Hollywood Hot Rod’s Kyle Connole strings the Painless Performance wires in the 2012 AMSOIL/STREET RODDER Road Tour ’40 Ford coupe.

Hollywood Hot Rod’s Kyle Connole strings the Painless Performance wires in the 2012 AMSOIL/STREET RODDER Road Tour ’40 Ford coupe.

For most street rodders the mechanical aspects of our vehicles are easy to understand; they can be seen, held, even heard. The same can’t always be said for electricity; it’s not something you can point to and say “There it is.” But while the concept of electricity may be difficult to grasp, anyone who has made contact with the business end of a spark plug wire with an engine running will testify to its existence.

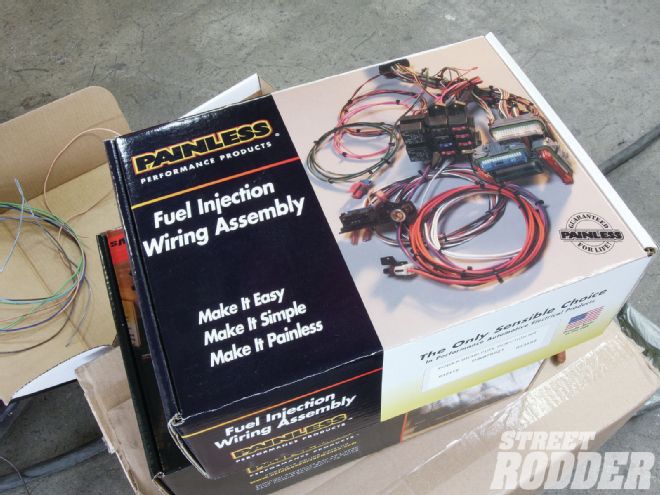

Along with the chassis, for future updates we used a Painless fuel-injection wiring harness to make the Coyote-powered ’40 run.

Along with the chassis, for future updates we used a Painless fuel-injection wiring harness to make the Coyote-powered ’40 run.

Selecting a Wiring Kit

When shopping for a wiring harness there are a number of things to consider. There are two basic types of wiring kits being offered: one has the wires running from the loads and they are then connected to the fuse panel. The other comes with all the wires attached to the fuse block and they are run to the loads where they are connected. For the 2012 AMSOIL/STREET RODDER Road Tour car we chose a Painless Performance kit, which is the later style.

Number of Circuits

Another consideration is the number of electrical circuits needed. In some cases, such as a T-bucket, few circuits are required. However, if a long list of electrically operated comfort items will be included more circuits are necessary. It never hurts to plan ahead. If your rod doesn’t have air conditioning but you plan on installing it later, choose a harness that has the necessary circuit kit.

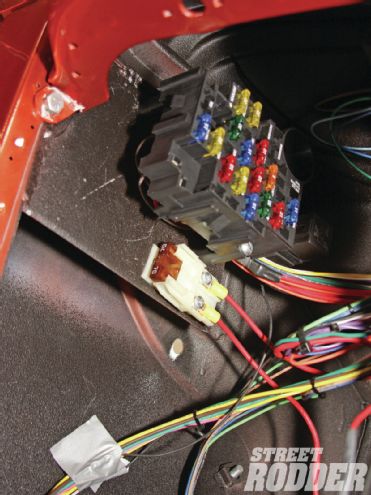

It’s nice to tuck fuse panels out of sight, but they should be easy to access. Note the maxi fuse below the panel.

It’s nice to tuck fuse panels out of sight, but they should be easy to access. Note the maxi fuse below the panel.

Number of Connections

Typically electrical system problems are the result of bad connections. The more connections that are made by the harness manufacturer the fewer there are to cause problems.

Follow the Instructions

The crew who built your harness has heard about every conceivable problem and has gone to great lengths to prevent them. Do yourself a favor and read the instructions completely before beginning the installation.

A look at electrical system components and a few tips

By: Dennis Overholser/painless Performance

Maxi Fuse

Maxi fuses are the latest in overall circuit protection. They replace the old fusible link, which can be restrictive in current flow, and the Maxi fuse is also easier to replace, if necessary. Like most other fuses, they come in many amperage ratings.

