Let's face it, sometimes it can be hard to tell the difference between what is a genuine feature on a product or part that can actually benefit your racing program and what is simply marketing. Sorting the snake oil from the real deal can be difficult—not to mention expensive—so racers often simply resort to copying whatever the local hot shoe is doing.

But if everyone is copying the top dog they run the risk of running the same, which is the opposite of finding an advantage on the competition. We know most Saturday night race teams spend all they have just trying to keep the car running and fuel in the hauler, so money to spend on R&D is about as common as the proverbial hen's teeth.

When everybody has a coating or surface treatment, how can you tell which work the best for your hard-earned dollar?

So we'll do it for you. One of the hottest areas right now is coatings and surface treatments. The reason is because advancing technologies has made applying a coating to racing components much more viable than just a few years ago. Coatings are no longer an exotic—and expensive—frontier technology available to just the Cup teams.

But that gain in popularity means there are a lot of manufacturers trying to get into the game. And when everybody has a coating or surface treatment, how can you tell which work the best for your hard-earned dollar?

One treatment that we've long been curious about is Eagle Specialty Products' ESP Armor. No, we're not talking about protecting yourself from the local psychic. Eagle's ESP Armor is a surface treatment that they can apply to their crankshafts and connecting rods. Exactly how they do it is something Eagle prefers not to share, but we do know that it is a surface treatment, not a coating that is applied to the surface that will eventually wear off. It also doesn't remove metal from the part. Since no metal is ground away, there are not issues with cutting through the heat treatment, and fitting also isn't a problem.

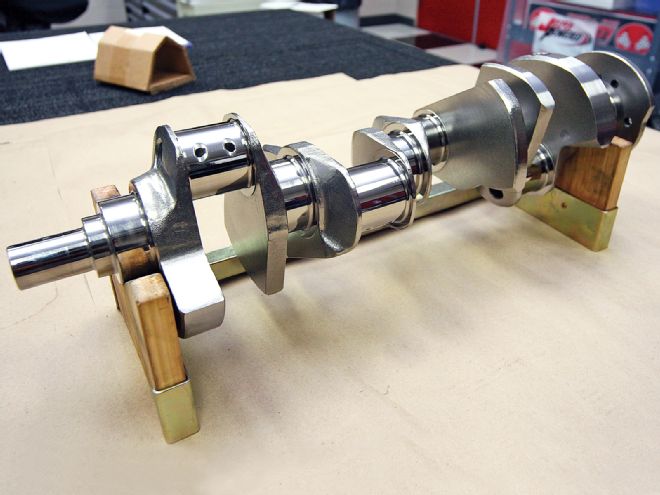

No, this isn’t some chromed ornament in some rich guy’s garage, and it isn’t a high-buck billet, hand-polished crank for a Cup car; this is an off-the-shelf Eagle crank appropriate for a Street Stock level race engine that’s been treated to Eagle’s ESP Armor process. We’re putting this in Circle Track’s dyno mule to see if the surface treatment really is worth horsepower as Eagle claims.

No, this isn’t some chromed ornament in some rich guy’s garage, and it isn’t a high-buck billet, hand-polished crank for a Cup car; this is an off-the-shelf Eagle crank appropriate for a Street Stock level race engine that’s been treated to Eagle’s ESP Armor process. We’re putting this in Circle Track’s dyno mule to see if the surface treatment really is worth horsepower as Eagle claims.

Eagle says that in its own tests it has seen gains of several horsepower in engines similar to those used in circle track racing by adding only an ESP Armor-treated crankshaft. At first numbers like that seems like wishful thinking, after all, the ESP Armor is only a surface treatment meant to smooth the outer surface of the crank. On a properly functioning engine there is no metal-to-metal contact between the crankshaft and the bearings, the crank journals ride on a cushion of oil, so how can smoothing the crank do any good?

The key comes with realizing that the protective film of oil between the crank and the main bearing can be as thin as 0.0005-inch. Any imperfections on the surface of the spinning crank only serves to disturb that thin film of oil, dragging through it can causing parasitic horsepower loss.

