Sometimes you just have to break the mold. Go against the grain. March to the beat of your own boom box…or something like that.

Everything begins with the framerails and the cross member that the truck arms will mount to. Hess Racing Products has several surface plates and jigs at its disposal for building all types of cars. Here, lead fabricator Chris Cornett sets the framerails parallel and centered on the surface plate. He also knows the frame heights he wants and will have those correct to 1/32-inch before even making the first tack weld.

Everything begins with the framerails and the cross member that the truck arms will mount to. Hess Racing Products has several surface plates and jigs at its disposal for building all types of cars. Here, lead fabricator Chris Cornett sets the framerails parallel and centered on the surface plate. He also knows the frame heights he wants and will have those correct to 1/32-inch before even making the first tack weld.

Need proof? If somebody wasn’t willing to break the mold, we’d still be wearing top hats and calling each other "chap” and "old boy!” And going against the grain gave us breakfast foods for supper, which is always better than eating the same stuff for breakfast, even though nobody knows why.

Going against the grain is also often necessary in racing if you hope to find an advantage over your competition. After all, the only thing that going with the status quo will guarantee you is a mid-pack finish.

That was the thinking when Hess Racing Products set out to build a new Super Late Model asphalt race car for Bill Kimmel. Asphalt SLM touring series like the Pro All Star Series (PASS) or the Champion Racing Association (CRA) occupy a unique place in the racing landscape. It is one of the highest levels of racing where the racers are almost all racing for a hobby, not a profession. The touring format means race teams are at a different racetrack each week with very limited practice time. Tripping up and missing the setup one weekend can throw a real monkey wrench into both your night and your chances at a championship.

To lessen the opportunity to screw up the setup, Hess Racing decided to go against the grain with this SLM chassis. Most cars at this level use a three-link rear suspension setup. The short bars make the rearend more reactive on the track, but missing the setup even by a little can really throw off your lap times. Hess has been building top-level touring cars from NASCAR’s Nationwide Series, to the ARCA series to Pro Cup, all of which utilize a truck-arm rear suspension.

SLM rules do not dictate a stamped or stock floorpan, so Cornett can fabricate the interior exactly how he needs it

1. Packaging is tight, even in a conventional straight-rail car, so getting the larger truck-arm rear suspension to work within the close confines of the chassis will take some engineering. Cornett welds up the truck-arm mounts early in the build so that he can keep an eye on clearances along the way.

1. Packaging is tight, even in a conventional straight-rail car, so getting the larger truck-arm rear suspension to work within the close confines of the chassis will take some engineering. Cornett welds up the truck-arm mounts early in the build so that he can keep an eye on clearances along the way.

2. Cornett will allow the rear wheels to go where they want and then adjust the front clip to get the target 105-inch wheelbase. Here, he has a pattern for the rear kick-up that helps him determine the proper spacing for the fuel cell and the rest of the rear clip.

2. Cornett will allow the rear wheels to go where they want and then adjust the front clip to get the target 105-inch wheelbase. Here, he has a pattern for the rear kick-up that helps him determine the proper spacing for the fuel cell and the rest of the rear clip.

3. All the jigs required to build the chassis will get in the way of the truck arms, so after determining placement and ride height, Cornett sets up a piece of tubing to simulate the rearend to help him set the rear geometry, including jack bolt and Panhard bar mounts.

3. All the jigs required to build the chassis will get in the way of the truck arms, so after determining placement and ride height, Cornett sets up a piece of tubing to simulate the rearend to help him set the rear geometry, including jack bolt and Panhard bar mounts.

4. Here, you can see the rear clip and the beginnings of the rollcage coming together.

4. Here, you can see the rear clip and the beginnings of the rollcage coming together.

5. This is a nice touch. Cornett leaves a section when he cuts the back of the fuel cell cage so that it covers the opening of the tubing it mates to. This keeps moisture and dirt from collecting inside the tubing so it won’t rust from the inside out.

5. This is a nice touch. Cornett leaves a section when he cuts the back of the fuel cell cage so that it covers the opening of the tubing it mates to. This keeps moisture and dirt from collecting inside the tubing so it won’t rust from the inside out.