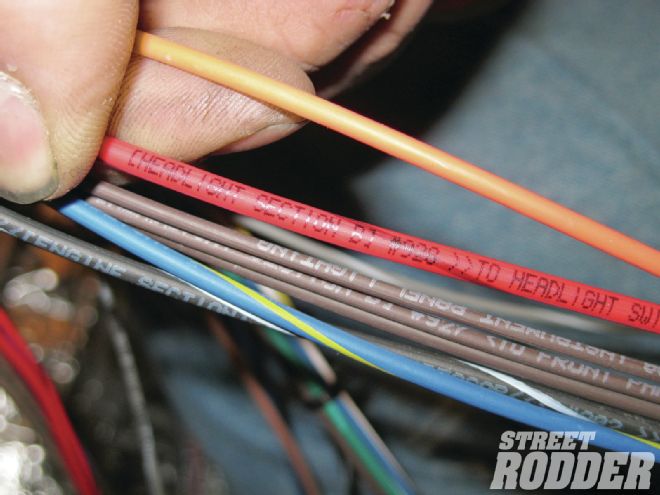

To make installation easy, the wires in our Painless harness are color coded and labeled.

To make installation easy, the wires in our Painless harness are color coded and labeled.

Circuit Breakers

Circuit breakers come in many different amperage capacities and are used in circuits the have high loads and voltage spikes. An electric fan circuit is a good example of a circuit that a circuit breaker should protect.

Wire Stranding

Did you know that in theory that current flows around the strands of wire? This means that the more strands of wire in a wire the more current that wire can carry. When doing wiring of a circuit, be sure the wire is high quality and has maximum strands.

Ignition Switches

Most aftermarket ignition switches are limited to about 60 amps of current carrying capacity. Always use caution when using a universal switch that it is not overloaded by it powering the electric fan circuit or the air conditioning circuit without a relay.

Where wires pass through any holes rubber grommets should be installed.

Where wires pass through any holes rubber grommets should be installed.

LED Flashers

LED flashers are required in many vehicles because of the installation of LED tail and front turn signal assemblies. LEDs do not pull enough current to trip the bi-metallic strip in a conventional flasher like the 1187-style bulbs. LED flashers have built-in resistance to solve the problem.

Good Grounds

Grounding of your ride is essential. Always connect the battery ground to the engine and tie the engine to the frame as well as the body with heavy ground straps or cable. If your dash gauges fluctuate when you turn on the lights, there is a grounding problem.

Computers and Welding

Never weld on the chassis or other parts of your ride without disconnecting the battery and also the computer, if so equipped. Electrical surges from welding can cause internal circuitry failure in a computer and could cause gases from the battery to explode.

Wires should be kept out of harms way. A good way to do that is to run them inside the body whenever possible.

Wires should be kept out of harms way. A good way to do that is to run them inside the body whenever possible.

Alternator Output

When choosing an alternator for your ride, always ask what the output is at idle. We all idle around the fairgrounds and the output at idle is more important than the maximum output rating. Be sure to only purchase one that has a minimum of 70 amps at idle.

Harness Routing

When installing a chassis harness and a fuel-injection harness, never route them through the same firewall hole. The radio frequency noise from the chassis harness could cause the signals from the sensors to the computer to get distorted and cause rough engine operation.

Battery Charging

When recharging the battery in your ride with a battery charger, always hook up the positive lead first to the battery and the negative lead to a good ground on the engine or chassis. This will prevent a spark close to the battery, which could cause an explosion of the batter gases.

Always use quality switches and plugs for the wires rather than individual connectors.

Always use quality switches and plugs for the wires rather than individual connectors.

Test Light/Voltmeter

When testing circuits, a test light or voltmeter can be used to check circuits in the main chassis harness but only a voltmeter should be used when testing circuits in the fuel-injection system. This will prevent unexpected loads on sensitive circuitry in the computer.

Electric Fans

On average, an electric fan will require 1 amp per inch of overall diameter to operate at normal speed. For instance a 12-inch fan will require 12 amps to operate but also note that twice the amperage is required during initial start up. Be sure the circuit protection can handle the start-up load as well as the fan relay.

Open Loop/Closed Loop

These terms are common when referring to an electronic fuel-injection system. Open loop refers to the fuel/air ratio controlled by the computer at a pre-set amount. Closed loop refers to the oxygen sensor reading the oxygen in the exhaust and constantly adjusting the air/fuel ratio for maximum efficiency.

Hot/No Start Problems

GM large starters are well known to not activate when they get hot from driving. This is due to the solenoid plunger expanding due to the heat and sticking in its housing. A relay between the solenoid activation terminal and the battery source, to flow more current, will almost always remedy the problem.

Soldering vs. Crimping

As the old saying goes “soldering is great on TV sets”. Controversy is long standing on this subject. The general rule of thumb is that if you are proficient in soldering and the wires being soldered will never move, solder them. In automobiles, wires are mostly moving and vibrating, which can cause a solder joint to break the wire next to the joint. Crimping is preferred.