Eagle actually provides a very good illustration that explains this very well. Imagine a car travelling down a road through the rain when one of the tires hits a puddle of water. A tire with a sharp, aggressive tread pattern will cut through the water in the puddle and continue to provide traction. But a racing slick with no tread will simply hydroplane right across the top of the water. We don't want our cars hydroplaning across water, but a crankshaft spinning inside your race engine is an entirely different matter. There, a smoother surface will spin inside the protective film of motor oil more easily.

The Eagle ESP Armor treatment isn't just for the journals; it actually covers the entire crank and produces a finish that looks a lot like chrome. Eagle says that by finishing the entire crank, it also helps the counterweights shed oil more easily, which should help reduce windage. Coating the entire crank has also been shown to keep oil temps down.

These are some pretty amazing claims, and if true will definitely help any race engine. Best of all, a surface treatment is permanent, so as long as the crank isn't harmed or has to be ground, the ESP Armor treatment will not wear out or lose its effectiveness.

We decided to put these claims to the test with the help of our friends at UTI's NASCAR Technical Institute (NTI). The school has complete engine building facilities (along with chassis fabrication, setup and almost all other areas involved in working in the racing industry) and almost every member of its teaching staff has professional experience working with a race team or engine builder. We're comfortable working with the school because of the level of expertise available, and they are willing to run our stuff on their engine dyno because it gives their students an opportunity to gain additional experience working on something different.

We contacted the folks at Eagle and they were more than eager for us to put their ESP Armor to the test. To do it right we decided to run a new, untreated Eagle crankshaft in an engine on the dyno to establish a baseline. Then we'd pull the crank, send it to Eagle for the ESP Armor treatment, put it back in the engine and dyno it again. That means two assemblies, one disassembly and two dyno sessions. That's a lot of work, and we were definitely grateful for the assistance of NTI's students and the expertise of instructor Doug Wolfe.

For a motor we dug out Circle Track's old dyno mule. It started out as a standard Chevy crate motor but over time it has evolved with a few upgrades. Now it's outfitted with a pair of RHS cast-iron cylinder heads, Lunati 1.5:1 aluminum rockers, a Weiand dual-plane intake, and a Comp Cams solid roller camshaft with 254/260 degrees of duration and 0.419/0.416 lobe lift.

Until now, the bottom end was stock, complete with powdered metal rods and cast pistons. But since the crank had to be changed anyway for an Eagle unit, we took advantage of the opportunity to upgrade the entire rotating assembly. In addition to the forged crankshaft (with stock 3.500 stroke), Eagle also sent over a set of 5.700 steel rods that are much stronger than the stock powdered metal rods. The pistons are Max 23 forged aluminum pieces. All told, the rotating assembly is significantly stronger than the stock components, and that will allow us to go quite a bit more extreme with our dyno tests in the future.

So what did we learn from our testing? Read on and find out!

1 The block is a standard Chevy small-block with four bolt mains and a two-piece rear main seal. It has never been in a race car but has been through the wringer several times in our dyno tests. To make sure everything is squared away for this test, we touched up the mains with a line hone to ensure the bed for the crank is nice and straight.

1 The block is a standard Chevy small-block with four bolt mains and a two-piece rear main seal. It has never been in a race car but has been through the wringer several times in our dyno tests. To make sure everything is squared away for this test, we touched up the mains with a line hone to ensure the bed for the crank is nice and straight.

2 Since we had to pull the rotating assembly to install the new Eagle crank, we decided this would be a great time to go ahead and upgrade the rest of the rotating assembly so that we can be confident the bottom end will be able to stand up whatever we throw at it in this—and any future—tests.

2 Since we had to pull the rotating assembly to install the new Eagle crank, we decided this would be a great time to go ahead and upgrade the rest of the rotating assembly so that we can be confident the bottom end will be able to stand up whatever we throw at it in this—and any future—tests.

3 The rods are 5.7 inch Eagle H-beam units that are both lighter and quite a bit stronger than the stock I-beam rods.

3 The rods are 5.7 inch Eagle H-beam units that are both lighter and quite a bit stronger than the stock I-beam rods.

4 Pistons are Wiseco forged aluminum flat-tops. Wiseco calls these its Max 23 pistons, and they feature a strutted slipper skirt and short 2.250 wrist pin for excellent strength with light weight.

