There are a few options for C10 owners when it comes to gas tank relocation, but they all seem to have one drawback or another. Be it mounting location, size, fitment issues, or filler location, rarely does one find that what's available facilitates his or her every need. Most of this is due to the fact that what's available is based on a different make or model. Gas tanks from similar vintage Blazer and Suburban trucks seem to be the most commonly used for '67-up C10 pickups, but their larger size means that they can hang a bit lower than may be desired. There also exists the issue of what to do with the filler. These tanks are often not fully baffled like a late-model tank, an issue that can cause problems when fitting a tank-mounted fuel pump, which is common in EFI systems.

We ran across these problems recently when we decided to move the stock fuel tank under the back of the bed on an '86 Chevy C10. We wanted to add a baffled, in-tank fuel pump from Aeromotive to facilitate the EFI system on the E-ROD LS3 crate motor from Chevrolet Performance, while retaining enough capacity so that we wouldn't have to stop for gas every 50 miles. But we also didn't want the tank to be so large that it would hang under the bumper for aesthetic reasons, nor did we want it to be so low that it would drag on steep driveways. The solution we came up with was to contact Rock Valley Antique Auto Parts to have them build us a custom, one-off fuel tank out of corrosion-resistant stainless steel.

Rock Valley's fuel tank department has been manufacturing factory replacement and custom fuel tanks for over 30 years and can whip up a custom tank based on a customer's specified drawings or samples. Jason Scudellari, our tech center manager, decided to get crafty for this project and busted out the 316-inch foam board and hot glue gun in order to fabricate a life-size sample for the guys at Rock Valley to duplicate out of stainless. This process allows the customer to make minute changes to their design and test fit it before sending the plans off to Rock Valley, leaving the guesswork out of the equation. A custom approach to a truly custom application.

1-2. The first step in fabricating a new tank is to take a base set of measurements given the area to work within. The height and length measurements are taken first so that the shape of the sides of the tank can be determined.

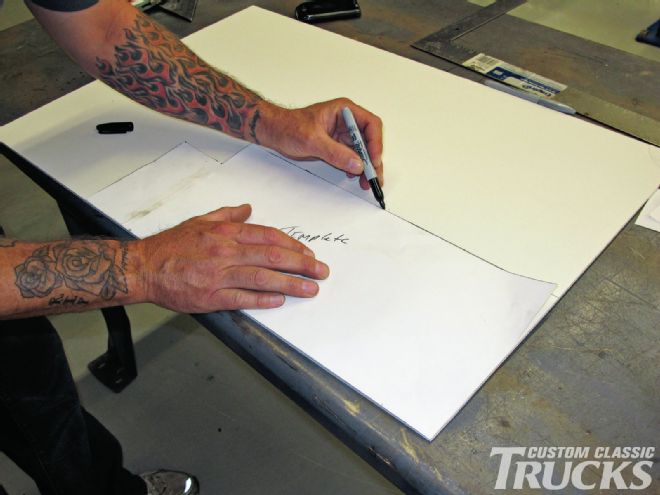

3. These are then transferred to a paper template

4. which are then transferred to 316-inch foam board.

5. Next, the width of the tank is determined and a foam board panel is created within those parameters.

6. A straight edge and a sharp razor knife ensure the pattern is cut out perfectly.

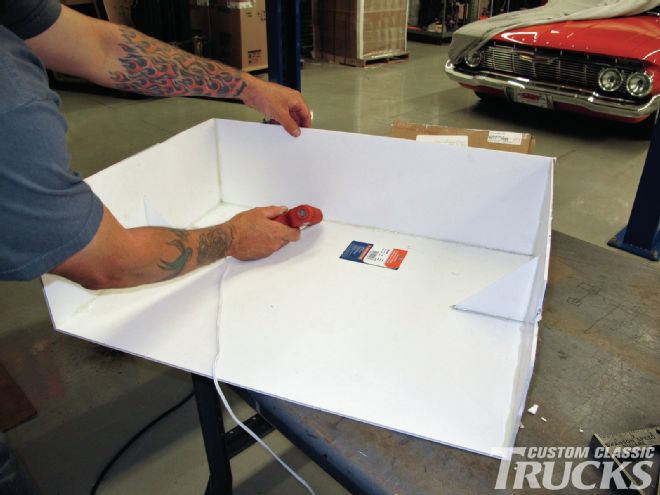

7. A hot glue gun mates the side panel with the new bottom panel, ensuring that everything remains square.

8. A gusset is added to keep the side from collapsing, while the rest of the pattern is fabricated. Obviously, this gusset won't be necessary on the finished stainless version as it only functions to support the strength of the foam core pattern.

9. The dimensions for the rear panel are then taken from the foam core pattern

10-11. before it's cut and glued in place as well.

12. This same process is applied to the front panel as well.

13. To maximize capacity, Jason designed a step in the rear of the tank to clear one of the bed cross sills.

14. This is where experience starts to show. The amateur pattern builder might forget that the fuel fittings will stick up quite a bit higher than the top of the tank, forcing the tank to be installed at a lower height. Jason planned for this and incorporated a recessed area so that the outlet, return, vent, and wiring for the fuel pump and sender will clear the bed floor without an issue.

15. The last piece of the puzzle is to mock the pattern up into position one final time to double check any fitment issues that may have gone unnoticed. This is also a good time to locate any mounting tabs that might be desired. This tank will bolt directly to the frame rails as opposed to being supported by a pair of stainless steel straps. Note the clearance given thanks to the tank being mounted as high as possible in the chassis.

16. With the pattern still installed under the truck, it's also a great time to locate the filler neck and to mark that on the pattern so that Rock Valley will install it in the exact spot specified.

17. A few short weeks later and we had a complete, one-off, custom tank with all our necessary items in the exact place we specified on the pattern. This is the area where Jason designed the recess to clear the fuel lines. This tank is fully baffled and features a tank-mounted Aeromotive A340 Stealth fuel pump. Mounting the pump in the tank as opposed to on the framerail helps keep the pump nice and cool and also provides quiet operation. Also note the vent that Jason had Rock Valley add above the sending unit location.

18. Before the tank is installed under the truck, you can see a number of features that Jason designed into his pattern that Rock Valley transferred into the real deal including the rear notch and the side mounting tabs. The great thing about stainless is that it's nice and strong, has great corrosion resistance, and looks good with little to no maintenance required.