Ever heard the saying, "You can't have your cake, and eat it too." In car speak that translates into, "If you want a lot of power, you will have to sacrifice drivability and fuel economy." Granted, most diehard Mopar fans are used to the trade-off, and refuse to give up horsepower for pretty much anything. We've simply learned to cope with all the various drivability issues associated with vintage high performance powerplants. There may even be a little pride connected with how "radical" an engine you are able to manage on the street.

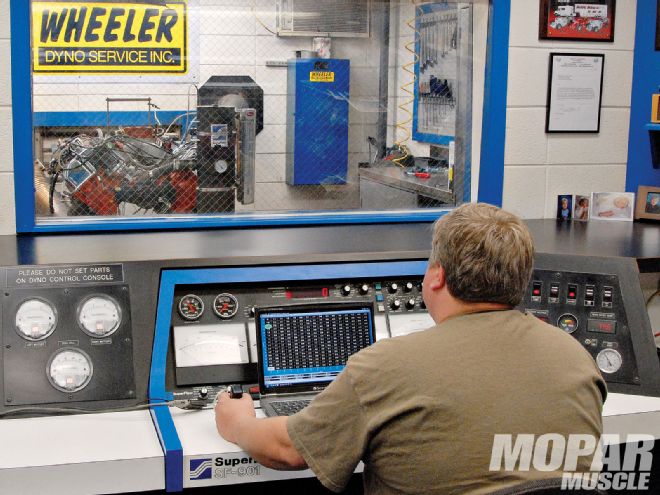

Wheeler Dyno Services Jeff Fiala broke in our crate Hemi with a stock dual plane manifold and a Holley 750 so we would be sure to have a clean break in run and also so we would have some base power figures to compare to the XFI system.

Wheeler Dyno Services Jeff Fiala broke in our crate Hemi with a stock dual plane manifold and a Holley 750 so we would be sure to have a clean break in run and also so we would have some base power figures to compare to the XFI system.

But unless you have been living under a rock for the last few years, you've noticed that Chrysler is producing some pretty hot engines that not only rival the vintage iron for power, they also pass emissions, get decent fuel economy, and run smooth enough that your grandma can take it to church on Sunday and not think that it's anything special.

How are they doing it? Well, you know this too. It's no secret. It's computer-controlled, electronic fuel injection. Certainly there have been other advancements in engine design, but they all work because the computer can precisely control fuel and timing (and a whole lot of other things in the car) at every engine speed, load condition, and temperature.

So what do you suppose it would be like to drive a 500 horsepower big-block that doesn't have any flat spots in the power curve, never loads up in traffic, and always starts quickly, runs the same whether it's hot or cold out, and gets double digit fuel economy? We thought we'd find out if we can have the proverbial cake and enjoy the frosting too.

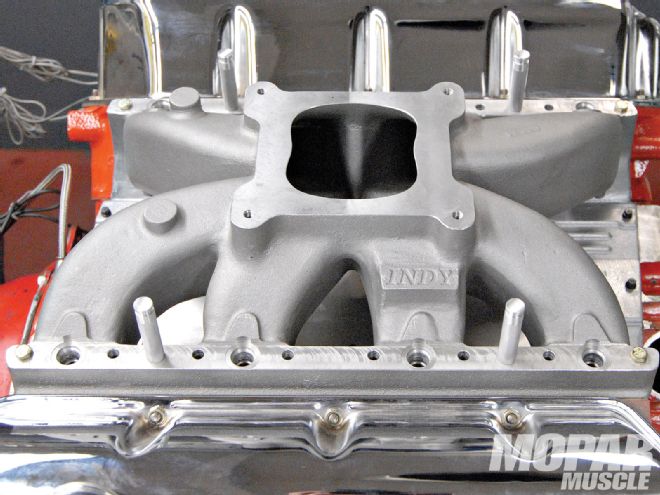

As far as the FAST parts, this is what you'll need to convert your vintage iron into a modern and at least a more efficient fuel injected engine. Included is a FAST dual-sync distributor, the XFI ECU, 42-lb/hr injectors, a one bar MAP sensor, a throttle position sensor, an idle air control motor, air and water temp sensors, a wide band (9-1 to 16-1 A/F ratio) oxygen sensor, and of course a throttle body. You'll also need to either have your intake modified for injectors, or get one already done like the single plane we used from Indy Cylinder Head.

