When the topic turns to big-block Mopar wedge power, invariably Indy Cylinder Head is a key part of the conversation. Having pioneered the development of high-flowing cylinder heads for the big Mopar, Indy played a major role in popularizing the performance potential of these engines. The Indy strategy centered upon new aluminum castings in the days dominated by undersized stock iron, opening the wedge’s potential. The voluminous new ports afforded by the Indy heads were made possible by using substantially longer valves than the compromised OEM units, gaining the much needed room to incorporate high-flowing ports in their cylinder head design. Indy’s original cylinder heads revolutionized Mopar big-block wedge performance, bringing real horsepower to the masses. From those beginnings, Indy has been continuously expanding its big-block Mopar product line to include virtually everything needed to build a complete aftermarket wedge engine.

This is exactly the project we embarked upon last month (“The Indy Maxx 500, Part I,” May ’13), when we detailed the building of a 500-inch low-deck Mopar wedge bottom end based upon an Indy Maxx aluminum block. Rather than look to build an engine to show maxed-out numbers on the dyno, our goal with this engine is to build a reliable and street-capable powerhouse wrapped in a lightweight package that weighs about the same (or close to) the all-iron slant-six in our ’68 Valiant project car. To this end, high torque, moderate rpm, and conservative cam specifications would provide reliable street power that will perform over the long haul with a minimum of hassles. In fact, Indy’s engine builder, Ken Lazzari, worked hard to run as little cam as practical without unduly hampering output. When the short-block was assembled, the cam selected was a COMP solid flat tappet grind with just under .600-inch lift, and 245/250 degrees duration at .050-inch lift. Lazzari was looking to make the most of the power curve while keeping peak horsepower rpm right around the 6,000 rpm number.

Big-Block Top-Up

Keeping in mind the intended powerband and desired operating rpm range, Lazzari selected Indy’s 440 EZ-1 cylinder heads. The EZ line of cylinder heads are differentiated from other Indy big-block heads by a standard exhaust port location, in contrast to the raised exhaust of the other Indy offerings. The Indy EZ head configuration relieves clearance and fit issues that can arise with most commonly available headers, especially when the big-block wedge is shoehorned into the tight confines of Mopar’s popular A-Body vehicles. The EZ series of heads come in several variations, with the basic 440-EZ version featuring as-cast ports, with a 270cc intake port having the standard production big-block port window. The 440 EZ-1 steps up the specifications with the intake port window CNC machined to the Max Wedge dimension, as well as additional CNC work in the bowl for improved flow. Indy also offers fully CNC-ported EZ heads, with the 295cc “Little Easy,” and the offset rocker 325cc “Big Easy.” With our moderate rpm goals and relatively restrained cam timing, the 275cc 440 EZ-1 was the practical choice.

Since Indy Cylinder Head performs all the finish machining and final CNC work on their raw cylinder head castings, their 440 EZ heads are available in a variety of configurations. Variations include the “as-cast” 270cc with standard port window, the partially CNC-ported 275cc Max Wedge EZ-1, the fully CNC-ported 295cc Max Wedge Little EZ, and the fully CNC-ported 325cc offset rocker Max Wedge Big Easy.

Since Indy Cylinder Head performs all the finish machining and final CNC work on their raw cylinder head castings, their 440 EZ heads are available in a variety of configurations. Variations include the “as-cast” 270cc with standard port window, the partially CNC-ported 275cc Max Wedge EZ-1, the fully CNC-ported 295cc Max Wedge Little EZ, and the fully CNC-ported 325cc offset rocker Max Wedge Big Easy.

