In the February '98 issue, we detailed the construction of a long-rod, high-compression Ford 351W V-8. Since this was a street-only engine, we purposely set our engineering goals very high. We required full emissions compliance, a factory-quality idle, and the inclusion of the Ford EEC-IV factory fuel-injection system to produce at least 400 hp and 400 lb-ft of torque. Further, we wanted to achieve peak power at 5,000 rpm and peak torque at 4,000 rpm. To all of you who anticipated the appearance of Part Two sooner, we extend sincere apologies. Considering the results, we think you'll find that the wait was worthwhile.

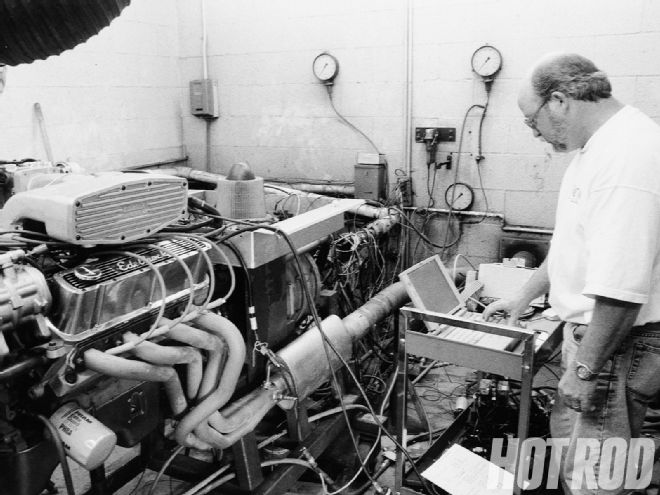

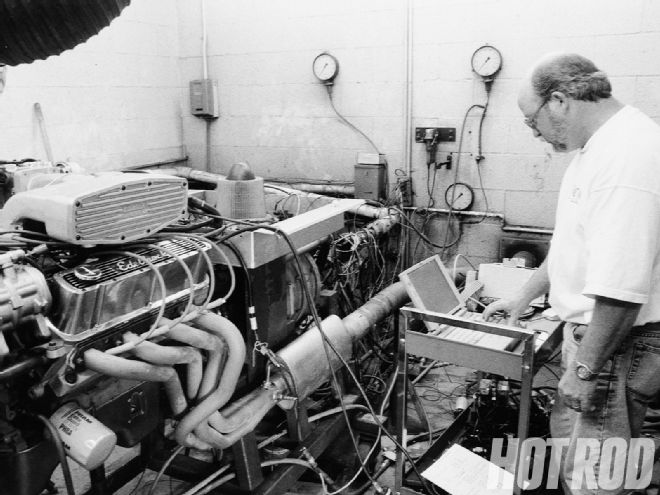

Our 351W is emissions compliant, sports 11:1 compression, runs on 87-octane unleaded, and can be built by any hot rodder in his home garage. Ken Christley of Kenne-Bell checks the A/F ratio as delivered by the company's computer chip.

Our 351W is emissions compliant, sports 11:1 compression, runs on 87-octane unleaded, and can be built by any hot rodder in his home garage. Ken Christley of Kenne-Bell checks the A/F ratio as delivered by the company's computer chip.

Parts and Design

The basic engine theory and its components are detailed in the first installment of this two-part article, but we'll briefly restate the concept here. The key to our engine is unusually long (6.58-inch) connecting rods, 11.0:1 static-compression ratio, optimized fuel delivery and spark timing, and a wise selection and matching of the primary parts (see list). In a nutshell, longer rods allow the engine to make more power and to reduce its breathing needs, as well as its sensitivity to detonation, thereby allowing a relatively high static-compression ratio. A higher compression ratio elevates power and torque, and the reduced breathing relies on the long connecting rods to work better with OEM-type, air-limited intake systems and yield more go at low rpm levels.