As far as the FAST parts, this is what you'll need to convert your vintage iron into a modern and at least a more efficient fuel injected engine. Included is a FAST dual-sync distributor, the XFI ECU, 42-lb/hr injectors, a one bar MAP sensor, a throttle position sensor, an idle air control motor, air and water temp sensors, a wide band (9-1 to 16-1 A/F ratio) oxygen sensor, and of course a throttle body. You'll also need to either have your intake modified for injectors, or get one already done like the single plane we used from Indy Cylinder Head.

Our test vehicle is a '68 Hemi Dart replica that's being built at Muscle Car Restorations in Chippewa Falls, WI. The owner doesn't just want a really cool car, he also wants hassle free driving-to be able to get in it and go any distance under any condition. While there are a number of quality EFI products on the market, for this test we will be working with a FAST (Fuel Air Spark Technology) system. The FAST system is extremely flexible and can handle virtually any combination you can dream up. All you need to do is let them know which engine you're running, the approximate power level you expect, and what ignition system you will be using, and they can set you up with everything you need.

In this case, that includes the FAST ECU, a FAST dual-sync distributor, a throttle body, a set of 42-lb/hr injectors, and the wiring harness to tie it all together. There is also an idle-air control motor, a MAP sensor, a wide band O2 sensor, a throttle position sensor, and air and water temp sensors. Of course you need a place to fit the injectors so an Indy single-plane intake and valley cover will also be used (though your stock intake could be fitted for injectors if you'd like). FAST also includes their C-Com EFI Software and a rather in-depth training DVD.

The Indy single plane comes ready to receive the injectors and fuel rail, making them both a simple bolt-on affair.

The Indy single plane comes ready to receive the injectors and fuel rail, making them both a simple bolt-on affair.

Our engine is a Hemi crate motor that will be used in its stock configuration except for the Indy intake manifold. But before we hooked up the EFI, we broke the engine in with a stock intake and a 750 Holley so that we could both be assured of a clean break in run, and provide some base dyno numbers we could use for comparison after the EFI install. Box stock, our Hemi made a 482 horsepower and 469 lb/ft of torque.

Once the Hemi cooled down, we swapped intakes and hooked everything up. It really couldn't be much easier. Everything is a simple bolt on with the exception of the O2 sensor. You'll need to weld a bung onto one of your header collectors in order to mount it. Connecting all of the wiring is also easy because all of the connections are clearly marked. It's truly plug and play.

One upgrade you will need to make, though, is to an EFI compatible fuel system. You'll need a pump capable of providing the volume of fuel necessary for your power level and can also maintain the proper fuel pressure (normally 45 psi) at the injectors. A bypass regulator and return fuel line will also be necessary. The guys at FAST can help you with parts selection if you are not sure.

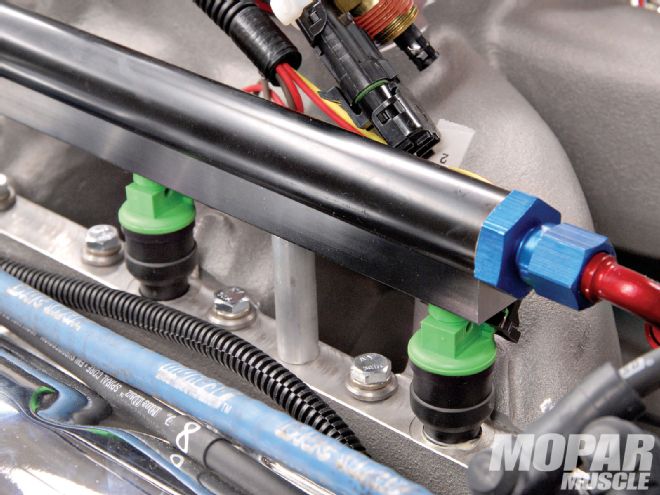

The injectors simply push into the intake bosses and are held in place by the fuel rail. Lube the O-rings with a little white lithium. FAST recommended 42-lb/hr injectors (rated at 45 psi), which are good for up to about 650 horsepower. Injector size is fairly critical to overall performance. Too small, and you'll limit power and risk going lean. Too big gains you nothing on the top end but will likely cause idle and low speed issues. Jeff recommends that your injector duty-cycle at max power be no more than about 80 percent (our Hemi was at 70) and the duty cycle at idle be no lower than about 21/2 percent. That way you have room for the XFI system to protect against any lean conditions that might occur and you'll have fine enough control on the low end for good idle and low speed operation. Jeff has also found that a vacuum referenced fuel pressure regulator will help make a little oversized injector appear smaller, run better, and be easier to tune down low.

