| EVO IX AMS Turbo Upgrade

| EVO IX AMS Turbo Upgrade

Considering purchasing a turbo kit for your car can become a daunting task, let alone installing and tuning afterward. It can be done right, with rewarding results, but if you are too ambitious or inexperienced, purchasing that kit can result in a huge headache and most likely one or more blown engines.

|

EVO IX AMS Turbo Upgrade

|

EVO IX AMS Turbo Upgrade

So when a colleague of ours informed us that he was deciding to build his EVO IX to compete in the annual AWD Shootout and Super Lap Battle at Buttonwillow Raceway, we offered to lend a helping hand as well as document the buildup. Besides purchasing a quality turbo kit that offered long-term reliability, the most important factor was choosing the right turbo for his intended power level and the vehicle’s goals. The Voltex-clad EVO IX machine served as his daily driver as well as a weekend warrior at the track. After weeks of research and weighing all options, we decided to go with the AMS Performance V-band 750R turbo kit, along with purchasing a plethora of proper support modifications required for the engine to safely handle the increase in power.

The AMS EVO VII-IX Turbo Tuner kit is considered one of the most comprehensive kits sold on the market today. Keep in mind that boosted performance does not come cheap, and if the setup you are considering is surprisingly cheap, you should be wary of its quality. Unlike many turbo kits that require authorized dealers for installation, AMS designed this kit to be an easy install. The Precision Turbocharged kit comes with everything needed including stainless steel V-band clamps, heat shield wrap, five-ply silicone coupler hoses, water/oil lines, step-by-step instructions, and even zip ties to make the installation process as painless and simple as possible.

|

EVO IX AMS Turbo Upgrade

|

EVO IX AMS Turbo Upgrade

Prior to installing the new AMS turbo kit, our EVO IX was equipped with a 20G turbo (.77A/R ratio); Tomei Powered Expreme stainless exhaust manifold, turbine outlet, downpipe; 1,000cc injectors; XS Engineering FMIC; Cosworth CNC big bore head, 272/272 duration camshafts; Fujitsubo Super Ti exhaust and Open Source ECU tuning. At 24 psi of boost, the EVO produced 330 whp on Greddy USA’s “heartbreaker” Mustang dyno. Interestingly enough, the same setup was making 370 whp on another dyno. Regardless of our disappointing baseline horsepower number, we decided to stick with our 330 whp baseline to monitor how much horsepower the new setup would make, once we installed the AMS turbo kit and properly tuned the car.

Precision 58/58 Turbo (750R)

Rated HP: 750 hp capable (with supporting mods)

Turbo Spool: 3,600-4,400 rpm

Vehicle Applications: street/road course

Precision 62/66 Turbo (900X)

Rated HP: 900 hp capable (with supporting mods)

Turbo Spool: 4,200-4,700 rpm

Vehicle Applications: street/road course

Precision 67/66 Turbo (950R)

Rated HP: 950 hp capable (with supporting mods)

Turbo Spool: 5,000-5,500 rpm

Vehicle Applications: street/dragstrip

1. The AMS turbo kit provides you the key components essential to improving exhaust flow and maximizing the performance of your Precision Turbo V-band turbocharger, which includes a cast exhaust manifold, O2 housing, and downpipe.

|

EVO IX AMS Turbo Upgrade

|

EVO IX AMS Turbo Upgrade

2. At the heart of our turbo kit sits an AM-spec 750R turbocharger manufactured by Precision Turbo. The AMS 750R is the perfect choice for street, road race, and drag racing and the best all-around turbo on pump gas. This turbo uses an extremely durable ceramic dual ball bearing centersection with a modified billet compressor wheel. The AMS 750R turbo is a GT30R variant, capable of making 100 whp more than typical GT30R-framed turbos that have an older, less efficient design. The 750R has been proven to show minimal spool latency that’s about 100 to 200 rpm later than the GT30R, making this an ideal setup for both street- and track-driven vehicles. AMS claims to have seen as much as 500 whp on 93-octane pump gas and over 580 whp on race gas with this turbo, which happens to be the same turbo setup running on their time-attack EVO X.