The Problem with Factory Fuel Injection

The OE fuel injection posed three major engineering challenges: air, spark, and fuel delivery. First, let's look at providing optimum fuel delivery throughout the rpm band during wide-open throttle (WOT) and balancing it with the right amount of spark timing. Though the Ford EEC-IV mass-air SEFI system is very adaptable, in stock form it cannot make the substantial changes necessary to provide the optimum air/fuel ratio for a 400hp engine such as ours. Further, the EEC-IV system's WOT preprogrammed spark curve is non-adaptable. Without addressing these challenges, our highly modified 351W wouldn't perform at full potential with stock EFI.

Offsetting the wristpins 0.090 inch yields a slight angle to the rod when the crank is at top dead center (TDC); this effectively eliminates the deadlock between the two as the piston starts to push downward. This small amount of rod angle at TDC helps push the crank over more easily and should add low rpm power and torque. The penalty is a little more cold-start piston noise, but there is no increase in cylinder-wall wear.

Offsetting the wristpins 0.090 inch yields a slight angle to the rod when the crank is at top dead center (TDC); this effectively eliminates the deadlock between the two as the piston starts to push downward. This small amount of rod angle at TDC helps push the crank over more easily and should add low rpm power and torque. The penalty is a little more cold-start piston noise, but there is no increase in cylinder-wall wear.

We found part of the solution at Kenne-Bell, in Rancho Cucamonga, California. The company supplied one of the few aftermarket chips available that can make the kinds of WOT fuel- and spark-timing changes needed by this offbeat engine combination. Traditionally, you couldn't attain these factors with "black box" factory EFI systems, but Kenne-Bell got into the factory computer and modified the WOT spark and the injector pulse control curves to deliver exactly what the motor needed. Since the company was involved in the development of this engine, it can supply the same chip we used.

In the matter of air delivery, even some aftermarket fuel-injection manifolds cannot pass the same amount of air that a good dual-plane carburetor manifold can deliver. To make matters worse, (according to engine-wizard Ken Duttweiler) the Ford 351W doesn't breathe as well as the Chevy 350, even in carbureted trim. Knowing this beforehand prompted us to enhance intake breathing from the start. Extrude-Honing the Edelbrock intake manifold, a 75mm throttle body, and an 85mm mass-air meter were all part of the path to power.

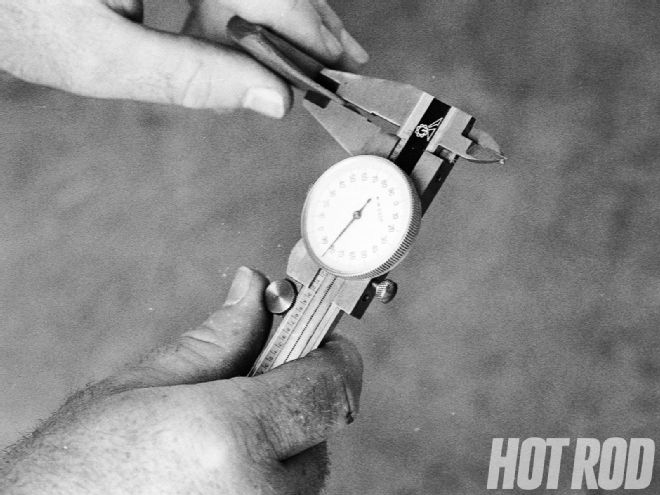

We double-checked piston-to-valve clearance by putting clay on top of the pistons during the mock-up process and rotating the engine through a couple of cycles. Our design yields 0.125-inch clearance on the intake side, 0.235-inch clearance on the exhaust side, and about 0.055-inch squish clearance between the flat portion of the piston and the bottom of the heads. The small squish clearance (being measured here) improves combustion-chamber efficiency.

We double-checked piston-to-valve clearance by putting clay on top of the pistons during the mock-up process and rotating the engine through a couple of cycles. Our design yields 0.125-inch clearance on the intake side, 0.235-inch clearance on the exhaust side, and about 0.055-inch squish clearance between the flat portion of the piston and the bottom of the heads. The small squish clearance (being measured here) improves combustion-chamber efficiency.