The injectors simply push into the intake bosses and are held in place by the fuel rail. Lube the O-rings with a little white lithium. FAST recommended 42-lb/hr injectors (rated at 45 psi), which are good for up to about 650 horsepower. Injector size is fairly critical to overall performance. Too small, and you'll limit power and risk going lean. Too big gains you nothing on the top end but will likely cause idle and low speed issues. Jeff recommends that your injector duty-cycle at max power be no more than about 80 percent (our Hemi was at 70) and the duty cycle at idle be no lower than about 21/2 percent. That way you have room for the XFI system to protect against any lean conditions that might occur and you'll have fine enough control on the low end for good idle and low speed operation. Jeff has also found that a vacuum referenced fuel pressure regulator will help make a little oversized injector appear smaller, run better, and be easier to tune down low.

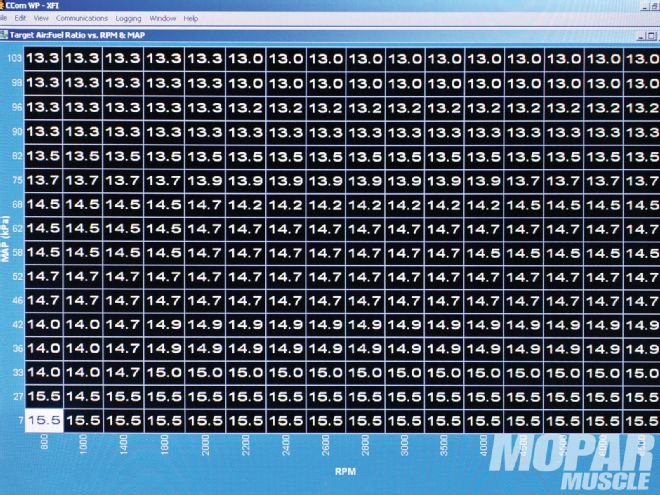

Programming the software is what usually scares most people away from EFI, and while FAST's C-Com XFI software has a large amount of capability built into it, once you start to break it down into its individual components, you'll be able to logically move through the system and you'll likely be amazed at the amount of control that you have. If you can tune a carb and a distributor and know how to read your plugs, you'll do fine with this software. If there is a trick to it, it's knowing what your engine needs in terms of fuel and timing throughout its rpm and load range.

At the heart of the software are three tables or "maps" that control the amount of fuel delivered at every rpm and load, the amount of timing needed at a given rpm and load, and a target air/fuel ratio table. In each case, the load level is represented on the vertical scale and rpm on the horizontal scale. Knowing how to initially set up each of these will put you well on your way to setting up your tune. Fortunately, FAST has a number of base maps to help you get started. It's really not any different from tuning a carburetor and a distributor; you need to know that you have safe timing and air/fuel ratios at the start so you don't damage your engine on the first pull. It's been said that you can be rich all day but you can only be lean once. That's good advice.