|

EVO IX AMS Turbo Upgrade

|

EVO IX AMS Turbo Upgrade

3. Precision Turbo’s new ultrahigh-flow turbine wheel’s design increases horsepower over comparably sized standard designs, aids in improving initial turbo spool-up time and reduces turbo lag by having a lighter billet aluminum compressor wheel. Each compressor wheel is machined from a 2618-aluminum forging for added strength, higher efficiency, faster transient response, and maximum performance. The newest Precision Turbos use an “anti-surge” housing design, which machines holes into the compressor housing to help keep the air entering into the compressor inlet remain stable at higher speeds, limit the effects of surge, as well as provide additional airflow to make maximum horsepower at high boost pressure levels and across the entire rpm range.

|

EVO IX AMS Turbo Upgrade

|

EVO IX AMS Turbo Upgrade

4. Each V-band turbo kit is available with your choice of three different AMS-spec Precision Turbochargers (750R, 900X, and 950R) and incorporates the latest V-band exhaust housings with options for .64 or .82 A/R depending on your type of driving and target horsepower output.

|

EVO IX AMS Turbo Upgrade

|

EVO IX AMS Turbo Upgrade

5. Here’s a close-up of the AMS stainless steel cast 02 housing with recirculated wastegate dump. AMS offers an optional dump to atmosphere for additional cost. We decided to use the recirculated setup for our build . . . after all, this is our street car.

|

EVO IX AMS Turbo Upgrade

|

EVO IX AMS Turbo Upgrade

6. Although the AMS V-band kit comes with a Tial MV-R 44mm wastegate in your color of choice, we decided to swap the unit with a Turbosmart Hyper-Gate 45. The Hyper-Gate45 is a 45mm external wastegate that is compact in design, yet able to maintain proper boost control for our EVO. The Hyper-Gate45 features a unique locking collar design for reduced size and quicker spring changes. It also includes both inlet and outlet weld flanges and V-band clamps; the valve seat will directly bolt on to the new AMS turbo manifold.

|

EVO IX AMS Turbo Upgrade

|

EVO IX AMS Turbo Upgrade

7. The AMS exhaust manifold is a masterpiece of artwork in itself, but regardless of how badass it looks, it was designed not only for performance but longevity. Using CAD and casting designs, the manifold utilizes cast stainless steel construction, thus eliminating the possibility of cracking, a problem commonly associated with hand-fabricated tubular headers. By casting the main components of the manifold, AMS was able to maximize exhaust flow and efficiency through their enormous 2-inch runners to help spin the turbine wheel faster while promoting maximum power potential. The stainless steel, thick-walled header is 100 percent hand TIG-welded from the collector to the head flange as gas exits the turbo through a 3-inch cast O2 housing.

|

EVO IX AMS Turbo Upgrade

|

EVO IX AMS Turbo Upgrade

8. The cast head flange was designed extra thick for even sealing and big enough to accommodate large exhaust ports found on our AMS CNC-ported Cylinder Head and other ported heads on the market. AMS designed their turbo kits using V-band flanges to allow for easier fitment with no gaskets and easier maintenance when installing/removing parts on a regular basis. Every V-band is manufactured from heat-treated 431 stainless steel for superior strength, even under extreme temperatures.

