Before decoding synchromesh and dog gearboxes, it is critical to understand the beast. It’s all about engagement; how the gearsets are selected within the transmission is the difference between synchromesh and a dog box.

|

Gearbox Beatdown - Synchromesh vs. Dog Box

|

Gearbox Beatdown - Synchromesh vs. Dog Box

Synchromesh Transmissions

Most modern cars are fitted with a synchronized engagement gearbox from the factory to deliver smooth, reliable, and quiet operation, which is paramount for a daily driven vehicle. Synchromesh transmissions operate using a collar that applies force to a cone-shaped clutch attached to the gear. The collar allows the shaft speed of the gearset and the input shaft to be matched or “synched” to the output shaft prior to the collar locking into place and initiating a shift.

Synchromesh gear engagement is best at lower engine speeds and requires a bit more time compared to a dog box, to facilitate shifts. Limitations of synchromesh gearboxes in high-performance applications include slow upshifting at very high engine speeds—e.g. 9,000 rpm—and slow downshifting, as well as the need to fully use the clutch.

Dog Box Transmissions

Dog engagement is normally used in racing applications where fast, precise shifting is needed. Dog gear engagement is facilitated by numerous large teeth (dogs) that mate into matching openings machined into the opposite surface of the drive gear. Unlike the synchro engagement, there is no synchronizing mechanism to assist in equalizing speed. Ideal gear selection—e.g. minimal clashing and wear of the dog rings—is achieved by quick shifts; the motto here is “the quicker the better”, so bang away.

|

Gearbox Beatdown - Synchromesh vs. Dog Box

|

Gearbox Beatdown - Synchromesh vs. Dog Box

There is no depressing the clutch in the conventional sense like with the synchromesh transmission. A momentary break in engine load until the shift is achieved by a quick throttle blip or clutch depression. The driver will then experience the dog ring engaging with the next gear and the throttle can be reapplied. With practice this can be done in milliseconds. In fact, a driver can preload the stick shift in the direction of the next shift, and then when he either blips the throttle or clutch the shifter will quickly click in the desired gear.

With all else equal, dog-engagement gears are much stronger than synchro-engagement gears because without needing to make space for synchro rings, the gears themselves can be made thicker. The number of dogs (teeth) and the size of the openings determine the window of opportunity that the dogs have to engage during the shift event. Rings with a smaller number of teeth provide a more efficient, smoother shift quality. The downsides to this easier engagement are increased noise and abruptness on the shift.

Dog Gear Don’ts

The most destructive method of shifting dog gears is attempting to change gears in a “passenger car” or “synchromesh” manner. This involves slow shifting and use of the clutch—i.e. lifting off the throttle, depressing the clutch, moving the gear lever slowly, releasing the clutch, and applying the throttle—a scenario typically found in stop-and-go traffic.

|

Gearbox Beatdown - Synchromesh vs. Dog Box

|

Gearbox Beatdown - Synchromesh vs. Dog Box

Straight-Cut Myth

The belief that dog boxes inherently feature straight-cut gears is a long-standing misconception. In fact, either type of gearset can be fitted with straight cut—also known as spur–gears as well as conventional helical-cut gears. The cut of the drive gear is a separate characteristic of the gearbox and does not affect the engagement of the gears.

|

Gearbox Beatdown - Synchromesh vs. Dog Box

|

Gearbox Beatdown - Synchromesh vs. Dog Box

The Dog Pound

Dog engagement can be introduced to a stock gearbox by swapping gearsets. Aftermarket dog sets are usually made of higher-grade material and feature bigger, stronger teeth, and better profiles. Albins Gear, located in Australia, has moved to the forefront of the dog-box revolution, offering a wide range of dog-engagement gearsets as well as fortified synchro sets for Honda, Porsche, Nissan, Subaru, Mazda, VW, and Mitsubishi applications.

All Albins dogs feature a CAD “pent-roof” pentagon-shaped surface that deflects the dogs apart on a mis-shift, drastically extending the life of the gear. Albins dog gears are verified using a robotic CMM (coordinate measuring machine) to assure perfection with tolerances better than 0.015 mm on each and every part. Furthermore, Albins has been able to produce its own proprietary steel alloy with a consistency far superior to mass-produced, low-cost sets.

