Franklin Tennessee’s Chris “Kiwi” Slee wanted big horsepower—and especially torque—for his 1966 Mustang coupe—but he didn’t want to spend a fortune. Most ways to a big-horsepower motor involve squeezing lots of boost or nitrous to a heavily fortified engine. But those who’ve used supernatural aspiration know that making big power can get complicated—and expensive—in a hurry. When the mission is big horsepower, the simplest way is to build a supersized engine.

Slee enlisted the expertise of Hendersonville Tennessee engine builder John Bouchard to build an engine for his coupe. Bouchard’s recipe was simple: big cubes, big heads, big carb, big camshaft, with a pump-gas friendly compression ratio.

Chris Slee, owner of Kiwi Classics and Customs in Franklin, Tennesse, is building a 1966 Mustang Coupe that needs a motor. Slee thinks a 557ci big-block Ford fits the bill nicely.

Chris Slee, owner of Kiwi Classics and Customs in Franklin, Tennesse, is building a 1966 Mustang Coupe that needs a motor. Slee thinks a 557ci big-block Ford fits the bill nicely.

The result is a big-block Ford beast with 557 ci, to be exact. That’s 9.1 liters for you youngsters.

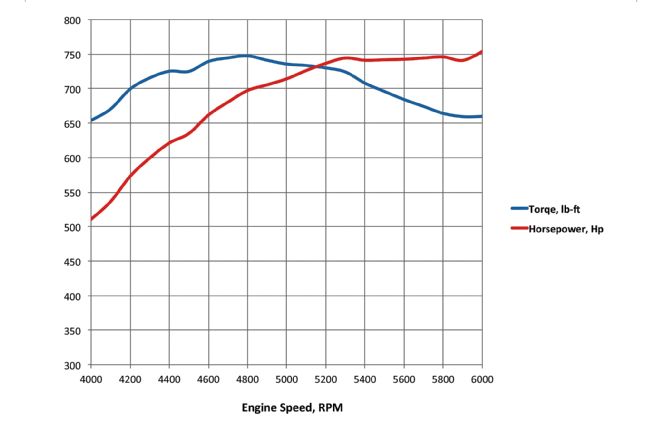

Bouchard estimated 700 hp and 700 lb-ft of torque for a $10,000 budget. Slee’s 557-inch big-block Ford delivered—and then some. Read along for the build, and the dynamometer’s verdict.

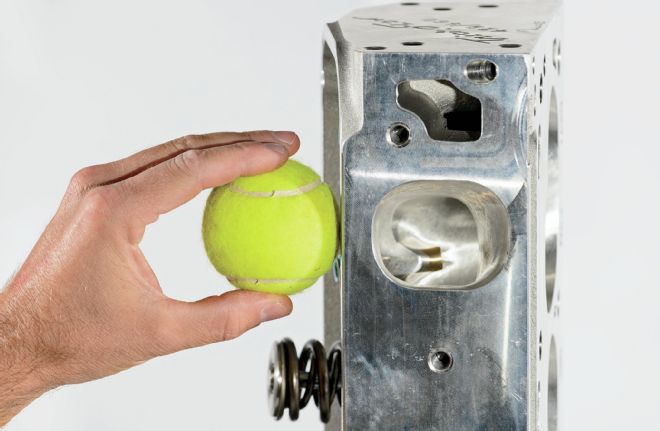

01. To hit the 700-plus horsepower target, we needed the airflow to feed the 557-inch motor. Trick Flow Specialties’ PowerPort 325 aluminum cylinder heads were the obvious choice.

02. To yield 557 ci, John Bouchard Racing Engines stuffed a Scat rotating assembly into a 460 block bored 0.080 over. The kit features a cast, 4.5-inch stroke crankshaft, forged H-beam rods, forged pistons, and file-fit rings.

03. The TFS heads sported CNC-finished, 78cc combustion chambers surrounding 2.200-inch intake and 1.760-inch exhaust valves.

04. The 145cc exhaust ports are equally impressive. These heads can support some serious horsepower.

05. What does a 325cc, CNC-ported intake port look like? To the left is a tennis ball.

06. Trick Flow Specialties’ R-Series intake manifold complements the big airflow potential of the PowerPort 325 heads. The intake matches the heads’ intake ports perfectly, and accepts a 4500 Holley Dominator-style carburetor.