|

EVO IX AMS Turbo Upgrade

|

EVO IX AMS Turbo Upgrade

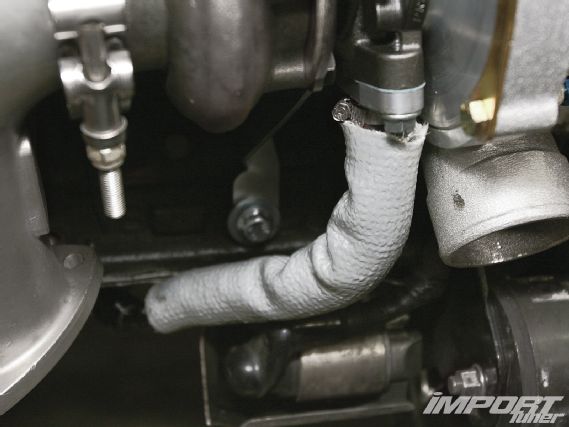

9. The only problem we encountered when installing the kit was an issue with the oil return line being too short. A quick run to the local Earl’s Performance shop to pick up a new line quickly resolved the problem.

|

EVO IX AMS Turbo Upgrade

|

EVO IX AMS Turbo Upgrade

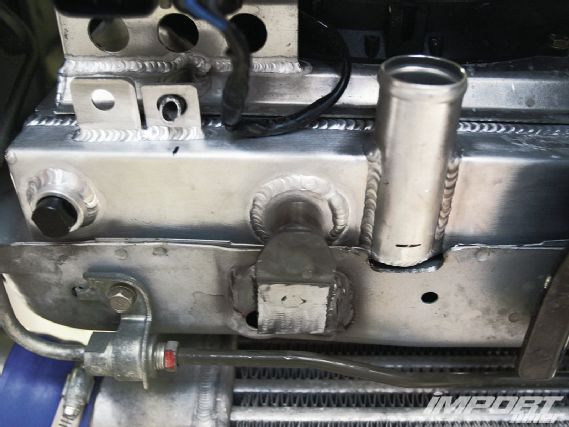

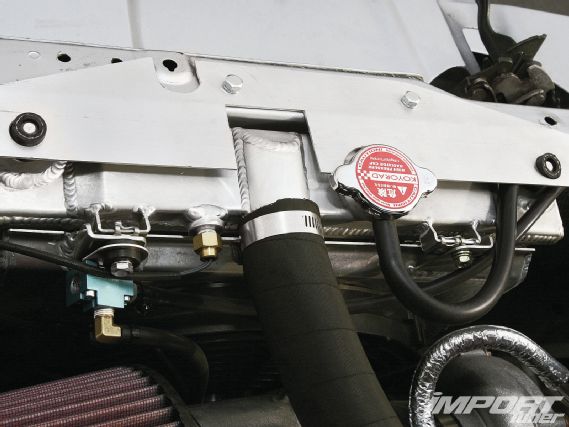

10. Koyo Half-Radiator

The Koyorad performance half-length radiator for the ’03-07 Mitsubishi Evolution was designed by Koyo engineers as an alternative cooling system for the growing number of Mitsubishi race vehicles with upgraded front-facing turbo systems. The double core, half-length radiator was designed for Sprint racing, small track, and gymkhana-type courses. The radiator uses an ultrahigh density 48mm “Hyper” performance core for superior cooling, while it’s reduced length allows for an off-center mounting position, which keeps radiant turbo/manifold heat away from its core.

|

EVO IX AMS Turbo Upgrade

|

EVO IX AMS Turbo Upgrade

11. A side-by-side comparison of the Koyo fullsize “R-Core” radiator alongside our new “Hyper core” unit shows the dramatic difference in size and an overall weight saving of 10 pounds. Although the question remains on whether the smaller-sized radiator would maintain proper cooling during street usage due to the smaller core, which is typically not suited for stop-and-go traffic, we remained optimistic with plans to closely monitor its performance once we hit the streets for testing along with hard runs at the track.

|

EVO IX AMS Turbo Upgrade

|

EVO IX AMS Turbo Upgrade

12. Although the AMS Performance V-band turbo kit was designed to clear the OEM fullsized radiator and AMS provided electric fan without issues, we opted to use the Koyo half-size unit along with a custom fan shroud we pulled from the previous radiator setup. AMS Performance reps state due to turbo-to-radiator clearance, a solid front motor mount or insert kit that AMS offers must be used to reduce engine movement when using a fullsized core.