6. The battery box is located just behind the driver seat as low and as far to the left as possible.

6. The battery box is located just behind the driver seat as low and as far to the left as possible.

7. The left-side rail of the rear clip is moved in just enough for tire clearance. Notice the bracing on both sides of the tubing to stabilize the shock mounts and jack bolt pass-through.

7. The left-side rail of the rear clip is moved in just enough for tire clearance. Notice the bracing on both sides of the tubing to stabilize the shock mounts and jack bolt pass-through.

8. The completed rollcage. Notice how all the bars are kept high on the right side of the car (passenger side). This is to make room for the up-and-over header layout. All the round tubing is 13/4-inch. Major structural components and everything that’s in the car for driver protection are 0.095 wall 1018 seamless tubing. Minor pieces are constructed from lighter and cheaper 0.068 wall 1020 DOM tubing.

8. The completed rollcage. Notice how all the bars are kept high on the right side of the car (passenger side). This is to make room for the up-and-over header layout. All the round tubing is 13/4-inch. Major structural components and everything that’s in the car for driver protection are 0.095 wall 1018 seamless tubing. Minor pieces are constructed from lighter and cheaper 0.068 wall 1020 DOM tubing.

9. Cornett welds up the front clip on a separate jig table. The front clip will be Hess’ standard Super Late Model design.

9. Cornett welds up the front clip on a separate jig table. The front clip will be Hess’ standard Super Late Model design.

10. Here’s a closer look at the nearly complete front clip.

10. Here’s a closer look at the nearly complete front clip.

11. The rear Panhard bar mount sees lots of side loading, so it receives plenty of bracing.

11. The rear Panhard bar mount sees lots of side loading, so it receives plenty of bracing.

12. Here’s another view showing how the interior rollcage bracing is designed to leave room for the headers.

12. Here’s another view showing how the interior rollcage bracing is designed to leave room for the headers.

13. Cornett test fits the mounts for the dry sump oil tank. For best weight distribution, the oil tank mounts just behind the driver.

13. Cornett test fits the mounts for the dry sump oil tank. For best weight distribution, the oil tank mounts just behind the driver.

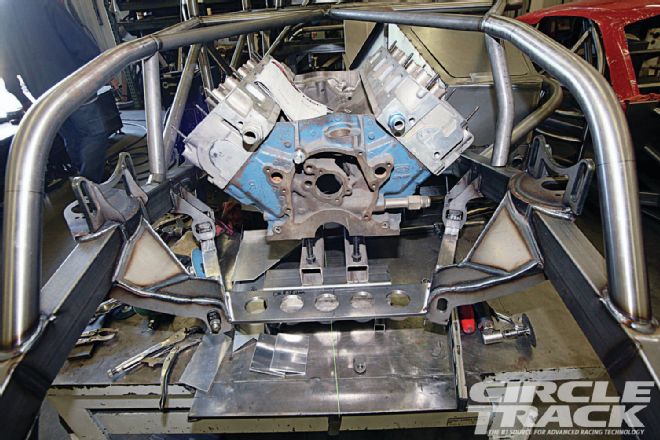

14. If the team already has its engine or just knows the oil pan depth, Cornett can set the engine height as low as possible while still making sure the oil pan is protected by the front crossmember. Here, you can see how he uses a dummy block and heads with bolts threaded into the block’s main webbing to simulate the depth of the oil pan. This allows him to place the engine exactly where he wants it and then fabricates the motor mounts precisely to fit.

14. If the team already has its engine or just knows the oil pan depth, Cornett can set the engine height as low as possible while still making sure the oil pan is protected by the front crossmember. Here, you can see how he uses a dummy block and heads with bolts threaded into the block’s main webbing to simulate the depth of the oil pan. This allows him to place the engine exactly where he wants it and then fabricates the motor mounts precisely to fit.

15. Here is a better angle so you can see the engine setback.

15. Here is a better angle so you can see the engine setback.

A truck-arm suspension uses much longer suspension arms. Those longer arms means less rear steer is created when the chassis rolls to the right side through the turns. Overall, the rearend is more forgiving and missing the perfect setup shouldn’t harm the handling as much. On the other hand, a Super Late Model isn’t as tall as a typical truck-arm car and making the geometry work can be difficult.