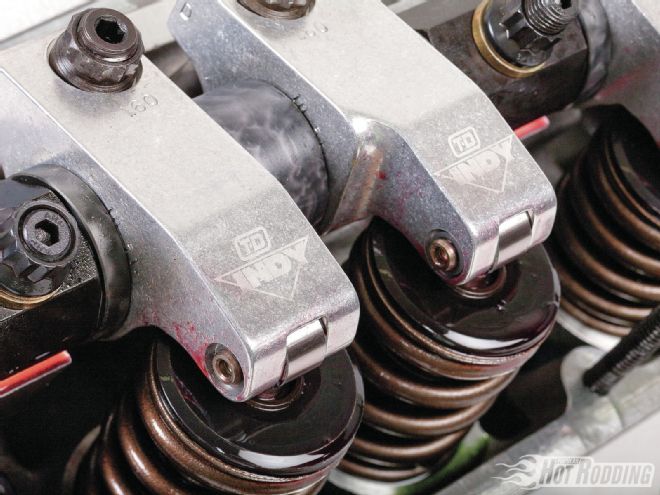

Our completed short-block was built with Diamond full dish pistons, resulting in a compression ratio of 10:1 with the 75cc chamber volume of the EZ-1 cylinder heads. The heads were assembled by Indy with a set of COMP dual springs providing 140 pounds seat load and 375 pounds at full lift, using COMP steel retainers and 10-degree locks. A Fel-Pro number 1009 head gasket clamped by a set of ARP bolts secured the heads to the deck, as our 500ci low-deck wedge entered final assembly. With the cylinder heads in place, the valvetrain was completed with a set of Indy ⅜-inch pushrods, working a team of Indy/T&D shaft-mounted 1.6:1-ratio rockers.

With the Max Wedge intake port configuration, intake manifolds for the standard big-block wedge will not fit the enlarged port window. There are, however, a wide range of intake manifolds available specifically for the Max Wedge, including an excellent high-rise single-plane from Indy. While this Indy single four-barrel manifold would be hard to beat from a strict performance perspective, we were looking for something just a little bit more unique for our application. Indy had exactly what we were after with their new Mod Man modular intake manifold system. The Mod Man arrangement uses an open plenum base in tandem with one of four available top plates to provide a range of possible inductions. Top plates can be had in single four-barrel, inline dual-quad, three two-barrel “Six Pack,” or supercharger configurations. For our street wedge, the single four-barrel unit would have been satisfactory, but we went with the dual-quad arrangement to significantly increase the underhood appeal of our engine combination. The Mod Man inline dual four-barrel top plate readily accepts a pair of Edelbrock Performer Series carbs. Given that Mopar showcased similar AFB-style carbs in their factory inline dual-quad Hemi muscle cars, as well as in earlier dual-quad wedge applications, the Edelbrock carbs were the natural choice for our wedge build. Indy spec’d a pair of Edelbrock #1404 500-cfm carbs, along with Edelbrock’s dual-quad linkage kit. With the heads, valvetrain, and induction system in place, the finishing touch was a pair of Indy cast-aluminum valve covers.

For our low-deck 500-cube aluminum street wedge’s goals of street torque and moderate rpm, Indy went with the 275cc EZ-1. These heads feature CNC profiling of the port window to Max Wedge dimensions, as well as CNC porting in the all-important bowl area.

Viewed from the intake port side, the large port window and CNC work to the intake port entrance is readily apparent. The heads were set up by Indy with a COMP spring package compatible with a solid flat-tappet camshaft using a dual spring assembly, steel retainers, and 10-degree locks.

The assembly of our aluminum Maxx block bottom end was detailed in the May issue of PHR. In preparation for installing the Indy EZ-1 cylinder heads, the decks received a set of ARP studs. With a 0.039-inch Fel-Pro 1009 gasket and the full-dished Diamond pistons, the compression ratio works out to a pump gas–friendly 10:1.

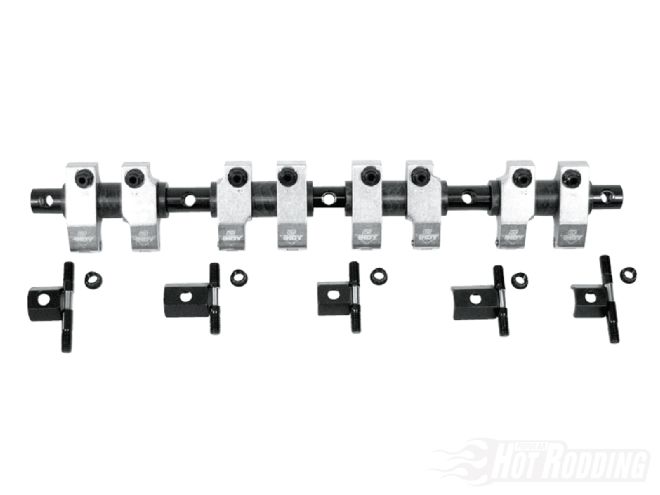

With the T&D 1.6:1 ratio rockers the custom COMP solid-lifter camshaft (grind number CRB3-6579-6583-S108) delivers a gross valve spec of .594/.612 inch. The valve lash was set to .018 inch (hot) on both the intake and exhaust.

For a traditional hot rod look, it is hard to beat the appearance of an inline dual-quad system. Indy’s Mod Man intake manifold features a two-piece construction with interchangeable tops, including the dual four setup selected for our aluminum wedge.