|

EVO IX AMS Turbo Upgrade

|

EVO IX AMS Turbo Upgrade

13. A quick mockup of the Koyo radiator using the factory mounting points revealed the custom fan shroud was sitting less than an inch away from the turbine compressor housing. This was sure to be of concern if the engine experienced any torquing, which would cause rubbing.

|

EVO IX AMS Turbo Upgrade

|

EVO IX AMS Turbo Upgrade

14. To remedy the problem, Design Craft Fabrication of Westminster, CA, custom-fabricated a set of brackets to push the unit toward the driver headlight and finished things off by fabricating a custom-cooling shroud.

|

EVO IX AMS Turbo Upgrade

|

EVO IX AMS Turbo Upgrade

15. Koyorad integrates a 1/8-inch NPT female accessory fitting (supplied with a threaded plug) to accept temperature sensors typically supplied with most aftermarket temperature gauges.

|

EVO IX AMS Turbo Upgrade

|

EVO IX AMS Turbo Upgrade

16. We removed the factory air-conditioning core and compressor while installing our new turbo kit. Both were permanently removed from the car to save weight (40 pounds), while allowing increased airflow to our new radiator and to keep the engine bay clean.

|

EVO IX AMS Turbo Upgrade

|

EVO IX AMS Turbo Upgrade

17. Here’s a close-up of our turbo kit and half-core Koyo radiator installed. Looks pretty intimidating!

|

EVO IX AMS Turbo Upgrade

|

EVO IX AMS Turbo Upgrade

18. When horsepower demand increases, fuel consumption increases. To help feed our machine, we replaced our 255-lph fuel pump with an Aeromotive 340 Stealth fuel pump. This high-output, in-tank fuel pump is to work with OE fuel systems and is more than capable of handling our EVO’s horsepower level. At 40 psi, the Aeromotive 340 is rated to flow more than 340 lph, an increase of over 30 percent more flow than the factory fuel pump.

|

EVO IX AMS Turbo Upgrade

|

EVO IX AMS Turbo Upgrade

19. FIC 1,100cc Mitsubishi Injector Set

The Fuel Injector Clinic 1,100cc injector is the perfect solution for those looking for an injector that fills the gap between 900 and 1,000cc injector applications. The FIC 1,100s is a saturated/high-impedance ball and seat injector. Each injector flows 20 percent more fuel than 1,000cc Bosch EV14 injectors, but also provided a perfect cold start and idle on our daily driven EVO. Upon startup, we noticed the car idling much smoother and more responsive to throttle. The FIC 1,100cc injectors are both E85 and high-performance fuel compatible. When upgrading to a saturated/high-impedance injector type, the removal of the factory resistor pack is required.

|

EVO IX AMS Turbo Upgrade

|

EVO IX AMS Turbo Upgrade

20. AMS Brake Cooling Kit

The AMS Brake Cooling Kit was the perfect addition to our EVO as we were preparing to encounter some heavy braking during competition in the upcoming AWD Shootout. Although the kit is simple in design, the main purpose is to force airflow directly through the rotor vents to reduce the temperature of the rotors, brake pads, and calipers. Reducing the temperature of your brakes defends against brake fade and provides longer pad life.

|

EVO IX AMS Turbo Upgrade

|

EVO IX AMS Turbo Upgrade

21. This kit replaces the factory dust shields with 304 stainless steel caliper ducts and dust shields, which were designed specifically to force more air to exit through the rotor vents. The AMS Brake Cooling Kit was the perfect addition to our EVO as we were preparing to encounter some heavy braking during competition in the upcoming AWD Shootout. Although the kit is simple in design, the main purpose is to force airflow directly through the rotor vents to reduce the temperature of the rotors, brake pads, and calipers. Reducing the temperature of your brakes defends against brake fade and provides longer pad life.