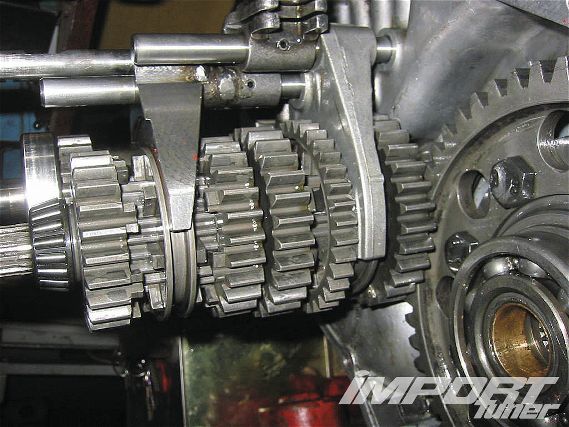

Synchromesh Versus Dog Box Gearset Comparison

Notice the thicker gears and teeth of the Albins unit (below) and the cuff that replaces Fifth gear (unneeded in the quarter-mile) and ties the two shafts together for added strength. The Albins gears and teeth are not only thicker, but they are also made from the company’s proprietary steel alloy for superior metallurgical strength.

|

Gearbox Beatdown - Synchromesh vs. Dog Box

|

Gearbox Beatdown - Synchromesh vs. Dog Box

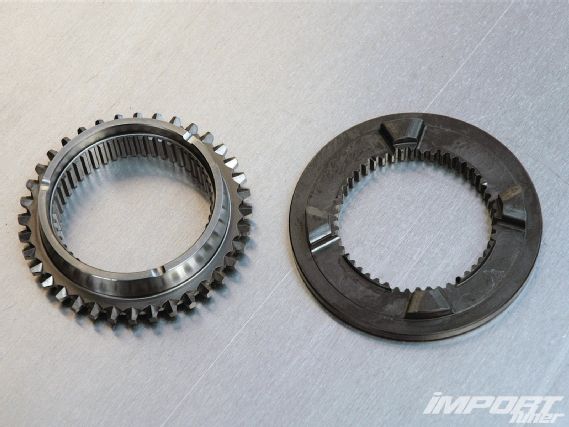

Cone and Dog Rings

Here is the big difference between synchro and dog boxes. The synchromesh ring (left) uses a cone that a brass clutch ring pushes against to equalize the speed between the gear and the input shaft to ease gear engagement. Once this happens, the small pointed teeth around the perimeter deflect off the engagement ring and allow the slider to engage the gear. The dogs have four large engagement teeth that drop into large windows in the slider, and can engage the gear even when spinning at a different speed than the input shaft.

|

Gearbox Beatdown - Synchromesh vs. Dog Box

|

Gearbox Beatdown - Synchromesh vs. Dog Box

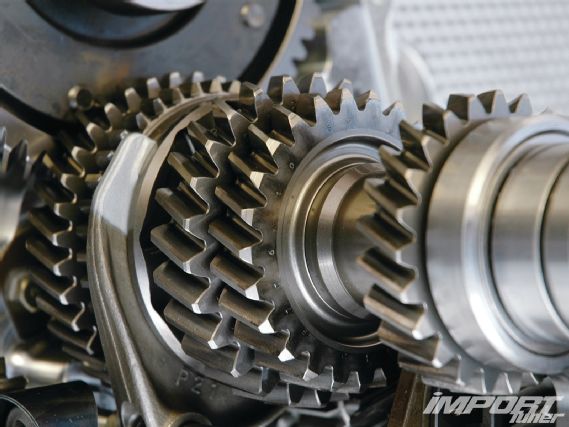

Rings and Gears

Here we see the rings on their appropriate gear. This is how they would be installed in the transmission.