Cylinder Heads

We tested with two different sets of heads on our long-rod 351W. The regular TFS Twisted-Wedge small-block heads flow 250 cfm of air, as determined by our own flow-bench testing at Duttweiler's. Although this is a good number, we also dyno-tested our prodigious 351W with the TFS "R" head, which passed a whopping 290 cfm. Normally, such a "large" head would give up tons of low rpm torque, but by using long rods, the normal way of thinking doesn't apply anymore. In fact, the bigger heads produced 20 hp more at the 5,000rpm peak and 20-plus lb-ft of additional torque at 4,000 rpm. In our analysis, the bigger heads could support a slightly longer camshaft with 4 to 5 degrees more duration. This would take a small amount of torque away from the 2,000- to 3,500rpm band, but it would add torque and power from 4,000 rpm and up.

Dyno Results

The 250cfm heads made 380 hp and 430 lb-ft of torque. The increased flow of the 290cfm heads made 400 hp and a 450 lb-ft of torque-these numbers are comparable to the best big-cube engines of the '60s musclecar era! When you consider that this was done using the Ford EEC-IV fuel-injection system with all its emissions strategies, 87-octane gasoline, a hydraulic roller cam that is but 10 degrees longer than a stock 5.0L late-model Mustang cam, and that the engine is emissions-legal, the results are all the more impressive.

Summary All in all, our long-rod SEFI 351W engine hit a grand slam, dispelling the notion that fuel injection offers good, cold start-up and driveability features, clean emissions, and respectable fuel mileage, yet it just can't keep up with a carburetor for power. We proved quite the opposite. Even with a good dual-plane intake and a streetable four-barrel carb, our 351W would have made about the same hp and would not have come close to the torque figure. By comparison, the hugely successful long-rod Chevy 352 we built for the June '97 issue made 413 hp and 430 lb-ft of torque in carbureted trim.

If you match the parts and assembly methods we used with our long-rod 351W, you can achieve the same power and torque figures. Since acceleration on the street is largely a function of torque, putting this anaconda under the hood of any car should result in the kinds of thrills and neck-snapping fun that only the musclecar era could deliver from a small-block-until now!

Dyno Results of 351W with TFS R Heads Engine rpm Torque Horsepower 2,500 367 175 2,600 377 187 2,700 385 198 2,800 383 204 2,900 382 213 3,000 386 220 3,100 394 234 3,200 391 238 3,300 419 263 3,400 416 269 3,500 428 285 3,600 431 295 3,700 435 307 3,800 436 315 3,900 455 338 4,000 458 349 4,100 449 350 4,200 453 362 4,300 455 372 4,400 449 376 4,500 443 380 4,600 440 386 4,700 436 390 4,800 433 396 4,900 427 399 5,000 421 401 5,100 411 400 5,200 400 396 5,300 382 385 5,400 367 378 5,500 351 367

Dyno results prove the value of long rods and show that with the right combination of parts and calibration, factory EFI can match a carburetor for power. A heavy vehicle or one equipped with an automatic transmission requires a lot of low-rpm torque to provide neck-snapping acceleration. It is clear that our long-rod 351W is an ideal candidate for this. The torque curve is bountiful and fat, which means the engine will be very tractable on the street.

