When last we left our Project EJ25 build (May '14 issue), we assembled our bottom end using some key components, including Carillo Pro H-Beam connecting rods, JE Pistons, and a Cosworth high pressure/volume oil pump along with a pair of their head gaskets. Prior to mating the Port Flow-prepped cylinder heads, the entire rotating assembly was sent to Revco Precision located in Long Beach, CA, for a full balance and blueprint process. WPC Treatment also played an integral role in surface treating our crankshaft, King Engine bearings, pistons, and rods to create a harder, more durable surface with the added benefit of reducing surface friction.

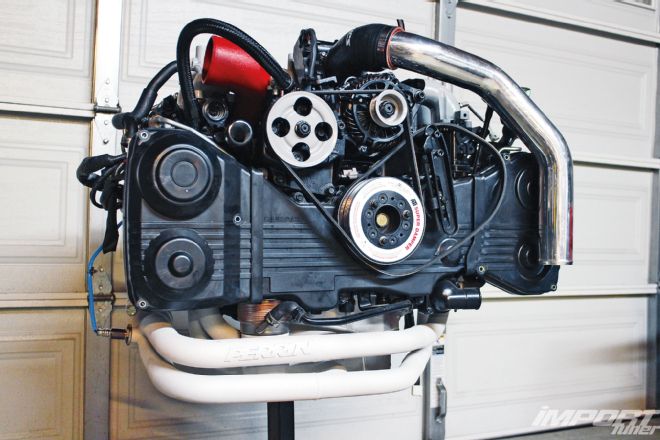

For our third and final installment, we pull the wraps off the stuff you've been most waiting for: the turbo kit system and reverse manifold setup. If you recall, a deadly combination of over boosting due to a dislodged wastegate line at the track caused a lean air/fuel condition that melted our Cosworth piston, which caused a nightmare of chain reactions that ended with a dramatic engine fire. We were able to salvage the cylinder heads, but the block was decidedly thrown in the garbage and replaced with brand-new case halves we purchased from South Coast Subaru located in Costa Mesa, CA.

| Project Subaru EJ25 - Part 3

| Project Subaru EJ25 - Part 3

CDF Racing Adjustable Cam Pulleys

The factory cam gears are designed using phenolic plastic and have been known to crack or break upon installation or removal. CDF Racing adjustable cam pulleys are a direct copy of the stock pulleys and have been used by professional race teams across the world including Vermont Sports Car Rally Team. These hard-anodized cam gears allow you to dial in your vehicle's aftermarket camshafts for maximum power by allowing your camshafts to open the valves to their limits. The CDF pieces are designed using stainless steel centers with Heli-Coil stainless threaded inserts and 12.9-grade bolts for superior strength and reliability. We used an AMS Performance's Subaru cam gear tool to remove and install all four cam gears. | Project Subaru EJ25 - Part 3

| Project Subaru EJ25 - Part 3

| Project Subaru EJ25 - Part 3

| Project Subaru EJ25 - Part 3

KS Tech Intake/ Throttle Body Spacer

When it comes to reversing your intake manifold, there's no easier way than using a set of intake manifold spacers. The KS Tech 9.5mm Phenolic spacers provide necessary alternator to throttle body clearance for any reverse intake manifold modification as well as insulating engine heat away from the manifold. | Project Subaru EJ25 - Part 3

| Project Subaru EJ25 - Part 3

The KS Tech 1/2-inch throttle body spacer enabled us to mount our drive-by-wire throttle body to the manifold without having to rotate the piece to clear the DBW motor assembly. We should also note that KS Tech offers OEM quality intake and throttle body gaskets both in OEM size and enlarged bore diameters.

| Project Subaru EJ25 - Part 3

| Project Subaru EJ25 - Part 3

| Project Subaru EJ25 - Part 3

| Project Subaru EJ25 - Part 3

T1 Race Development Fuel System

It's no secret that the '04-06 Subaru STI side-feed injector upgrades are limited in upgrade sizing (850cc unmodified) in comparison to top-feed units. When upgrading our fuel system, we revealed that not only was injector size an issue, but upgrading to a top-feed injector required changing our TGV's (tumble generator valve) setup as well.Killing two birds with one stone, we contacted T1 Race Development to purchase their T1 Side Feed Conversion Kit with optional fuel feed lines for our STI. The T1 fuel system was designed to retain the factory side-feed TGV's but replace the fuel rails with a top-feed fuel rail setup and spacers that allow the use of any Injector Dynamics high-impedance injector, ranging from ID725 to ID2000.

The CNC-milled 6061 aluminum top-feed injector rails are fed by lightweight black nylon performance hoses to a set of ID1000 injectors.

