The parts we used differ a bit from what's in the kit, as we had an older version of the early-Mustang package that places the blower on the driver side and uses a Novi 1200 that's not self-lubricated. However, we used the same pulley ratios and PowerHat and have no reason to believe that our results will differ from the new Entry Level package.

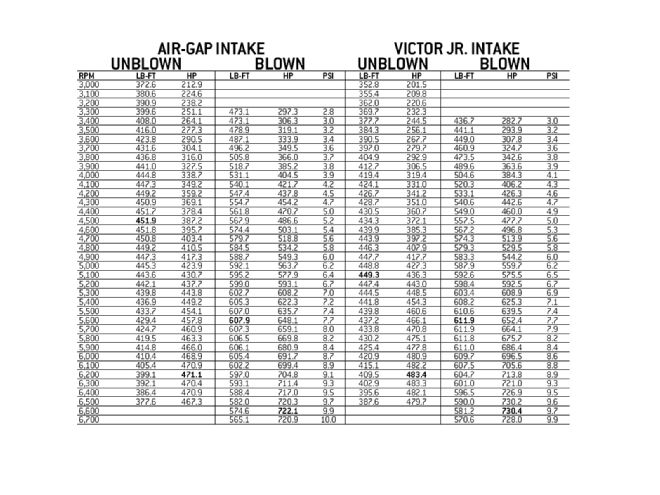

In comparing the dual-plane Air-Gap intake with the single-plane Victor Jr., it was no surprise that, naturally aspirated, the dual-plane tromps below 5,000 rpm and the single-plane takes over at higher rpm. The same effect was seen when the engine was supercharged. The longer runners of the dual-plane blew the doors off the single-plane below 4,000 rpm, making as much as 35 extra lb-ft. The Air-Gap is stronger than the Victor Jr. all the way to 5,200 rpm, but the Victor never gets ahead by more than 10 or 12 hp. Our pick would be the Air-Gap. Paxton developed this kit for mildly hopped-up 289s and 302s and included pulleys estimated to deliver 7 to 8 pounds of boost around 5,500 rpm. Our Dart 363 has more displacement, which tends to reduce the boost reading, but we saw 7.4 psi at 5,500 rpm, right on Paxton's target. Our engine also carried more rpm (up to 6,600) than would be expected of a stock 289. Spinning the blower faster makes more boost, hence we saw 10 psi at 6,700 glorious rpm.

Your other expense will be adding a blower bypass valve. This doohickey relieves blower pressure in circumstances in which the throttle is closed and engine rpm remains high, like when you lift while the trans is still in gear because you've panicked under newfound, brutal acceleration. Without the bypass, pressure can stack up against the blower vanes and cause badness. Paxton's least expensive option is PN 8D204000 ($245.00) and the mounting flange, PN 8D004-052 ($24.00).

The upgrades we just listed add up to $766.90. Add that to the price of a satin blower kit and you've got $3,126.85. That might be the end, or maybe not.

Another cost consideration is whether your existing carburetor is up to these antics. There's a lot of voodoo talk about blow-through carburetors, but we've found that an out-of-the-box Holley with adjustable air bleeds and without a choke tower can be tuned for boost levels up to 8 to 10 psi. Making it even easier is the Paxton PowerHat, which uses a diffusion element to reduce turbulence across the top of the carburetor. We've tested it three times, and we like it.

Then there's ignition timing, which must be retarded to safely run with boost, especially on pump gas. Our 363 made best naturally aspirated power at 36 degrees total lead, but we ran 27 degrees with the blower. The problem is that you can't just crank back the distributor if you have one with mechanical advance, because when you retard the total timing lead at high rpm, you'll reduce it by the same amount at idle. In our case, the change from 36 to 27 degrees retarded the total timing by 9 degrees. If we'd been idling at 15, it would now be 6 degrees, which is not groovy. You'll need to either limit your advance curve or invest in one of the electronic boost-retard boxes or, better, one of the newer boxes with a computer-programmable timing curve. MSD offers both.

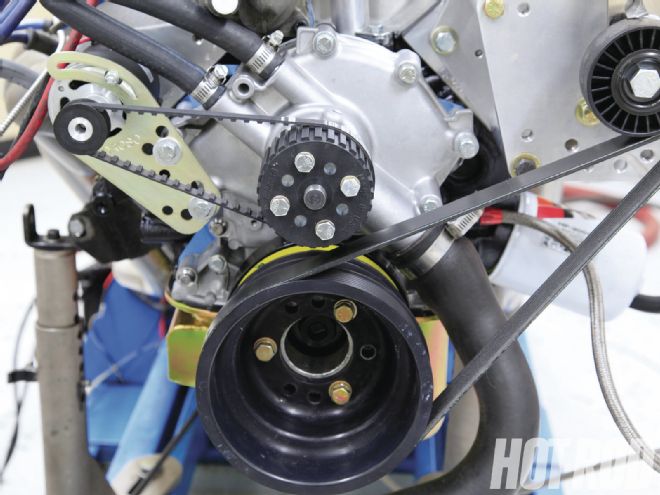

How about your accessory drive? The passenger-side blower mounting creates no problems with a power-steering pump or a driver-side alternator. If you've got anything different, get ready to figure out some new brackets, belts, and pulleys. The last hidden cost is an O2 reader, which we highly recommend. Your carb will need to be jetted up significantly for the added power, and you can't do that without a way to data-log your air/fuel ratio, shooting for about 12.0:1 at WOT.

The kit's pulleys measure 3.7 inches on the blower and 6.88 at the crank for a ratio of 1.86:1. With the blower's internal step-up ratio of 3.54:1, you need to consider the maximum impeller speed of 52,000 rpm if your engine spins to 7,500 rpm. Those pulleys are for an eight-rib, serpentine-style belt. We've sworn off ribbed belts for blowers because they always slip, as ours did, requiring us to crank up the belt tension between pulls to get repeatable results. We ran a higher rpm and more boost than what was intended for this kit, both of which led to slip. A larger blower pulley would reduce boost (and power) and aid belt grip.