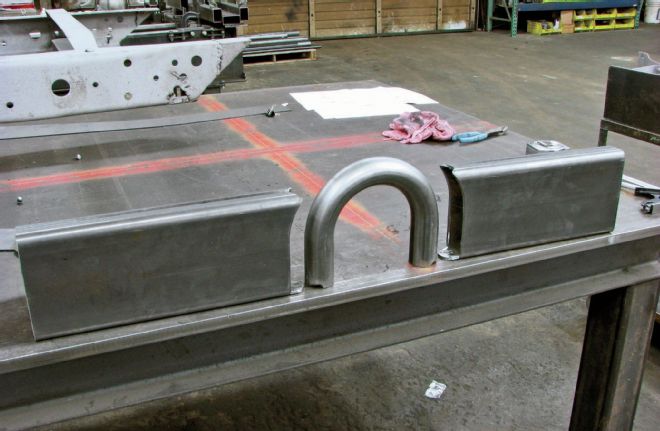

3. These are the components of the rear crossmember that will mount the four-bars. The hoop is for driveshaft clearance.

3. These are the components of the rear crossmember that will mount the four-bars. The hoop is for driveshaft clearance.

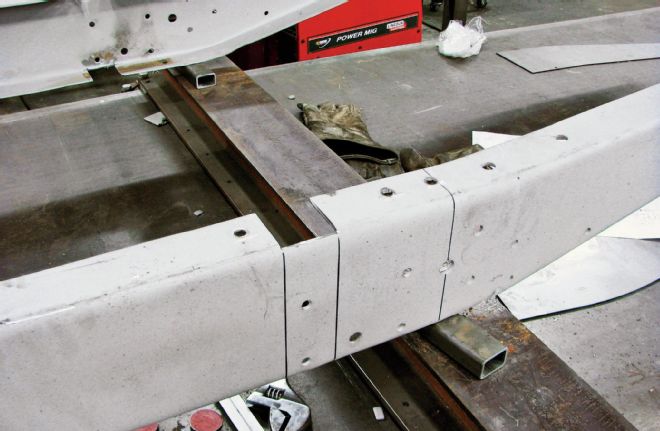

4. Notches are cut in the frame’s top flanges that allow the new crossmember to be dropped in place.

4. Notches are cut in the frame’s top flanges that allow the new crossmember to be dropped in place.

5. After making it flush with the top flange, the new crossmember is welded to the insides of the framerails.

5. After making it flush with the top flange, the new crossmember is welded to the insides of the framerails.

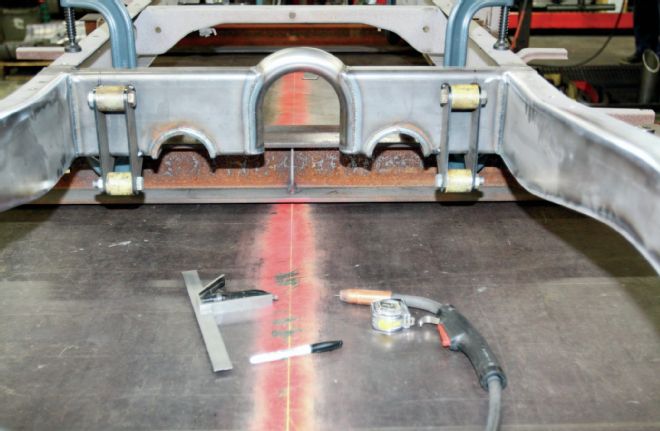

6. The crossmember has been welded to the framerails. Note the notches in the crossmember to allow the exhaust to be tucked up for increased ground clearance.

6. The crossmember has been welded to the framerails. Note the notches in the crossmember to allow the exhaust to be tucked up for increased ground clearance.

7. Boxing plates for the front framerails were precisely cut with a laser.

7. Boxing plates for the front framerails were precisely cut with a laser.

8. The boxing plates are cut to provide adequate area for a fillet weld that can be ground without compromising strength.

8. The boxing plates are cut to provide adequate area for a fillet weld that can be ground without compromising strength.

9. Once the welds are ground smooth, the boxed ’rails look like tubing.

9. Once the welds are ground smooth, the boxed ’rails look like tubing.

10. With the front crossmember clamped in place, Jacob Lusk checks and double-checks all the critical measurements before welding begins.

10. With the front crossmember clamped in place, Jacob Lusk checks and double-checks all the critical measurements before welding begins.

11. With the crossmember welded in place, this fixture is used to locate the upper A-arm mounting points.

11. With the crossmember welded in place, this fixture is used to locate the upper A-arm mounting points.

12. The upper control arm pivot and a gusset are attached to the fixture then tack welded in place.

12. The upper control arm pivot and a gusset are attached to the fixture then tack welded in place.

13. Here, the upper pivot gusset can be seen from the back.

13. Here, the upper pivot gusset can be seen from the back.

14. Another fixture attaches from the upper coilover bracket to the previously installed control arm pivot.

14. Another fixture attaches from the upper coilover bracket to the previously installed control arm pivot.

15. A final round of welding and the crossmember, control arm, and coilover mounts are finished.

15. A final round of welding and the crossmember, control arm, and coilover mounts are finished.

16. In this case, power rack-and-pinion steering was installed. The customer supplied the brakes and coilovers.

16. In this case, power rack-and-pinion steering was installed. The customer supplied the brakes and coilovers.

17. Like the front, the welds on the rear boxing plates were ground smooth.

17. Like the front, the welds on the rear boxing plates were ground smooth.

18. Dummy rod ends are used to position the four-bar brackets properly. Once the welds cooled, the spacers were removed and the four-bars were installed.

18. Dummy rod ends are used to position the four-bar brackets properly. Once the welds cooled, the spacers were removed and the four-bars were installed.

19. After positioning the upper coilover mounts, a special fixture was used to position the bracket for the Panhard bar.

19. After positioning the upper coilover mounts, a special fixture was used to position the bracket for the Panhard bar.

20. AME builds axlehousings in-house—note the heavy bar used for alignment of the axle flanges.

20. AME builds axlehousings in-house—note the heavy bar used for alignment of the axle flanges.

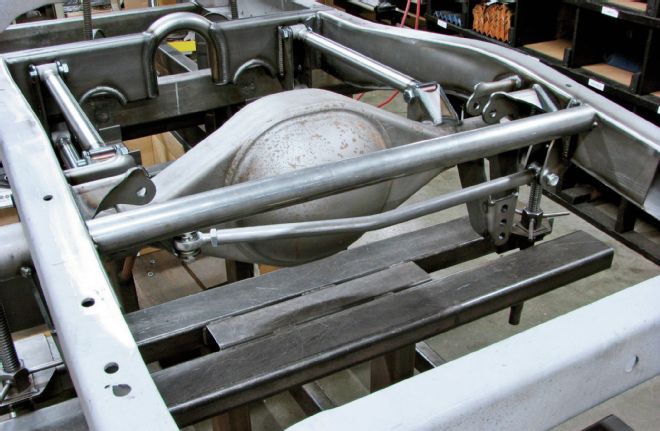

21. The finished housing in place with four-bars and a Panhard rod.

21. The finished housing in place with four-bars and a Panhard rod.

22. A far cry from original, vintage frame that had a straight front axle and leaf springs on both ends, it now has a state-of-the-Art suspension.

22. A far cry from original, vintage frame that had a straight front axle and leaf springs on both ends, it now has a state-of-the-Art suspension.