4 Pistons are Wiseco forged aluminum flat-tops. Wiseco calls these its Max 23 pistons, and they feature a strutted slipper skirt and short 2.250 wrist pin for excellent strength with light weight.

5 To eliminate as many variables as possible, we’ll reuse everything we can between the two tests. But we won’t reuse the head gaskets, so Cometic sent us two sets of its excellent multi-layer steel (MLS) gaskets. We’ve used these in previous engine builds that have seen regular abuse on the racetrack and have never let us down.

5 To eliminate as many variables as possible, we’ll reuse everything we can between the two tests. But we won’t reuse the head gaskets, so Cometic sent us two sets of its excellent multi-layer steel (MLS) gaskets. We’ve used these in previous engine builds that have seen regular abuse on the racetrack and have never let us down.

6 For testing, Eagle sent us a 4340 forged crank that’s quite representative of what is used in race engine builds for a variety of circle track classes. KT Engine Development helped us balance the crank to match the Eagle/Wiseco rotating assembly.

6 For testing, Eagle sent us a 4340 forged crank that’s quite representative of what is used in race engine builds for a variety of circle track classes. KT Engine Development helped us balance the crank to match the Eagle/Wiseco rotating assembly.

7 To give the untreated crank every opportunity in this test, after the balancing process was complete KT Engines also polished the journals to make them as smooth as possible.

7 To give the untreated crank every opportunity in this test, after the balancing process was complete KT Engines also polished the journals to make them as smooth as possible.

8 Because we are testing how a crankshaft can affect engine power, we considered proper bearing fitment to be crucial. We used King bearings for both the rods and mains and main bearing clearance was held between 0.0024- and 0.0025-inch.

8 Because we are testing how a crankshaft can affect engine power, we considered proper bearing fitment to be crucial. We used King bearings for both the rods and mains and main bearing clearance was held between 0.0024- and 0.0025-inch.

9 Here’s the bottom end all buttoned up and ready to roll, or, more accurately, spin.

9 Here’s the bottom end all buttoned up and ready to roll, or, more accurately, spin.

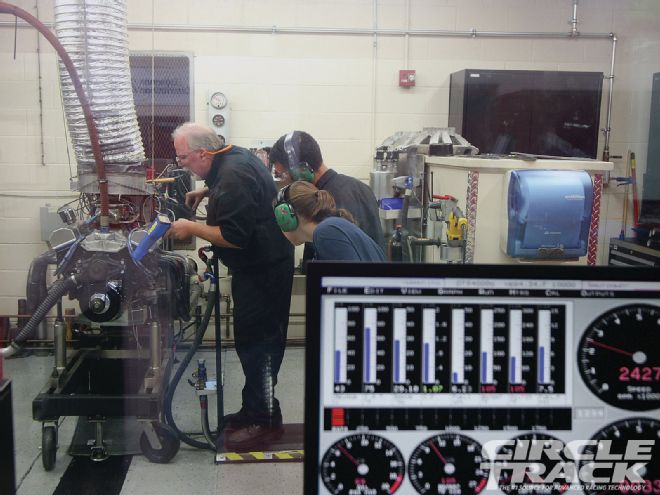

10 We depended on the students to help with both assembly and disassembly as well as preparing the engine for the dyno. They worked under the watchful eye of instructor Doug Wolfe, and we were consistently impressed with how prepared they were for the task.

10 We depended on the students to help with both assembly and disassembly as well as preparing the engine for the dyno. They worked under the watchful eye of instructor Doug Wolfe, and we were consistently impressed with how prepared they were for the task.

11 Because we would be looking for differences of just a few horsepower, repeatability was paramount. Because of this, Wolfe took over at critical moments, such as when it was time to ensure the valve lash was precisely set at 0.018-inch for both the intakes and exhausts.

11 Because we would be looking for differences of just a few horsepower, repeatability was paramount. Because of this, Wolfe took over at critical moments, such as when it was time to ensure the valve lash was precisely set at 0.018-inch for both the intakes and exhausts.