07. After the 460 block was machined at Tommy’s Auto Machine & Parts in Springfield, Tennessee, Bouchard began engine assembly by slipping a custom-ground Com Cams hydraulic roller camshaft into place. The cam lobes measure 0.634/0.626-inch lift and 251/262-degree duration at 0.050-inch lift on the intake and exhaust sides, respectively.

08. Laying the big-block’s cast iron crank into place was a two-man job!

09. Having 557 ci means lots of heavy stuff will be flying around really fast, so Tommy’s Auto Machine & Parts machined the block for splayed, four-bolt main caps. Note the register that located the caps to secure them in place.

10. Bouchard torqued the center cap down first, and applied pressure to seat the thrust bearing on the backside of the cap.

11. Bouchard drove the forged 4.440-inch slugs home with a ring compressor—and the patience of an experienced engine builder.

12. When installing the Trick Flow harmonic damper, Bouchard used a proper installation tool. Even though a crank bolt may work, he recommends always using a proper installation tool.

13. The massive TFS heads were sealed to the block with a Trick Flow multilayer steel head gasket.

14. This 557-inch big-block features Trick Flow Specialties’ 1.73:1 roller rocker arms and hardened pushrods. Trick Flow made the set of pushrods to Bouchard’s specifications.

15. The TFS R-Series intake manifold matched the PowerPort 325 heads perfectly.

16. Trick Flow Specialties’ valve covers cap off the business end of this impressive mill.

17. With the engine mounted on the SuperFlow SF-901 dynamometer at Tommy’s Auto Machine & Parts, Bouchard filled the crankcase up with break-in engine oil and primed the engine with the distributor removed.

18. We hung a set of PN 6224 Hooker Headers on the engine for dyno duty. With 2-inch primaries and 3 1/2-inch collectors, these headers allowed the 9.0L motor to breathe.

19. To feed the beast, Bouchard chose a 1,050-cfm Trick Flow Specialties carburetor. Just a minor adjustment in the idle mixtures and a minor increase in jets got the supersized big-block happy and making power. Bouchard bumped up the jets to 94 front, 100 rear, but final tuning will be done with the engine in the car.

20. Frank Ofria of Tommy’s Auto Machine & Parts elected to limit dyno pulls to 6,000 rpm because the oil pressure started to nose over on the top end. After our dyno session, Bouchard installed a windage tray to better control the oil and keep the oil pump pickup submerged in oil. Regardless, Slee doesn’t see a need for this engine to spin north of 6,000 rpm on the street.

How does 753 hp at 6,000 rpm and 756 lb-ft of torque at 5,400 rpm grab you? With so much torque on tap, Slee figures this 557-inch big-block will give the C6 trans in his ’66 coupe a workout. As Slee describes it, “This motor ought to climb a tree.”

How does 753 hp at 6,000 rpm and 756 lb-ft of torque at 5,400 rpm grab you? With so much torque on tap, Slee figures this 557-inch big-block will give the C6 trans in his ’66 coupe a workout. As Slee describes it, “This motor ought to climb a tree.”

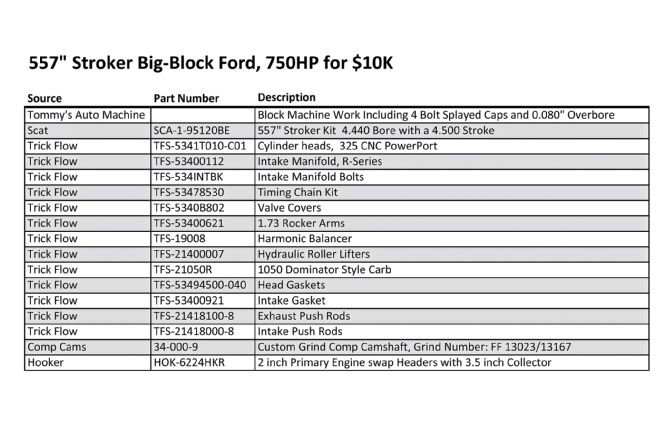

Here’s your shopping list to build your own 750hp big block Ford.

Here’s your shopping list to build your own 750hp big block Ford.