|

Gearbox Beatdown - Synchromesh vs. Dog Box

|

Gearbox Beatdown - Synchromesh vs. Dog Box

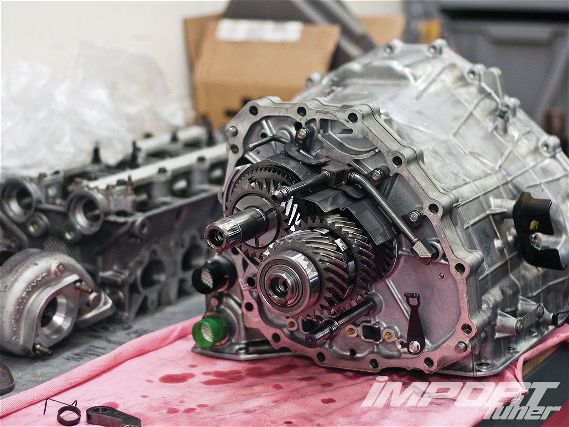

Gears In Case

Albins gearsets drop right into the stock transmission case, delivering nearly “sequential-fast” shifts without the sequential box price tag. Albins offers dog-engagement gearsets as well as fortified synchro sets for Honda, Porsche, Nissan, Subaru, Mazda, VW, and Mitsubishi applications.

|

Gearbox Beatdown - Synchromesh vs. Dog Box

|

Gearbox Beatdown - Synchromesh vs. Dog Box

SpeedFactory’s Outlaw-class Civic has been a rolling 1,100-whp gearset cruncher. It has competed up and down the West Coast and as far east as Englishtown. Its best efforts to date are 8.89 at 172 mph and 8.92 topping out at 179 mph, and Albins gearsets have contributed greatly to its reliability and consistency.

|

Gearbox Beatdown - Synchromesh vs. Dog Box

|

Gearbox Beatdown - Synchromesh vs. Dog Box

Gearset Savior

SpeedFactory Bulletproofs The B-Series Transmission

SpeedFactory Racing has developed an innovative modification for B-series hydraulic transmissions that eliminates inherent problems in the mechanism, avoiding the “speed shift blues” in street cars and race cars alike.

|

Gearbox Beatdown - Synchromesh vs. Dog Box

|

Gearbox Beatdown - Synchromesh vs. Dog Box

The Shift Change Holder Assembly (SCHA) is the problem child. Located inside the transmission case, the SCHA is the mechanism that actually moves the shift forks into position, engaging each gear as it’s selected via the stick shift. SpeedFactory modifies the SCHA in seven different areas to withstand the rigors of hard shifting in standard synchromesh or dog-engaged transmissions.

The stock shift change arm is the weakest link of the SCHA. The stock arm is made of low-quality stamped steel and over time is susceptible to stress cracks or bending when speed shifted. SpeedFactory replaces the stock arm with a heavy-duty, heat-treated arm CNC-machined from tool steel that will not bend or break.

The interlock piece is also a potential problem. SpeedFactory installs a brand-new OEM interlock, braces it, and performs some polishing/profile mods to endure the abuse of repeated power shifts, be it on the street or at the track in a drag racing application.

Finally, the shift select return spring has been upgraded with a much stronger unit. This gives the shifter a more positive feel, and returns the shifter to the center position with authority.

Beyond fortifying the transmission against breakage, the SpeedFactory SCHA also adds efficiency to the shifting process, especially the 2-3 shifts. Just push the shifter forward, and it will automatically drop into Third gear. It pulls the shifter to the center position with speed and precision to help eliminate the dreaded 1-2-1 or 2-3-2 gear mis-shifts.

The SpeedFactory improvements have been thrash tested on the company’s wicked 1,100-whp, 8.89-second Outlaw Civic with great success, ensuring more consistent shifts, lower e.t.’s, and saved transmissions for weekend warriors and hard-shifting, real-world street drivers alike.

The SpeedFactory modified SCHA (right) has a CNC’d tool steel shift change arm (with SF logo). Also, note the beefier return spring of the SpeedFactory piece at the far left.

|

Gearbox Beatdown - Synchromesh vs. Dog Box

|

Gearbox Beatdown - Synchromesh vs. Dog Box

SpeedFactory also welds the baseplate in several places for added strength and rigidity, and to prevent stress fractures. The custom SCHA will save transmissions by ensuring proper engagement in less than ideal shift scenarios.

|

Gearbox Beatdown - Synchromesh vs. Dog Box

|

Gearbox Beatdown - Synchromesh vs. Dog Box

SCHA Rear Buttress

Note the buttressing between the baseplate and the spring pad. This is just one of the seven different modifications SpeedFactory makes to the SCHA to ensure happy gear slamming.

|

Gearbox Beatdown - Synchromesh vs. Dog Box

|

Gearbox Beatdown - Synchromesh vs. Dog Box