|

EVO IX AMS Turbo Upgrade

|

EVO IX AMS Turbo Upgrade

22. The AMS Cooling kit includes 2-inch diameter high-temperature silicon tubing that is both lightweight and extremely flexible, and designed to withstand temps up to 500 degrees F. Also included is a pair of aluminum air inlet scoops that fit in just about any bumper or front grille opening. The kit is compatible on all Mitsubishi EVO VII, VIII, and IX with stock Brembo brakes.

|

EVO IX AMS Turbo Upgrade

|

EVO IX AMS Turbo Upgrade

23. AMS Performance Intake Pipe

With plans to use an HKS F-Con V Pro fuel management system that converts the factory MAF to speed density, we purchased an optional AMS Performance speed density intake pipe/K&N air filter kit to accommodate our new Precision Turbo.

|

EVO IX AMS Turbo Upgrade

|

EVO IX AMS Turbo Upgrade

24. Golden Eagle Thermal Shield Intake Manifold Gasket

The Golden Eagle Thermal Shield Gasket was another product we opted to use in preparation for the upcoming race event. The gasket uses a phenolic material that acts as a barrier to reduce heat soak between your intake manifold and your head. Stopping heat transfer results in a cooler inlet charge temperature, which translates to increased horsepower.

|

EVO IX AMS Turbo Upgrade

|

EVO IX AMS Turbo Upgrade

25. Golden Eagle Vacuum Manifold

Anyone who’s installed aftermarket boost controller lines and accessories knows how cluttered an engine bay can become with vacuum lines. To remedy this problem, we purchased a Golden Eagle Vacuum Manifold that’s specifically designed for turbocharged engines that require multiple vacuum sources. The distribution block is CNC machined from 6061 billet aluminum and designed with six usable 1/8 NPT (pipe thread) ports for items such as fuel pressure regulator, blow-off valve, MAP sensor, boost controller, boost gauge, and any other engine components that require a vacuum source.

|

EVO IX AMS Turbo Upgrade

|

EVO IX AMS Turbo Upgrade

26. We replaced the factory spark plugs with a set of HKS M-Series Super Fire Racing spark plugs. The HKS M40iL plugs are high-performance iridium plugs designed to deliver proper spark over our factory plugs while being rated one-step colder in heat range.

|

EVO IX AMS Turbo Upgrade

|

EVO IX AMS Turbo Upgrade

27. AMS Performance Downpipe

The 3-inch stainless steel downpipe included in every kit is fully TIG-welded with 100 percent stainless components, including the flanges and the hangers. The downpipe is designed with a built-in flex pipe to minimize cracking the manifold or header, and comes with a welded 02 bung. The downpipe was designed to bolt up to the AMS 3-inch cat-back system and the AMS high-flow cat or AMS test pipe.

|

EVO IX AMS Turbo Upgrade

|

EVO IX AMS Turbo Upgrade

28. Turbosmart E-Boost Street Boost Controller

The E-Boost Street electronic boost controller and its easy-to-use setup and intuitive operation make it a popular unit among forced-induction car owners. The E-Boost Controller features an adjustable gate pressure feature, which minimizes wastegate creep and can improve turbo response. The E-Boost controllers allow the user to control three different aspects of the boost curve: the maximum boost pressure (set point), the spool-up rate of the turbocharger (gate pressure), and the reaction time of the controller (sensitivity). The boost correction factor feature eliminates boost drop off at high rpm and boost warning, which automatically flashes at a preset level when warning of over-boost shutdown or rev limit, allowing the unit to be used as a boost gauge, tachometer, or a shift light.

|

EVO IX AMS Turbo Upgrade

|

EVO IX AMS Turbo Upgrade

29. The E-Boost features 40-psi max boost operating pressure and two boost settings, easily selected via the “turn-and-push” button. An external switch can also be used to change between boost groups, which require you to simply wire-up a two-way toggle switch as shown in the photo.

