Of all that is bad in this world, rust might be the number one enemy of all classic car collectors and enthusiasts. And if you’re thinking about selling your vintage ride, the mere sight of it will deter any right-minded potential buyer.

Automobile rust is caused from moisture being trapped in various areas of sheetmetal for a period of time. Obviously, the longer the moisture has been present, the more likely the area has or will succumb to damage. It’s most notorious in places like quarter-panels or anywhere there might be a rubber seal that has been hardened and is no longer doing its job of sealing or keeping moisture out. One of the trouble spots in this situation (depending on the model of car) is under the rear window trim. Over time rubber seals can harden or crack. From that point moisture gets under the rubber, sets camp, and begins breeding corrosion and rust.

Floorpans are another common place for rust. As moisture gets trapped under the carpet it never really gets a chance to totally evaporate. Over a long period of time that moisture eventually becomes a catalyst for rust.

There are occasions when rust appears in some unlikely places as in the case of this 1969 Camaro. Moisture somehow got trapped between the driprail and the A-pillar on the driver side and caused some nasty corrosion. The issue here is that it was unknown exactly how far the rust traveled down, or up, the A-pillar. The only way to find out is to dig in and investigate the situation.

It’s best to tackle the problem once it’s first discovered. It will only worsen as time goes on.

Adam Ramsey, shop foreman and lead fabricator at Barry’s Speed Shop in Corona, California, took us through the process of removing rust, then repairing the damaged area from this somewhat unusual location.

Follow along as we take you through the steps of rust removal and repair.

01. Here is a good look at what got our attention. It appears the rust took up residency in a relatively small area on the driprail. Barry’s Speed Shop’s shop foreman, Adam Ramsey, will have to remove some paint in order to fully evaluate the situation.

02. With a metal pick, Ramsey dug around to get a better look at the corrosion and how extensive the damage was.

03. You can see here he was able to dig out most of the rusted metal. He marked a few inches beyond the corroded area where he’ll then cut out the damage and replace it with fresh sheetmetal.

04. Even though the car will eventually be getting fresh paint, this repair will be spitting sparks and debris in all directions. So it’s a good idea to shield the car from errant shrapnel.

05. With a cutting wheel, Adam hits his marks and begins removing the damaged piece of sheetmetal.

06. Here’s a good look at the piece that will be removed. Ramsey was careful not to cut all the way through the A-pillar – just the damaged portion of the driprail. Don’t throw it away just yet, we’ll need it a bit later.

07. Again, being careful not to dig too deep, Ramsey finishes off the removal process with an air saw.

08.With the rusted piece removed, you can get an idea of exactly what’s being replaced.

09. With a 60-grit sanding disc, Ramsey cleans up around the area that will house the new piece. It’s important to have a clean surface when welding in the new sheetmetal as welds will not adhere well to a dirty or painted surface.

10. Here is where keeping that old piece comes in handy. Ramsey used it to measure and mock up a new piece.

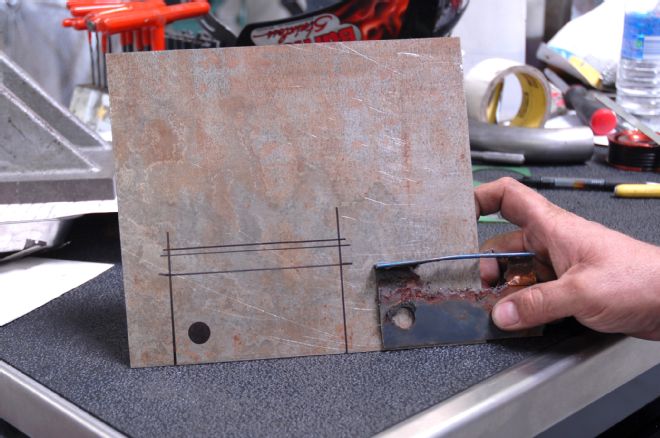

11. Using the measurements from the damaged piece, Ramsey marked it up on 19-gauge sheetmetal.

12. A stomp shear helps to make a perfectly straight cut on the new piece.

13. A sheetmetal brake was used to get the correct bend exactly where needed.

14. Here’s a good look at the old piece next to the new one.

15. Ramsey checked the fitment of the newly created piece.

16. A good coat of U-Pol Acid Etch Primer on the underside will help with future protection.

17. Same goes for the surface of the A-pillar.

18. Before he welds the new piece in place, Ramsey hits it with a healthy amount of Autobody Sealant. This will also help keep corrosion out in the long term.

19. Ramsey then utilized the existing trim screw hole to hold the new piece in place. This helps keep it tight before he TIG welds it in place.

20. Let the welding begin.

21. The donor piece looks like a perfect fit.

22. A body file was used to knock down the high spots of the weld.

23. A little metal is added along the edge to fill the contour of the driprail.

24. A nice bead on the outer area will give Ramsey more surface to work with as he shapes to the contour of the driprail.

25. A little more shaping and smoothing with the body file was necessary. At this point it’s difficult to tell where the new piece was welded in, which is the point of this repair.

26. Ramsey lightly gives pressure to the edge of a cutting wheel to get the high spots of the weld smoothed down. This is effective in keeping heat penetration to a minimum.

27. Now he hits the area with a 120-grit sanding disc in order to smooth and prep for primer and paint.

28. The new piece is all smoothed and ready for primer.

29. Here is the finished product. With the right tools and a bit of experience, this job can be done at most any home-based shop or garage.