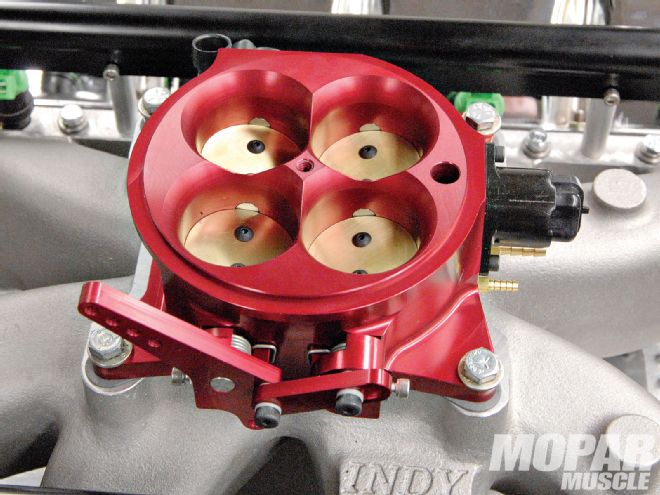

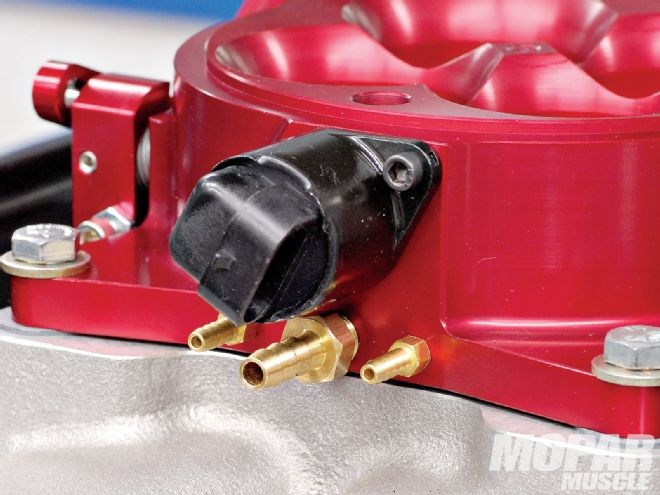

This FAST throttle body works much like a carb except, of course, that it's dry, flowing only air. This is one of the major advantages of fuel injection. Because the intake only flows air, you won't have any of the fuel distribution problems that you can have with a carburetor. The FAST system even allows you to tune the A/F ratio (and timing) for individual cylinders.

This FAST throttle body works much like a carb except, of course, that it's dry, flowing only air. This is one of the major advantages of fuel injection. Because the intake only flows air, you won't have any of the fuel distribution problems that you can have with a carburetor. The FAST system even allows you to tune the A/F ratio (and timing) for individual cylinders.

There are basically three ways you can tune your FAST equipped engine: on an engine dyno, on a chassis dyno, or on the street. An engine dyno will probably allow the most accurate tune as you'll have complete control over rpm and load conditions, and you can easily measure the results of any changes that you make. However, cold start, cold run, and accelerator enrichment settings may need to be tweaked some once you are on the road.

A chassis dyno is a real good place to put the finishing touches on an engine dyno tune, but it also works well by itself. If you are installing EFI on an engine that is already in the car, then this is the way to go. You'll be able to simulate real world driving conditions while closely monitoring your engine. You still may have cold start and run tuning to do because you need the basic engine tune in place first and it's unlikely you'll be able to let your car sit on the dyno long enough for your engine to go stone cold again.

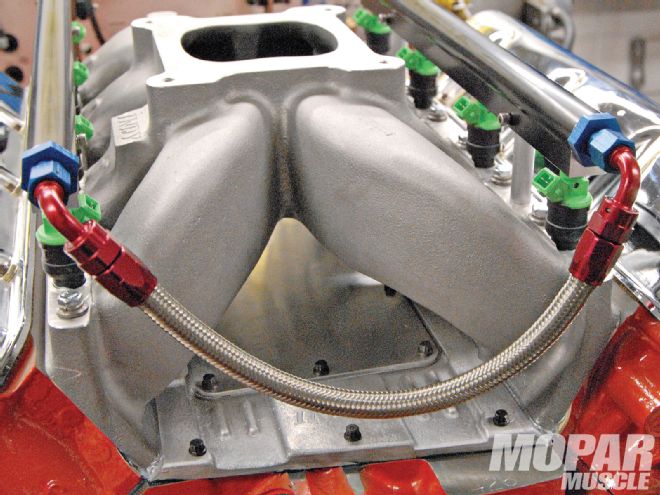

Once you have the injectors and fuel rails in place, you'll need to connect them. We did it with some braided line. A -8 to -6 reducer is first O-ringed into the rail followed by a -6 90 degree elbow. Be prepared to fit your own line per your application. The opposite ends of the rails will be connected for fuel in and fuel return.

Once you have the injectors and fuel rails in place, you'll need to connect them. We did it with some braided line. A -8 to -6 reducer is first O-ringed into the rail followed by a -6 90 degree elbow. Be prepared to fit your own line per your application. The opposite ends of the rails will be connected for fuel in and fuel return.

Based on their experience (and probably that of your dyno operator) FAST will be able to help you get these types of settings close enough to get you out cruising.

Tuning on the street can be done, but you'll need a lot of patience and a buddy to watch the engine condition on your laptop. Running your engine through all possible rpm and load conditions is going to be problematic since there is no way to safely and legally make full power runs. Also, street tuning by itself is just not the way to get the most out of your EFI investment because there is no direct way to measure any changes you make. An hour's worth of time on a chassis dyno will pay instant dividends.

On the back of the throttle body is the idle-air control motor or IAC. It provides and controls the amount of air needed to maintain the idle speed that is set into the ECU. Below it are three vacuum ports. The center will supply the power brake booster. The right hand one is for the MAP sensor. The left is unused for this application.