|

EVO IX AMS Turbo Upgrade

|

EVO IX AMS Turbo Upgrade

30. HKS F-CON V Pro Engine Management

The HKS F-CON V Pro is a full-featured standalone engine management system that connects easily to the factory ECU as a “piggyback” fuel and timing controller. As modifications to a vehicle are made, the need for fuel and timing adjustments becomes critical for performance and safety. The V Pro offers up to four selectable trim maps for different fuel octane ratings for custom street and race tuning options and can accommodate inputs from both MAP sensors and airflow meters.

|

EVO IX AMS Turbo Upgrade

|

EVO IX AMS Turbo Upgrade

31. The HKS AFK is an electronic monitoring device that displays two of the most vital engine conditions: engine knocks and air/fuel ratio. Knock occurs when there is abnormal engine combustion, known as detonation, caused by a combination of improper A/F ratios and ignition spark. This can rob power, reduce engine longevity, and even lead to catastrophic failure. The A/F Knock Amp utilizes the factory knock sensor, allowing you to monitor, in real time, engine knock visually and audibly via headphones (not included). A warning function can be set for both engine knock and air/fuel ratio where an audible alert sounds if the preset warning is reached. The main advantage of using a standalone system like the V Pro with the AFK in comparison to a reflashed ECU is the ability to protect the engine in an event of overboosting, overheating water temp, or dangerously lean air/fuel ratios, which can be set by the tuner to pull back the vehicle’s ignition timing to protect the engine to see another day.

|

EVO IX AMS Turbo Upgrade

|

EVO IX AMS Turbo Upgrade

32. Before attempting to fire up the vehicle, we wired up the V Pro using a Kuroyama Tuning V Pro adapter harness and installed both HKS air temp and pressure sensors to the engine.

|

EVO IX AMS Turbo Upgrade

|

EVO IX AMS Turbo Upgrade

33. The only downfall of owning an HKS V Pro is that you need a tuner in the HKS Pro Dealer network, which requires you to locate a pro dealer in your area to tune it. Luckily for us, we knew of one particular fellow by the name of Jon Kuroyama of Kuroyama Tuning. Kuroyama has been building and tuning cars since before you and I were conceived . . . Well, maybe that’s pushing it a bit too far, but as a former head engineer at HKS USA, he’s plenty knowledgeable with installing and tuning both the HKS V Pro and A/F knock amp. “We’ve all seen vehicle owners who demand 500 to 600hp tunes on pump gas. Sure, it’s been done before, but how safe is that tune? For a street car it’s about possessing a usable power curve.” Kuroyama says that our EVO tune was more on the conservative side while boost levels were kept to a minimum. “We’re not trying to break any dyno records on this EVO, I kept the tune within reasonable levels so it will last for more than two days of hard driving on the track.”

|

EVO IX AMS Turbo Upgrade

|

EVO IX AMS Turbo Upgrade

34. Here’s a final shot of our engine as we heat shielded both charge pipes and the intake pipe while making final preparations before we began our long drive to Buttonwillow Raceway to compete in both the AWD Shootout and Super Lap Battle. The two-day event was a true testament on how well both the car and new turbo kit would handle the physical punishment expected on the track.

|

EVO IX AMS Turbo Upgrade

|

EVO IX AMS Turbo Upgrade

35. With our Turbosmart boost controller set to 19 psi, the EVO made 390 whp and 329 lb-ft of torque—a peak gain of 64 whp over our previous setup. We could have easily risen up the boost for additional gains but as we mentioned previously, reliability and longevity was the key to our build. As expected with our new setup, we lost some low to midrange horsepower, which is a typical scenario among larger-sized turbos as our powerband shifted to the right on the graph. Kuroyama says more tuning time at the dyno could help recover the bottom end loss. At 7,000 rpm the new turbo setup gained 77 hp and 55 lb-ft of torque. The AMS turbo kit showed no signs of losing horsepower even at redline. This was a good indication that our Precision Turbo 750R is capable of flowing well beyond what our 2.0L engine could muster.