Taking the motion of the COMP solid flat-tappet planted in the block is a set of Indy/T&D 1.6:1 ratio aluminum shaft-mounted rockers. These rockers are designed to bolt in using the production-style rocker saddles cast into the heads. T&D makes a complete line of off-the-shelf Mopar shaft-style rocker arms for small-block, big-block wedge, and Hemi applications, but these T&D rockers are made specifically for the Indy EZ-1 and are only available through Indy Cylinder Head.

The flexible Mod Man intake allows a broad range of popular induction options simply by replacing the top plate. Top plates include a blower mount, single four-barrel, Six Pack three two barrels, or the dual quad top used in our application.

A pair of 500-cfm Edelbrock carbs, #1404, is the perfect complement for the Indy Mod Man intake, providing a look that is reminiscent of the bygone muscle cars familiar to Mopar enthusiasts. With a total flow capability of 1,000 cfm, there’s more than enough to feed our hungry 500 incher!

Fully assembled and ready for the dyno, Indy’s dual-quad aluminum wedge was nothing short of a thing of beauty. For dyno trials, the engine would be fitted with a Meziere electric water pump and a set of 2⅛-inch dyno headers. We may be restricted in our choice of headers with the Valiant; a set of custom units may be our best choice to fit in the A-Body’s chassis.

Lighting the fire is a full array of ignition components from MSD, including their Pro Billet distributor, 6AL ignition box, Blaster II HVC coil, and secondary wires. Indy’s Ken Lazzari tells us Indy chooses MSD components because they’re consistent and reliable.

To The Dyno

The final details of our engine assembly included a full ignition system from MSD, including their Pro Billet distributor, 6AL ignition box, and wires. The engine was moved from the engine-building area of Indy Cylinder Heads to their well-equipped dyno cell for testing on the SuperFlow engine dyno. For testing, the engine was fitted with a Meziere electric water pump and Indy’s 2⅛-inch dyno headers. After the successful initial firing, adjustment, and warm up, the ignition timing was set to 35 degrees total advance and the valves adjusted to .018 inch hot. The combination was run at a test acceleration rate of 600 rpm per second, sweeping from just below peak torque to well past peak power.

Bolted to the Indy SuperFlow dyno, the aluminum wedge was able to prove its capabilities. Tested at an acceleration rate of 600 rpm per second, the street combo delivered 662 lb-ft of torque at 4,500 rpm, with 657 peak horsepower on tap at 6,100 rpm.

Bolted to the Indy SuperFlow dyno, the aluminum wedge was able to prove its capabilities. Tested at an acceleration rate of 600 rpm per second, the street combo delivered 662 lb-ft of torque at 4,500 rpm, with 657 peak horsepower on tap at 6,100 rpm.

The information display showed peak power coming in at 6,100 rpm, essentially right on our operating rpm range target, with 657 hp recorded. The dyno pull extended through to 6,700 rpm, with no sign of valvetrain instability apparent, while retaining 644 hp at that engine speed. Equally impressive, the engine showed it was making excellent torque throughout the test range, delivering a maximum of 662 lb-ft of torque at 4,500 rpm. Calculating the specific torque per cubic inch showed the engine was making very efficient use of its displacement, with over 1.32 lb-ft of torque per cubic inch, an outstanding level for a pump-gas engine. This compact and lightweight big-block Mopar was making Goliath power in just the sweet range for a true street application. Weighing in at about the mass our original iron Slant-Six, but with nearly six times the power output, this Indy Wedge is just the thing to take the street performance of our Project Valiant to the Maxx.

Now the task ahead of us this year is shoehorning our Indy Maxx 500 under the flat hood of our ’68 Valiant project car. With over 650 hp on tap, it means revamping the entire driveline, including a Reilly Motorsports AlterKtion front and Street Lynx rear suspension, QA1 adjustable Stocker Star shocks, a Strange S60 rearend, a TCI Automatics Street Fighter 727 TorqueFlite, and Wilwood disc brakes. If we do everything right, it will retain the stealthy look you see right here. Watch the Violent Valiant unfold right here!

Now the task ahead of us this year is shoehorning our Indy Maxx 500 under the flat hood of our ’68 Valiant project car. With over 650 hp on tap, it means revamping the entire driveline, including a Reilly Motorsports AlterKtion front and Street Lynx rear suspension, QA1 adjustable Stocker Star shocks, a Strange S60 rearend, a TCI Automatics Street Fighter 727 TorqueFlite, and Wilwood disc brakes. If we do everything right, it will retain the stealthy look you see right here. Watch the Violent Valiant unfold right here!