The universe has a weird way of ending things on a poetic note. Richard Petty won his last NASCAR race, Ted Williams homered in his last at bat, and a pair of passionate hot rodders who run the most well-known school for young automotive machinist hopefuls handbuilt the last customer-assembled COPO LS7 engine at the COPO build center in Wixom, Michigan. Linda and Judson Massingill operate SAM, or what's better known as the School of Automotive Machinists (SAMRacing.com) in Houston, Texas. The school owns and races one COPO Camaro already, and when the opportunity came up to add another to their fleet for Linda to race in NHRA stock eliminator competition, they jumped at it. They also took the opportunity to enjoy a businessman's holiday and traveled to Michigan to assemble the actual LS7 427ci naturally aspirated engine that will power their car. What do engine builders do for fun? They build engines, of course!

When Ford launched the factory drag car Cobra Jet program in 2008 and Chrysler soon followed suit, everyone wondered when GM would jump in. The answer was 2012, and since then, COPO factory drag package Camaros have been locking horns with their late-model and classic competition primarily in stock and super stock competition along with specialty factory drag car shootouts. These cars land in the hands of racers. Racers like the crew from the School of Automotive Machinists.

When we asked Judson of SAM why they wanted to add a second COPO Camaro to their drag racing fleet his answer was stone simple: "Firstly, we had the opportunity to acquire a second car," Judson said. "But more importantly than that, we have seen what the drag racing landscape is looking like and how it is changing. Ford, GM, and Chrysler are putting lots of resources into factory style sportsman racing and that's where we want to be." Dr. Jamie Meyer of Chevrolet Performance echoed his sentiments: "Since the COPO program came online in 2012, we've seen the excitement and interest in these cars grow and grow." He continued, "We're excited to have the program continue in 2014 and get more COPO Camaros into the hands of capable sportsman teams like SAM."

The new addition to the fleet is one of the 40 percent of COPO Camaros sold with a stick shift in 2013. Meyer said that even Chevrolet Performance was surprised by that stat: "It is a significant cost to have the car equipped with the stick and it comes 100 percent race ready, not just in the car. We expected the take rate on the stick shift to be a smaller number, but we love to supply the racers with exactly what they need."

Judson tells PHR that this will be Linda's car and she will be the driver. "Years ago when this all got started I had a stick shift Camaro that she raced and was great with, so we expect her to have a lot of fun in this car." Anyone who knows this family's taste in power knows that they roll naturally aspirated and always have. This car will be no different as the power will be derived from an unboosted, unsprayed, unaided-by-anything-but-their-own-brainpower LS7 427ci engine. "We're naturally aspirated people," Judson said with a laugh. "The LS7 is an awesome engine, and we've gotten a lot of great information out of the car that we have been running which we'll apply to this car." It seems most agree, as 75 percent of COPO Camaros sold are equipped with the LS7 engine.

Lest anyone question Linda's skills behind the wheel or her ability, she's a true racer. Having gone 200 mph at the Texas Mile, made countless dragstrip laps, and been a hands-on part of the operation of the School of Automotive Machinists since it opened, Linda has the chops to get in this car and really make the LS7 sing. That is, of course, after it gets some of the touches to its engine that the first COPO on the SAM team has gotten.

1. Here’s Linda Massingill of SAM installing the cam in the engine that will ultimately power her stick-shifted, NHRA stock eliminator COPO Camaro. This is the last engine ever “customer assembled” at the Chevrolet Performance COPO facility in Wixom, Michigan.

1. Here’s Linda Massingill of SAM installing the cam in the engine that will ultimately power her stick-shifted, NHRA stock eliminator COPO Camaro. This is the last engine ever “customer assembled” at the Chevrolet Performance COPO facility in Wixom, Michigan.

2. The assembly process combines the best of both worlds in the gearhead realm with lots of hands-on work along with the ability to use some of the most advanced and precise tools in the world. Here we see some assembly lube being added to the main bearings.

2. The assembly process combines the best of both worlds in the gearhead realm with lots of hands-on work along with the ability to use some of the most advanced and precise tools in the world. Here we see some assembly lube being added to the main bearings.

3. Like we said, cool tools! This crane, with the cool fixture on it makes sure that the crank lands perfectly in the bearing shells and takes all the potential for slipping, dropping, and swearing right out of the equation.

3. Like we said, cool tools! This crane, with the cool fixture on it makes sure that the crank lands perfectly in the bearing shells and takes all the potential for slipping, dropping, and swearing right out of the equation.