We wanted to see how it all came together so we spent several days at the Hess Racing Products shops in Mooresville, North Carolina, documenting the progress of this build from a stack of tubing all the way to a completed rolling chassis. Later, we’ll come back around to hang the body. But for now, we’ve got some serious fabrication to do.

16. This bar protects the driver’s feet in the event of a hard hit just behind the left-front wheel.

16. This bar protects the driver’s feet in the event of a hard hit just behind the left-front wheel.

17. A look at the nearly completed driver’s compartment. SLM rules do not dictate a stamped or stock floorpan, so Cornett can fabricate the interior exactly how he needs it. Notice the kickup on the far side of the floorpan, which was necessary to create clearance for the truck arm.

17. A look at the nearly completed driver’s compartment. SLM rules do not dictate a stamped or stock floorpan, so Cornett can fabricate the interior exactly how he needs it. Notice the kickup on the far side of the floorpan, which was necessary to create clearance for the truck arm.

18. This shot shows the driver’s foot box. The holes are obviously for the clutch and brake master cylinders, and you can see the seam where a different piece of metal is used. Cornett used plate steel for the master cylinder mounting area so that it won’t flex if the driver gets a little “aggressive” with the pedals. Also notice the horizontal bar. This is for the driver to rest his heels on to make driving the car just a little bit less tiring so that he might have an advantage at the end of a long race.

18. This shot shows the driver’s foot box. The holes are obviously for the clutch and brake master cylinders, and you can see the seam where a different piece of metal is used. Cornett used plate steel for the master cylinder mounting area so that it won’t flex if the driver gets a little “aggressive” with the pedals. Also notice the horizontal bar. This is for the driver to rest his heels on to make driving the car just a little bit less tiring so that he might have an advantage at the end of a long race.

19. The seat mounts are built specific to the Joie of Racing seat Kimmel will be using. All mounts connect to major structural components of the car with a direct connection to the rollcage so that the seat will move with the ’cage in the event of a hard left-side hit.

19. The seat mounts are built specific to the Joie of Racing seat Kimmel will be using. All mounts connect to major structural components of the car with a direct connection to the rollcage so that the seat will move with the ’cage in the event of a hard left-side hit.

20. All the gaps on the driver-side of the ’cage are plated better protection.

20. All the gaps on the driver-side of the ’cage are plated better protection.

21. The aluminum racing seat is set in position. From this position it looks like the head support extends outside the ’cage, but it’s an illusion.

21. The aluminum racing seat is set in position. From this position it looks like the head support extends outside the ’cage, but it’s an illusion.

22. Now we’ve finally got the chassis into a finished roller state.

22. Now we’ve finally got the chassis into a finished roller state.

23. A looser rulebook allows Super Late Models to virtually eliminate all the steel outside the right framerail, giving them that famous straight-rail look.

23. A looser rulebook allows Super Late Models to virtually eliminate all the steel outside the right framerail, giving them that famous straight-rail look.

25. A look from the other side of the front suspension. You can also see Cornett’s completed motor mounts.

25. A look from the other side of the front suspension. You can also see Cornett’s completed motor mounts.

24. Hess custom fabricates every component of the front suspension (minus the spring) specifically to the driver’s needs.

24. Hess custom fabricates every component of the front suspension (minus the spring) specifically to the driver’s needs.

26. To the right of this photo you can see where it was necessary to kickup some of the sheetmetal in the driver’s compartment to make clearance for the truck arm to move through the suspension’s travel.

26. To the right of this photo you can see where it was necessary to kickup some of the sheetmetal in the driver’s compartment to make clearance for the truck arm to move through the suspension’s travel.

27. Another view of the completed rear suspension.

27. Another view of the completed rear suspension.

28. The next step in the construction of this brand-new Super Late will be hanging the body, which we will cover in a future issue of Circle Track. So make sure to stay tuned.

28. The next step in the construction of this brand-new Super Late will be hanging the body, which we will cover in a future issue of Circle Track. So make sure to stay tuned.