BorgWarner 7163 EFR Turbocharger

BorgWarner's 7163 EFR (Engineered For Racing) Series turbocharger came highly recommended by Geoff Racier of Full-Race and with good reason. There's an abundance of turbochargers available on the market today, ranging from small to big. When opting on purchasing this kit, our intentions were not looking for pure top end, but a good combination of response, spool, and flow enough cfm to outflow any factory turbo when attacking any future road courses. The 7163 turbo uses a forged-milled 71mm od compressor wheel with a 57mm inducer to support an impressive 60 lb/min max flow rate and a low inertia 63mm Gamma Ti turbine wheel. The BW 7163 uses a B1 frame turbo, the smallest-sized EFR compressor-housing BW offers, which allows our STI to maintain the factory location turbo configuration without having to switch to a rotated setup. Initial testing by Full-Race using their bolt-on kit with the 7163 delivered a quick spool that was on par with the factory turbo and superior response till redline that was sufficient for the 400-550hp range.Highlights of the turbo include Gamma Ti turbine wheels, dual-row ceramic ball bearings and cast stainless steel turbine housings, not to mention the boost control solenoid valve is also integrated to the compressor housing. An optional speed sensor kit is also available if you plan to push your turbo to the limit. We had our exhaust housing treated with a high-temp ceramic coating that's able to withstand over 2,000 degrees F.

| Project Subaru EJ25 - Part 3

| Project Subaru EJ25 - Part 3

| Project Subaru EJ25 - Part 3

| Project Subaru EJ25 - Part 3

Full-Race Turbo Kit

The Full-Race Stock Location EFR (internal wastegate) Turbo Kit come complete with an EFR compatible up-pipe and downpipe (optional high-flow catalytic) with V-band and installation hardware to locate any B1 frame BorgWarner EFR turbo within the factory location. The BW's turbo design consists of a T25 inlet flange and a 3-inch V-band discharge. The Full-Race up-pipe and downpipe are what allows it to fit in stock location. If you're looking for ultimate in stealth factor using your existing top-mount intercooler, while keeping those prying law enforcement eyes at bay, this is it. | Project Subaru EJ25 - Part 3

| Project Subaru EJ25 - Part 3

Perrin Equal Length Header

The benefits of using an equal-length header typically outweigh an unequal length header setup in both performance and response category. Other than the unique Subaru Boxer rumble associated with using an unequal header, we decided to upgrade to a Perrin equal-length unit we acquired through Turn 14 Distribution located in Montgomeryville, PA. The equal-length design offers smooth exhaust pulse transition, which delivers a quicker turbo spool and more horsepower and torque throughout the entire powerband. | Project Subaru EJ25 - Part 3

| Project Subaru EJ25 - Part 3

| Project Subaru EJ25 - Part 3

| Project Subaru EJ25 - Part 3

Swain Tech Coating

White Lightning Coating is the most popular coating that Swain Tech has to offer. The ceramic coating is more durable and heat resistant compared to any cosmetic brush-on paint that's typically known to flake or peel off within days or even hours of driving your car. The rough-textured coating is applied by Swain Tech at .015-inch thickness compared to their competitors' .002-inch application and is recorded to reduce radiant heat by up to 35 to 55 percent. With a melting point of 3,000 degrees F, White Lightning is ideal for Subarus that suffer from excessive heat emitted from a combination of the headers, downpipe, and up-pipe. We sent all three of our parts to Swain Tech to be coated. Not only does it protect from radiant heat but it also serves to insulate the exhaust system and keep the hot exhaust gases from cooling down-a process referred to as "scavenging effect," which creates or maintains horsepower. | Project Subaru EJ25 - Part 3

| Project Subaru EJ25 - Part 3

| Project Subaru EJ25 - Part 3

| Project Subaru EJ25 - Part 3

AMR Turbo Inlet

Cast in one-piece solid aluminum, the AMR Turbo Inlet is a must-have upgrade for anyone looking to push more horsepower out of a stock location turbo setup. The cast piece is engineered with all the necessary factory port locations for a simple plug-and-play setup, but the most important feature is the two offset silicone coupler hoses for OEM and upgraded turbos that allow you to properly align the larger-than-factory diameter inlet. | Project Subaru EJ25 - Part 3

| Project Subaru EJ25 - Part 3

Spec Clutch

The Spec Stage 2 Plus Clutch Kit features a multi-friction disc in a full-faced configuration with carbon semi-metallic on one side and Kevlar on the other. The Spec Stage 2 Plus clutch offers good daily driveability and very good wear characteristics but provides 15-20 percent higher torque capacity than Stage 2. The hub is double sprung with spring cover relieves for flexibility and heat-treated components for strength and durability, making it ideal for street, drag, autocross, road racing, and drifting. | Project Subaru EJ25 - Part 3

| Project Subaru EJ25 - Part 3

ATI Super Damper

There's been a great deal of debate whether the Subaru needs a damped crank pulley due to the crankshafts short stature. We decided against using a lightweight and unbalanced pulley for the main reasons of harmonic and torsional crankshaft vibrations at higher rpm. The ATI Performance damper helps protect against engine harmonics and features a dual four-groove serpentine beltdrive on the outer shell to utilize the factory serpentine belt setup. All ATI Super Dampers exceed SFI 18.1 Safety Certification and are approved for competition use. | Project Subaru EJ25 - Part 3

| Project Subaru EJ25 - Part 3