4. Slipping the bearings into the main caps as well as adding some lube, Linda gets ready to button down the bottom of the engine. On this line, the customer is working side by side with a GM engine builder who knows all the tricks and specs so the mill will be perfect.

4. Slipping the bearings into the main caps as well as adding some lube, Linda gets ready to button down the bottom of the engine. On this line, the customer is working side by side with a GM engine builder who knows all the tricks and specs so the mill will be perfect.

5. Don’t let the nail job fool ya! Linda is a racer and hot rodder to the core. She’s dropping these main caps on, and beyond that she has gone 200 at the Texas Mile, drag raced a ton, and been an integral part of SAM since the beginning.

5. Don’t let the nail job fool ya! Linda is a racer and hot rodder to the core. She’s dropping these main caps on, and beyond that she has gone 200 at the Texas Mile, drag raced a ton, and been an integral part of SAM since the beginning.

6. Experienced engine builder Judson Massingill said that he was surprised that the same assembly lube formula was used on all surfaces of the engine, from top to bottom. That’s modern manufacturing efficiency for you!

6. Experienced engine builder Judson Massingill said that he was surprised that the same assembly lube formula was used on all surfaces of the engine, from top to bottom. That’s modern manufacturing efficiency for you!

7. If you think your shop and processes therein are neat and organized, Chevrolet Performance has a lesson for you. Note that everything down to the placement of the ring compressor is laid out. That’s precision and that’s why these engines leave working their peak whether the customer builds them or not.

7. If you think your shop and processes therein are neat and organized, Chevrolet Performance has a lesson for you. Note that everything down to the placement of the ring compressor is laid out. That’s precision and that’s why these engines leave working their peak whether the customer builds them or not.

8. With the ring compressor in place and the protective orange guide on the end of the connecting rod, it was time for Linda to slide the COPO slugs into their final home.

8. With the ring compressor in place and the protective orange guide on the end of the connecting rod, it was time for Linda to slide the COPO slugs into their final home.

9. The large wheel at the rear of this photo gives the builder the ability to roll the whole engine over to do things like complete the installation of the connecting rod caps.

9. The large wheel at the rear of this photo gives the builder the ability to roll the whole engine over to do things like complete the installation of the connecting rod caps.

10. With guidance from Chevrolet Performance experts, Linda was soon torquing bolts down on the front of the engine. Amazingly, torque specs are scanned off of a sheet per each component, and the wrench “knows” when to stop. That rules.

10. With guidance from Chevrolet Performance experts, Linda was soon torquing bolts down on the front of the engine. Amazingly, torque specs are scanned off of a sheet per each component, and the wrench “knows” when to stop. That rules.

"We made over 100 passes with the engine in our first COPO before touching anything on the motor," Judson said. "We tried different converters, shock setting, springs, etc., but other than pulling the valve covers off just to see what the hell was in there, we didn't touch anything." After a while, the cam got tweaked, the heads got a little CNC love, and the engine got tuned on the laptop. Those tweaks got the Camaro to a best of 9.34/141-mph in the quarter-mile.

While there have been some insane, heroic numbers thrown down by the supercharged combos available to COPO buyers, we're always intrigued by the racers running naturally aspirated and how they're making the big power and laying down the numbers that they are. To Judson, it's not a matter of whose name is on the engine but the engine itself. "I don't consider myself an 'LS person.' I am an 'air pump person,' but if we're putting things in context, the small-block Chevy is a six and the LS family of engines is a 10," Judson said. "Guys can run 9s on factory heads that were on a 2005 Tahoe, which is totally crazy but when we get to the square/rectangle-port stuff like the LS7...good grief. I know the aftermarket has to hate these heads because they are so, so good."

The LS7's greatness comes from those beautiful cylinder heads that sit atop the short-block and the 427 cubes of displacement it has. Chevrolet's C5R Corvette racing program served as a testbed for the concept that became the LS7 head. It finally came into production as a factory CNC-machined, rectangle-port monster with a 12-degree valve angle and huge 2.20-inch intake valves and 1.610-inch diameter exhaust valves. The valve angle was one of the biggest departures outside of the ports, as LS3 heads have a 15-degree valve angle. Factory stock LS7 heads have been shown to flow 370 cfm on the intake side. That is astronomical stuff for a factory-produced cylinder head. "The two things that are really impressive about the LS7 is that we're talking about an OEM production engine here with such capability as well as the fact that we live in a time where production engines come with a cylinder head with the potential that the LS7 has. You no longer throw factory heads in the trash if you are a hot rodder," GM's Dr. Meyer said.

