Jeff Abbott’s ’54 Olds Rocket now wears a modern A/C compressor, alternator, and power steering pump, thanks to Street Rod Bracketry.

Jeff Abbott’s ’54 Olds Rocket now wears a modern A/C compressor, alternator, and power steering pump, thanks to Street Rod Bracketry.

Like many of those giving a ’50s car a street rod redo, Jeff Abbott decided to keep the original engine in his ’54 Oldsmobile Holiday 98. After all, there’s really no need for an engine swap—the 324-inch Rocket V-8 has a huge cool factor and it provides more than enough propulsion to get the Olds down the road. What it doesn’t have are the mounts for modern components, like an alternator or a contemporary air-conditioning compressor and power steering pump.

As the lead design engineerat Perfect Performance Products, Abbott has high standards and knows what it takes to create a quality aftermarket product. So for the pieces needed to update the Olds he turned to Roe Creager at Street Rod Bracketry. Creager offers a kit with brackets, harmonic balancer, 100-amp Painless Powerstar alternator, and a Sanden Style A/C compressor.

Installing the kit is a simple process; Abbott documented the procedure as Creager swapped old components for new. The end result was a vintage Olds engine with securely mounted modern accessories—that’s our idea of rocket science. Here’s how it’s done.

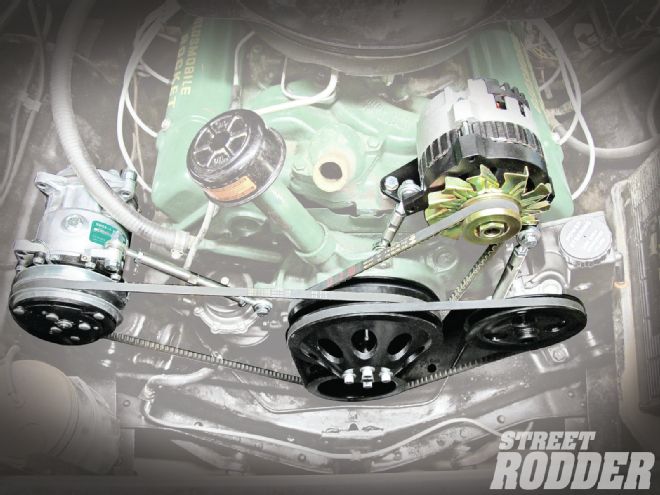

This is the complete kit for the Olds conversion. Included are a custom vibration damper with an integral three-groove pulley, brackets, adjusters, alternator, power steering pump, A/C compressor, belts, and hardware. Brackets for Nailhead Buicks are also available.

In stock form the Olds had a generator attached to the passenger-side exhaust manifold and a power steering pump mounted to the intake.

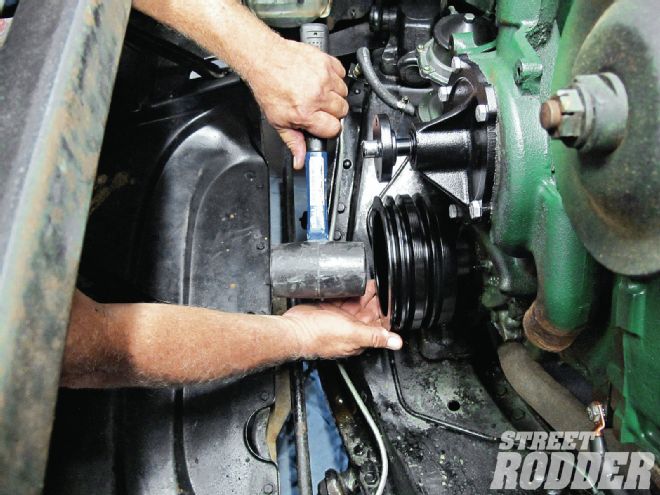

The damper/pulley assembly is a slide-on fit. It can be put in position by gently tapping with a dead-blow plastic hammer.

Jeff opted for a black anodized water pump pulley. As part of the A/C installation the original four-blade mechanical fan will be replaced with an electric.

After the power steering pump and mounting bracket are removed, the new alternator bracket will go in its place.

Jeff gladly gave the original generator the heave-ho. It was rated at 30 amps at 2,150 rpm, barely enough to keep the battery charged without any electrical accessories.

A new A/C compressor bracket replaces the mount for the generator. For engines with headers or manifolds without a mount, a head-mounted bracket is under development.

With the new bracket installed, the Sanden A/C compressor attaches to it with a single bolt.

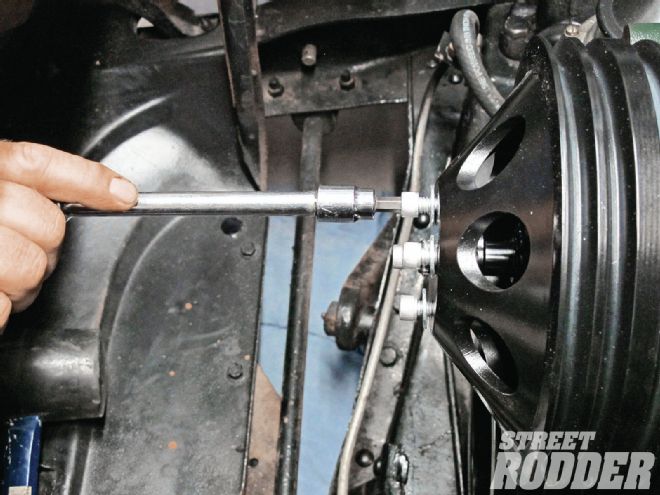

The only modification to the engine required is drilling and tapping the old generator strap-mounting boss to accept a 3/8-16 cap screw.

After tapping the water pump housing the tension rod for the A/C compressor is installed. To make adjustment easy it is equipped with left and righthand rod ends.

This is the new bracket for the power steering pump—it bolts to the head and also ties into the new alternator mount for reinforcement.

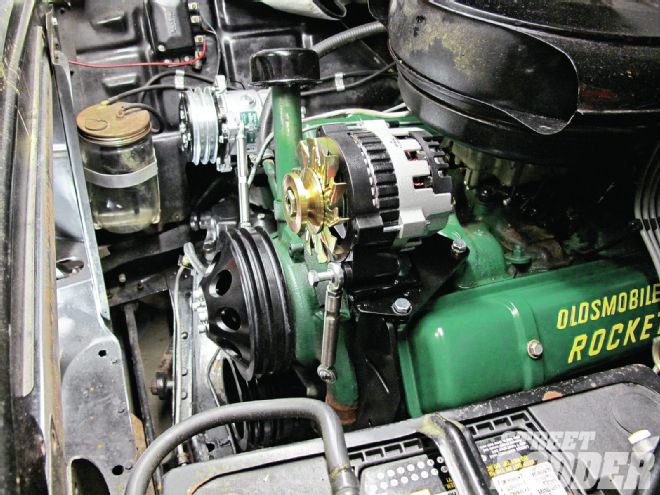

Once the power steering pump bracket is in place the alternator mount can be bolted to it and the intake manifold.

Here the new Painless alternator is in place. The link on the alternator bracket will tension the power steering pump belt. Note the original glass windshield washer reservoir.

Another adjustable link to tighten the alternator belt attaches to the water pump housing.

The final step is the installation of the new Saginaw power steering pump and final adjustment of all the belts.