Rollbars are cool. Not only do they look "racy," but they provide protection in the event of an accident. That’s why they’re the minimum required in competition for coupes and sedans capable of running the quarter-mile between 11.00–11.99 seconds and convertibles clocking 12.00–13.99.

Of course, stuffing a rollbar into the confines of a compact car can be a bit of a challenge—so when it came time to build in some extra protection for his ’88 Honda CRX, Kenny Fong, head honcho over at Darkside Motoring in Chatsworth, California, opted for a kit from noted race-car chassis-builder Art Morrison.

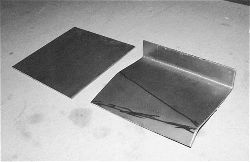

In recent years, an increasing number of import enthusiasts have been having Art Morrison Enterprises design custom rollbars (and cages, which are required for cars running 10.99 or quicker). As a result of this, the Fife, Washington–based firm has amassed a sizeable database for its computer-designed products, and the CRX was in its files. Then it was a matter of transferring the CAD data over to Morrison’s in-house tube-bending operation, and voila—the requisite 1.75 by .134-inch wall main hoop, side bars, and rear supports (along with 6 by 6 by .125-inch-thick steel plates) were packaged up as a kit.

The cost to have a rollbar installed professionally can typically be several times the purchase price of the rollbar kit itself, so knowing how to do it yourself is an appealing proposition for many performance enthusiasts. We took advantage of one of Morrison’s sojourns to SoCal, and he graciously spent a day showing how to install a rollbar the right way. Even though Art’s been doing this type of thing for 25 years and quickly marched through the project, he feels that most any competent home fabricator can do the install in one day. And the techniques shown here will apply to virtually any installation.

Before you start the installation, the interior should be stripped of as much as possible. This includes seats, door panels, carpeting, and the like. The headliner can stay put if it’s going to be kept. Some sound-deadening material will also need to be removed where the reinforcing plates will be welded to the floorboard. Follow along to see how easy is it to install a rollbar.

As a final reminder, NHRA rules require the rollbar to be made of 1.75 x .118-inch mild steel (an absolute). Tubing can come from mills with a tolerance of ±.006 inch and, as such, a standard .120-wall tube can really measure .114-inch in thickness—and not pass tech (inspectors use sonic testing equipment). Morrison makes their bars out of .134-inch wall material so there is never an issue about passing tech. If minimum weight is an absolute, rollbars (and cages) are available in .083-inch wall 4130 chrome-moly tubing. With a purchase price of $185, plus the effort to install it, a rollbar makes a very cost-effective investment in safety. And it just looks mean. Clearly, it’s a project that merits your consideration.

www.artmorrison.com