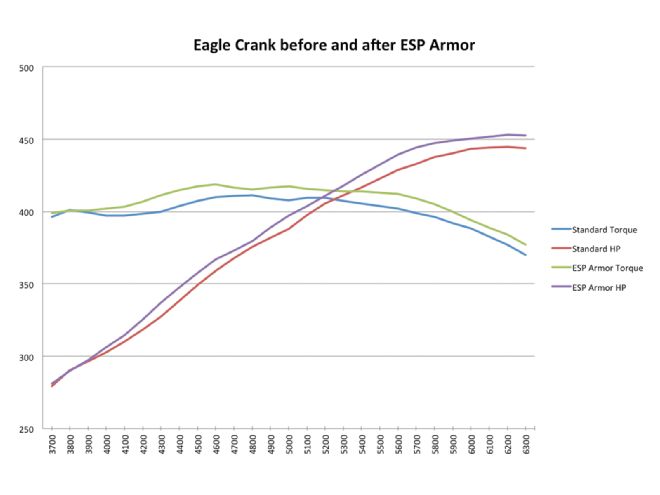

12 The first runs were made on the dyno with the Eagle crank untreated. It performed well, with peaks of 445 horsepower at 6,200 rpm and 411 lb-ft of torque at 4,800 rpm.

12 The first runs were made on the dyno with the Eagle crank untreated. It performed well, with peaks of 445 horsepower at 6,200 rpm and 411 lb-ft of torque at 4,800 rpm.

13 But before Wolfe made those first pulls to get those numbers, he put the dyno mule through a pretty vigorous break-in. Over time a race engine can pick up a few horsepower as the rings seat to the cylinder bores. We didn’t want that to skew the results, so Wolfe pushed the engine pretty hard until it settled in, and only then did he begin making power pulls.

13 But before Wolfe made those first pulls to get those numbers, he put the dyno mule through a pretty vigorous break-in. Over time a race engine can pick up a few horsepower as the rings seat to the cylinder bores. We didn’t want that to skew the results, so Wolfe pushed the engine pretty hard until it settled in, and only then did he begin making power pulls.

14 As soon as the first round of dyno pulls were complete, NTI’s students began tearing down the mule and the crank was shipped back to Eagle to receive the ESP Armor surface treatment. Eagle put the crank through its proprietary process, shipped it back to the school, and the students put the engine back together again. The pistons went back into the same holes and the same bearings were used. We checked, and the bearing clearances had not even changed noticeably.

14 As soon as the first round of dyno pulls were complete, NTI’s students began tearing down the mule and the crank was shipped back to Eagle to receive the ESP Armor surface treatment. Eagle put the crank through its proprietary process, shipped it back to the school, and the students put the engine back together again. The pistons went back into the same holes and the same bearings were used. We checked, and the bearing clearances had not even changed noticeably.

15 After reassembly, Wolfe and his crew of students put the engine back on the dyno for round two. Here, Wolfe goes through an entire checklist to make sure the engine is set up exactly as before. This included valve lash, timing, plug gaps, water and oil temps, you name it.

15 After reassembly, Wolfe and his crew of students put the engine back on the dyno for round two. Here, Wolfe goes through an entire checklist to make sure the engine is set up exactly as before. This included valve lash, timing, plug gaps, water and oil temps, you name it.

16 And here are the results. It turns out that Eagle’s ESP Armor does, in fact, provide a very real benefit to engine power. Both horsepower and torque are improved throughout the rpm range. We chose a typical on-track rpm operating range of 4,000 to 6,000 rpm, and across that span the average torque improved by nearly 8 lb-ft and the horsepower did the same. And while it isn’t nearly as sexy as horsepower, we also noticed that the mirror-like surface created by the ESP Armor process helped maintain lower oil temps, which is also a definite plus.

16 And here are the results. It turns out that Eagle’s ESP Armor does, in fact, provide a very real benefit to engine power. Both horsepower and torque are improved throughout the rpm range. We chose a typical on-track rpm operating range of 4,000 to 6,000 rpm, and across that span the average torque improved by nearly 8 lb-ft and the horsepower did the same. And while it isn’t nearly as sexy as horsepower, we also noticed that the mirror-like surface created by the ESP Armor process helped maintain lower oil temps, which is also a definite plus.