If you think about it, headers are a lot like an induction system. As a means of transferring gases, they’re partly responsible for an engine’s behavior. They’re also greatly responsible for an engine’s image: Just as a multitude of carburetors can, a pair of headers will transform an also-ran into a front runner, if only aesthetically.

But headers differ from induction systems in a few critical ways. Whereas nearly any induction system will fit in most applications on its respective engine, headers are very specific to the car. Anyone with the gumption and some simple tools can make them fit anything but these deceptively simple parts have one shortcoming: their construction isn’t so plainly clear.

It is to Rick Carlyle, though. He learned the ropes with exhaust greats like Jerry Jardine and Frank Sanders (S&S). About 20 years ago he formed So Cal Engineering to cater exclusively to the hot rod business. He found immediate praise in the nascent revivalist movement for lakes-style headers that were exact in every way but one: His were near perfect, a consequence of modern budgets.

Though he largely hung it up when he retired, a special request inspired him to make another set. Chick Kozsis asked him to build a set to replace the ones he made for his blown Deuce roadster that got stolen from the host hotel’s parking lot at this year’s Grand National Roadster Show.

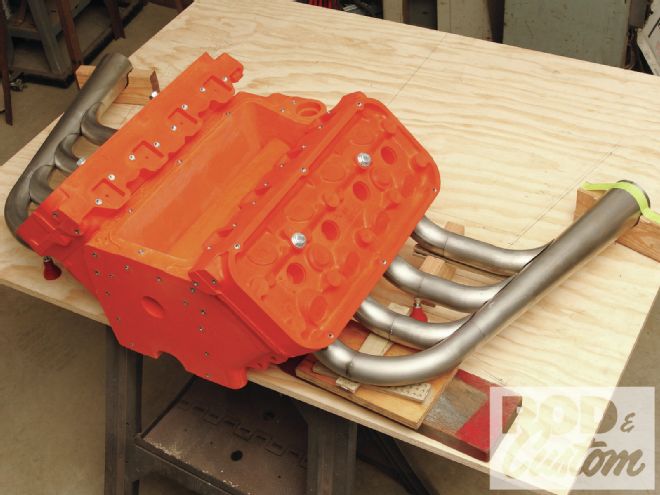

1. For these remote jobs, Rick Carlyle builds a fixture based upon the owner’s cowl and chassis dimensions. It’s not a bad idea even if the car is available if only because it raises the work height and offers a means to fixture the tubes so each side matches the other.

1. For these remote jobs, Rick Carlyle builds a fixture based upon the owner’s cowl and chassis dimensions. It’s not a bad idea even if the car is available if only because it raises the work height and offers a means to fixture the tubes so each side matches the other.

Carlyle has shown how he builds headers before but never to the extent that he did this time. Among the things he revealed was a very clever, if not unique, means to build them. You see, although Kozsis and Carlyle both live just a few miles from the border, they’re two different countries (Carlyle can see Canada from his kitchen). He mounted a mock-up Hemi block on a plywood board marked with the engine position and cowl and frame dimensions that Kozsis provided. It’s a system based on the one he used to build the headers for Royce Glader’s AMBR-contending roadster pickup, among others.

Carlyle favors lakes-type headers, specifically ones with big, curvy bends. The prevailing multi-tube, merge-type header design is touted to be more efficient than the lakes design because it can develop spontaneous low-pressure conditions after each exhaust valve shuts. But just because it can doesn’t always mean it does. In fact most off-the-shelf header designs generate little if any low-pressure conditions at all. So just because a lakes-style header is theoretically less efficient on paper doesn’t mean it’ll perform any poorer on the street. In fact, blown engines don’t benefit from the low-pressure effect at all, a trait that justifies zoomie-type headers on dragsters.

Engine parameters dictate pipe diameter but wall thickness is entirely up to you (although Carlyle suggests 16 gauge). He recommends delivering exhaust to the cone in sweeping bends primarily for aesthetic reasons, but it’s reasonable to assume the exhaust flows better than it would if delivered at a blunt angle.

2. He begins at the source of the exhaust, the flanges that bolt to the heads. He also emphasizes quality for fit and thickness for leak-free performance. These measure 3/8-inch thick.

2. He begins at the source of the exhaust, the flanges that bolt to the heads. He also emphasizes quality for fit and thickness for leak-free performance. These measure 3/8-inch thick.

He also suggests using mandrel-bent tubing. It maintains its cross-section, which improves performance. But more than that, the consistent cross-section means tubes can be cut anywhere along the bend and match others perfectly so long as the cuts are made along the bend’s radius. The crush-bending process, on the other hand, mashes the tube into an oval that matches nothing.

This construction is open to several welding processes. Of course GTAW (TIG) requires the least finishing, which is why Carlyle favors it. But GMAW (MIG) and FCAW (flux-core) will indeed suffice, provided you don’t mind ropy beads or lots of grinding. But there’s an even more appealing option: The flanges withstanding (which work best with GTAW and almost as well with GMAW), this is an application practically made for oxyacetylene welding.

18. After marking the interferences Carlyle removes the pipes and sands them. Note that he uses every part of the belt, like around the wheels and over the edges of the belt (as seen here).

18. After marking the interferences Carlyle removes the pipes and sands them. Note that he uses every part of the belt, like around the wheels and over the edges of the belt (as seen here).

Acetylene welding is appealing because it produces weld beads barely harder than the base metal. That’s good because soft materials move readily. And whether by heat cycling or engine vibration the metal in headers moves quite a bit. The boundary between the soft pipes and relatively hard electric weld beads concentrate stresses that often cause the metal to crack adjacent to the weld. Gas can produce beautiful, small welds but it just takes more practice.

We’ll also expand upon another piece of advice in the captions but here it is in a nutshell: start with the side that has the rearmost-offset cylinder bank. One bank of a V-configured engine sits slightly behind the other. With a few exceptions (big Olds, Poncho, and the late OHV Caddy for examples), this means the passenger side, and on some engines, the offset is huge (roughly 3 inches for big Chevys).

19. Making the entire tube fit the cone perfectly isn’t ideal because the angle between the primary and the cone is less than 90 degrees. Instead, Carlyle fits the “heel” perfectly and lets the “toe” run long and curl away from the cone (as seen here).

19. Making the entire tube fit the cone perfectly isn’t ideal because the angle between the primary and the cone is less than 90 degrees. Instead, Carlyle fits the “heel” perfectly and lets the “toe” run long and curl away from the cone (as seen here).

Doing so establishes the forward-most position where the header ends. Start there and you can lengthen the other side’s header to match; however, if you start on the forward-offset side you may not be able to shorten the rearmost offset header to match.

Beyond that, though, the world is your canvas: primary pipe angle and length, cone angle and length, and construction style are open to your interpretation. As Carlyle worked he explained how fit and style largely prevail in lakes header design. Get a grasp of those and a mastery of some simple tools and you’re guaranteed a header that’s unique, just like your car.

The final product is not just functional, it’s quite beautiful. And if Kozsis measured right, they’ll fit as if Carlyle built ’em on the car.

The final product is not just functional, it’s quite beautiful. And if Kozsis measured right, they’ll fit as if Carlyle built ’em on the car.