On the back of the throttle body is the idle-air control motor or IAC. It provides and controls the amount of air needed to maintain the idle speed that is set into the ECU. Below it are three vacuum ports. The center will supply the power brake booster. The right hand one is for the MAP sensor. The left is unused for this application.

However you decide to tune your engine, you'll greatly benefit from becoming familiar with the software's data logger feature. Once activated, it will record all of the sensor data so that you can go back over an entire dyno pull and see moment by moment the information that's coming from up to fourteen different sensors. Essentially, you can "relive" any period of engine time in slow motion.

Now, if you are looking for massive power gains with EFI, you'll not be real happy with the results. A properly tuned carburetor will pretty much match what an EFI system will produce in terms of peak power output. But because you'll have very precise control over fuel and timing, you will be able to push the limits closer to the edge and maybe run a little more compression, a little more timing, and maybe a little leaner than otherwise would be safe. You will see improvements in part throttle operation and probably also in the lower end of the power band because, again, you will be able to control the fuel and spark much more exactly than you could ever even think of with a carb and a distributor.

Normally, the air temp sensor would be located inside the air cleaner, but on an engine dyno, it's ok to simply secure it somewhere near the throttle body.

Normally, the air temp sensor would be located inside the air cleaner, but on an engine dyno, it's ok to simply secure it somewhere near the throttle body.

Another benefit is the ability to record and switch between more than one tune. You can optimize one set of maps for general cruising on pump gas, and another set for when you are feeling frisky and want to dump in some C16 and go racing. You should also be more consistent since the XFI system constantly adjusts the fuel for differing temperature and weather conditions. No more needing to change jets because it's cooling down at the end of the day. And if you run the data logger, you can go back and see exactly what your engine was doing during the entire run. The XFI system is also very adept at handling blowers, turbos, and/or nitrous applications. Just give the guys at FAST a call, tell them about your dream engine, and they'll set you up.

Because an engine dyno can hold an engine at any particular load and RPM, it allows Jeff to systematically go through the engine's entire operational range to optimize both A/F ratio and timing for any condition the engine will ever see. Once this is done, Jeff can then move on to accelerator enrichment settings. But in order to properly set the cold start and run parameters, the engine needs to return to stone cold again. If you can't leave your engine on the dyno that long, these items are easily tweaked in the car. We picked up about 20 hp on the top end with a max of 503 hp at 6200 rpm, and we lost about 15-20 hp down low but this is about what you might expect from switching from a dual to a single plane manifold.

Because an engine dyno can hold an engine at any particular load and RPM, it allows Jeff to systematically go through the engine's entire operational range to optimize both A/F ratio and timing for any condition the engine will ever see. Once this is done, Jeff can then move on to accelerator enrichment settings. But in order to properly set the cold start and run parameters, the engine needs to return to stone cold again. If you can't leave your engine on the dyno that long, these items are easily tweaked in the car. We picked up about 20 hp on the top end with a max of 503 hp at 6200 rpm, and we lost about 15-20 hp down low but this is about what you might expect from switching from a dual to a single plane manifold.

In the Air/Fuel Ratio table, you have to tell the ECU what A/F ratio you want your engine to hold at every rpm and load that it could ever see. The program will compare these numbers to the actual A/F ratio as measured by the wide-band O2 sensor and will add or subtract fuel to make the actual A/F ratio match this table, at least within the correction limits that you have set. What's critical here is that you know what these numbers need to be for your engine. You'll likely tweak them some during your dyno session as you are looking for max power, crisp part-throttle cruising, and a clean idle, but you must start with some safe ratios that are at least close. In a lot of scenarios, the folks at FAST can set you up with good starting base tables that your dyno operator can massage to his liking. There are also independent tuners out there that will provide you with tables based on their experience with similar engines. In the end, though, accurately reading your plugs is still the best way to know what your engine needs.

Crate Hemi With 750 Holley

RPMTorqueHP

3,500456304

4,000453345

4,500467400

5,000470454

5,500447468

6,000422482

Hemi With FAST EFI

RPMTorqueHP

3,500419279

4,000430328

4,500482413

4,700485434

5,000474451

5,500452474

6,000438500

Crate Hemi With 750 Holley

RPMTorqueHP

3,500456304

4,000453345

4,500467400

5,000470454

5,500447468

6,000422482

Hemi With FAST EFI

RPMTorqueHP

3,500419279

4,000430328

4,500482413

4,700485434

5,000474451

5,500452474

6,000438500