Effects of Restricted Inlet Air with Standard

Heads

Small

Intake Tube

Large

Intake Tube

Engine rpm

Torque

Horsepower

Torque

Horsepower

2,500

378

180

379

180

2,600

384

190

386

191

2,700

401

206

400

205

2,800

416

222

419

225

2,900

412

228

414

230

3,000

409

234

409

234

3,100

406

240

406

240

3,200

406

247

405

246

3,300

422

265

422

265

3,400

427

276

427

276

3,500

426

284

426

285

3,600

422

289

421

289

3,700

419

295

419

294

3,800

422

305

420

303

3,900

425

316

425

315

4,000

427

325

427

325

4,100

428

334

428

335

4,200

431

344

431

344

4,300

428

350

430

352

4,400

423

354

425

358

4,500

415

355

422

361

4,600

410

358

418

366

4,700

403

361

414

371

4,800

396

362

409

374

4,900

390

364

405

378

5,000

384

365

400

380

5,100

376

365

389

378

5,200

365

362

376

373

5,300

354

357

363

366

5,400

342

351

349

358

5,500

322

339

328

345

These curves clearly demonstrate how sensitive the 351W engine is to intake breathing. The universal replacement air-inlet tube stocked by Ford cut the peak power by more than 15 hp, even with the small heads. Switching to an original '86 Mustang tube boosted power significantly and didn't hurt torque at all. With further improvements to intake breathing, the small-head version of our 351W could undoubtedly surpass 400 hp, though we imagine torque would max out at around 430 lb-ft.

Long-Block Parts Part Description Source Block: Stock two-bolt 351W, bored 0.030-inch oversize Local Crank: Stock 351W crank modified for long rods Wayne's Engines Rods: Ford 400-cid modified for 0.866-inch floating pins and 351W crank, with ARP rod bolts Wayne's Engines Bearings: 0.010-inch oversize main (PN MS-1432), 0.030-inch oversize rod bearings (PN CB-927) AE Clevite Pistons: 415-gram dished forging with 0.866-inch pin (PN 139105) JE Pistons Rings: Pregapped 0.030-inch oversize moly (PN R-9902) Speed-Pro (Dana) Gaskets: Overhaul kit with no-retorque head gasket (KS2329) Fel-Pro Cam and lifters: Hydraulic roller cam, 220-degree duration (PN 444131), hydraulic retrofit roller lifters (PN 36532) Crane Cams Pushrods: 7.635-inch hardened steel for standard head (PN 11636), 7.335-inch hardened steel for R head (PN27638) Crane Cams Rockers: 1.7:1 aluminum needle bearing rollers (PN 36757) Crane Cams Rocker studs: 7/16-inch 20 top, 7/16-inch 14 bottom screw-in (PN 99151) Crane Cams Oil pump: High-volume (PN 224-102R ) Speed-Pro Heads: Twisted Wedge, 2.02-inch/1.60-inch valves (PN TFS-51400002), Twisted Wedge R head, 2.080-inch/1.60-inch valves (PN TFS-52400002) milled 0.070-inch Summit Racing Intake: Extrude-Honed (290 cfm per runner) Edelbrock Performer (upper); 351W truck lower; two GGK Phenolic spacers Edelbrock

The entire long-block can be assembled for about $3,000 if you use the standard Summit TFS Twisted-Wedge head. The basic long-block price increases to about $3,800 if you opt for the "R" heads. Compared to what you have to pay for a carbureted crate engine, this is still pretty inexpensive, considering the power and torque the 351W can deliver with fuel injection in a fully emissions-compliant form.

Fuel and Spark Delivery at WOT Engine rpm Total Ignition Timing (degrees) Injector Pulse Percentage 2,500 26.5 81.5 2,750 27.5 85.0 3,000 28.0 86.5 3,250 28.0 88.0 3,500 29.5 89.0 3,750 29.5 90.5 4,000 29.5 91.5 4,250 30.0 92.0 4,500 30.0 92.0 4,750 31.0 91.5 5,000 31.5 91.0 5,250 32.0 89.0 5,500 32.0 87.0 5,750 32.5 83.5

All other things being equal, the less timing an engine needs to make maximum power, the more efficient the combustion chambers are. Our engine only needed 32 degrees of total timing to produce maximum power. By comparison, most old-technology small-block Fords (and Chevys) need 35 to 40 degrees of total timing; again a measure of how efficient our long rods and optimized combustion chambers are.