|

EVO IX AMS Turbo Upgrade

|

EVO IX AMS Turbo Upgrade

36. With Mike Chang of Evasive Motorsports behind the wheel for both days of competition, he offered some constructive criticism on how the EVO felt with the new modifications. “The AMS kit is impressive in terms of power and driveability in comparison to the previous setup on the car. The turbo has a very linear boost curve throughout the powerband and has good boost response considering the larger-sized turbo.” He continues, “One issue I had was the lack of rpm while exiting the corner through ‘bus stop’ but that was more attributed with the EVO’s five-speed transmission, which wasn’t suited for this particular track.” Chang made the most of his driving experience in the AWD Shootout. His quickest time of the day—1:58.891—was over a second faster than the EVO using the old turbo setup and third fastest in competition with only the Nissan R35 and R34 a few tenths quicker. The EVO remained competitive the following day at SLB, dominating the Street class category—2 seconds separated his closest competitor.

|

EVO IX AMS Turbo Upgrade

|

EVO IX AMS Turbo Upgrade

Collector Style vs. Log Style Manifold

The main purposes of an exhaust manifold on a turbocharged engine is to act as an exhaust gas delivery device from the cylinder head to the turbine side of the turbo. The exhaust gases expelled from the engine’s combustion chamber is known as an exhaust pulse. The turbo uses the energy present in the exhaust pulse to produce boost, so the faster and more efficiently the manifold can deliver exhaust pulses from each cylinder to the turbo, the quicker the turbo will spool up and produce boost.

|

EVO IX AMS Turbo Upgrade

|

EVO IX AMS Turbo Upgrade

There are two basic styles used when designing an exhaust manifold: collector style and log style. The exhaust flow, pressure, and runner length are all very important in deciding the many characteristics that make up a turbocharged car.

The stock 2.0L 4G63 exhaust manifold is classified as a “log style” because of the way that each exhaust port in the cylinder head discharges its exhaust pulse through the length of the manifold. A log-style manifold design works much differently than a collector-style design and is known to exhibit multiple performance disadvantages.

If you look at an EVO log manifold it’s pretty simple to see how the exhaust gases would fight against each other almost trying to cancel each other out. There is a divider on stock manifolds that splits cylinders 1, 4 and 2, 3. This pattern is the same with many aftermarket/custom tubular manifolds for 4G63Ts, with the primaries 1, 4 merging into a secondary and the same with primary runners 2, 3. The only real advantage to a log is being compact in size to clear power steering, AC, or radiator and economical manufacturing in mass quantities.

A tubular/collector-type manifold is usually custom made for that particular user’s goal for the car. Tubular manifolds are very efficient when compared to a log manifold. A collector-style manifold keeps each cylinder’s exhaust pulse separate until they merge at a single point called a “collector”. The basic idea behind keeping each exhaust pulse separate to the collector is to control and minimize the turbulence created when the exhaust pulses merge.

|

EVO IX AMS Turbo Upgrade

|

EVO IX AMS Turbo Upgrade

A less turbulent exhaust path means less work the engine has to do to “expel” the exhaust gases from the combustion chamber, which results in more energy going to the creation of power. A properly designed collector-style exhaust can help an engine in its job of evacuating exhaust gases from the combustion chamber, minimizing the potential power energy that is normally lost in this process. This also means more of the exhaust gas is expelled on each exhaust stroke of the crankshaft, which is known as cylinder scavenging.

The runner length is arguably one of the most important factors with a collector-style manifold. First would be to make sure that the runners are as equal length as possible. The idea being that the exhaust pulses will be spaced out evenly and arriving at the turbine wheel on the turbo at there own time in the firing order. If they arrive sooner or later, they may interfere with the exhaust pulses from the next firing cylinder. Next, a longer-runner manifold will have better flow up top, while a shorter manifold can yield a faster spool, with also less transient lag.

Regardless of the type of manifold design you choose, never buy a generic manifold. You are asking for trouble. These are cheaply made, probably won’t support the weight of your turbo, and have a higher chance of cracking. Why take the risk of spending more money replacing that part later, instead of doing it right the first time?