But what about the situation we told you about in the opening to this story, the one about this being the last customer-built COPO engine ever? The handbuilt engine production line is being moved from where it is now in Wixom, Michigan, to the Corvette facility in Bowling Green, Kentucky. With that move comes the end of the option to build your own engine...for the time being. "They were kind of rolling up the carpet behind us," Judson said. "It is an incredible program, even for a guy like me who does this stuff for a living. To work on the engine with Linda and go through the entire process was really cool. From the level of technology that the builders have access to with their tools, specifically the 'torque wrench' that runs all of the fasteners down on the mains at the same time and does so to the perfect torque spec after it is scanned off of a sheet, to the level of analysis and testing done on the dyno after the engine is built, it was an amazing process to be a part of." The line is a pretty amazing mix of modern ultraefficient manufacturing tools and techniques, and good ol' gearhead know-how. "We think it says a lot for the whole experience if people like Linda and Judson were impressed because they quite literally do this for a living," Dr. Meyer added. Will the option to build your own COPO engine come back? The folks at GM wouldn't rule it out. Stay tuned!

11. With the lifter trays, front cover, and bottom end largely done, it was time to line up and install the valley cover on top of the block. This thing is starting to look like an engine now.

11. With the lifter trays, front cover, and bottom end largely done, it was time to line up and install the valley cover on top of the block. This thing is starting to look like an engine now.

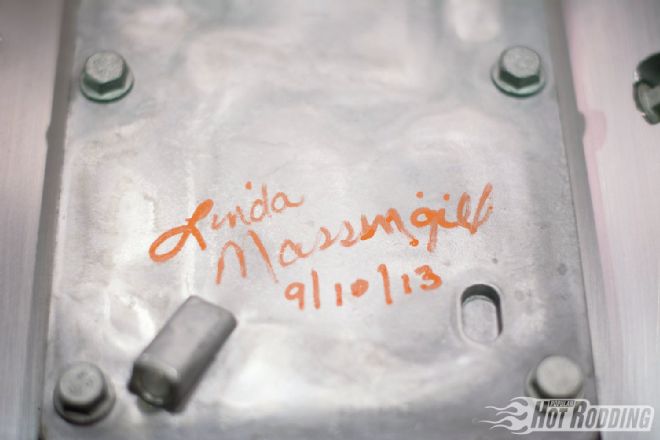

12. Normally when we’re near an engine it is all greasy paw prints. When professionals are around, even their penmanship is nice!

12. Normally when we’re near an engine it is all greasy paw prints. When professionals are around, even their penmanship is nice!

13. You’d be smiling too if you were getting ready to drop a pair of the gnarliest production cylinder heads ever built on top of your engine. The intake valves could be used as umbrellas!

13. You’d be smiling too if you were getting ready to drop a pair of the gnarliest production cylinder heads ever built on top of your engine. The intake valves could be used as umbrellas!

14. Remember this photo the next time you are trying to sling around some iron big-block Chevy heads. Then ask yourself why you don’t have an LS yet!

14. Remember this photo the next time you are trying to sling around some iron big-block Chevy heads. Then ask yourself why you don’t have an LS yet!

15. This is the world’s coolest torque wrench. With the specs installed into the machine, all of the heads attach to corresponding fasteners and with the touch of a button, your heads are torqued down!

15. This is the world’s coolest torque wrench. With the specs installed into the machine, all of the heads attach to corresponding fasteners and with the touch of a button, your heads are torqued down!

16. With the long-block done, it was time for the Holley intake manifold, then it was off to the dyno, where Linda’s handiwork was put to the test and came through with flying colors.

16. With the long-block done, it was time for the Holley intake manifold, then it was off to the dyno, where Linda’s handiwork was put to the test and came through with flying colors.

17. Something like 40 percent of all ’13 COPOs sold were stick shifts and this one is part of that group. That tach will be an integral part of the program when this baby hits the strip with Linda at the wheel.

17. Something like 40 percent of all ’13 COPOs sold were stick shifts and this one is part of that group. That tach will be an integral part of the program when this baby hits the strip with Linda at the wheel.

18. Here she is, ready to rock, roll, and grab Second gear with the front end a couple of feet in the air. Look for this naturally aspirated COPO to be running strong in NHRA stock eliminator action this coming season!

18. Here she is, ready to rock, roll, and grab Second gear with the front end a couple of feet in the air. Look for this naturally aspirated COPO to be running strong in NHRA stock eliminator action this coming season!

19. Here’s Linda, Judson, and the "COPO guys" at Wixom, mugging for the camera after a great day of hard-core gearhead fun.

19. Here’s Linda, Judson, and the "COPO guys" at Wixom, mugging for the camera after a great day of hard-core gearhead fun.