Solid-State Devices

The term solid-state means that an electrical device has no moving parts other than electrons. Some of the common solid-state devices found in trucks are:

Diodes: These are one-way electrical valves; current can flow one way but not the other. Diodes are found in a number of places, most notably in alternators; they help transform alternating current to direct current.

Light-Emitting Diodes: Becoming more common all the time, LEDs have a small lens built in. The flow of electrons generates energy released in the form of light. Unlike a conventional bulb, no heat is created.

Transistors: These are solid-state switches used in applications like electronic ignitions to turn a circuit on and off, or in a stereo to strengthen a radio signal.

Resistors: Used to limit current flow, resistors can have a fixed value or they can be adjustable (also called a potentiometer).

Capacitors: A capacitor can store an electric charge. The condenser in a point-style ignition is actually a capacitor. Some electronic ignition systems use a capacitor to store an electrical charge that is released all at once.

Choosing an alternator

By Powermaster Performance

Alternators are usually described by their output—65 or 100 amp, or whatever. When replacing the alternator on the family car, this is probably the only information that is necessary. All that’s needed is an alternator that matches the original. But when building a street rod from the ground up a deeper understanding of the power curve of an alternator is required.

When selecting an alternator it’s better to have more output than needed as opposed to not enough.

When selecting an alternator it’s better to have more output than needed as opposed to not enough.

When selecting an alternator first you must know how many amps the electrical system consumes. This, of course, varies from car to car and can be figured two different ways. One way is to add the total amp requirements of all components together. Generally all electrical items will have their supply demands included with the instructions. Another way is to use an inductive ammeter with a “peak hold” function clamped around the battery cable while the car is running. While the latter method would be more accurate since it would be testing the electrical system as a whole, in real world conditions it’s not always the most practical. The point is that when everything is turned on at the same time, the amperage demands on the electrical system can be surprisingly high, so select an alternator accordingly.

How Big is Big Enough?

An alternator’s output is dependent on speed, but this can be deceiving because this output is not linear. Instead, it follows a curve and at idle small changes in the alternator’s speed can make a big difference in its output capacity. An 80-amp alternator is capable of producing 80-amp maximum. It does not produce power all the time but rather only when it is needed and only in the amount needed. Therefore if a street rod uses 52 amps continuously a 60-amp alternator could be used. However, an 80-amp alternator would work better. Why? Because the 80-amp alternator is working at 65 percent of its capacity whereas the 60-amp is working at 87 percent of its capacity. This percentage, or duty cycle, affects the voltage that the alternator is able to maintain. The 60-amp unit will typically produce the 52 amps at a lower voltage than the 80-amp unit in the same situation. Therefore it is good to get the alternator with the highest amp rating available for a particular mounting situation.

Choosing a Battery

There’s nothing worse than hopping into your hot rod, hitting the starter, and hearing a click rather than a roar. We generally advocate installing the largest battery that will fit.

Batteries are rated in a variety of ways:

- Ampere-hours indicate how long a battery will deliver electricity before it goes dead. This rating can be misleading as testing is not always done at the same rate of discharge.

- Cranking amperes is the amount of current a battery can provide at 32 degrees F.

- Cold cranking amperes is the amount of current a battery can provide at 0 degrees F.

- Hot cranking amperes is the amount of current a battery can provide at 80 degrees F.

- Reserve capacity minutes is a battery’s ability to deliver 25 amps before it drops below 10 V.

AGM Batteries

Looking a little like a six-pack encased in plastic, Optima AGM (Absorbent Glass Mat) batteries are widely used in street rods. AGM refers to the separators that hold electrolyte like a sponge. These maintenance-free batteries are completely sealed, preventing corrosion and acid spills, are more than 15 times more vibration resistant, and can be mounted in almost any position (upside down is not recommended).

Optima offers a variety of AGM batteries that are perfect for street rods. Yellow tops indicate a deep cycle design, red is found on starting batteries (there are also blue tops for marine applications).

Optima offers a variety of AGM batteries that are perfect for street rods. Yellow tops indicate a deep cycle design, red is found on starting batteries (there are also blue tops for marine applications).

Optima RedTop batteries are designed for starting applications that require high amperage for a very short time. The discharge cycle is shallow and the alternator takes over after the battery starts the car.

Optima YellowTop batteries are dual purpose, deep cycle designs for starting your vehicle and to support a load of electronic accessories, including car alarms, audio systems, and lighting. These batteries are also ideal in vehicles that don’t have an alternator or have electrical demands that temporarily exceed the alternator’s output. It ensures that those high electrical demands are satisfied until you’re able to recharge.