| General Brake Maintenance - Tricks Of The Trade

| General Brake Maintenance - Tricks Of The Trade

Every once in a while your brakes need to be tended to. We made a step-by-step guide on how to do general brake maintenance for just the occasion. We addressed the issue of brakes, knowing how important it is to keep them at a safe and operating level to avoid any serious accidents or malfunctions/breakdowns. This guide will ensure that you will be able to figure out how to maintain your brakes without having to spend hundreds of dollars by bringing your vehicle into a repair shop.

Brake Maintenance Steps:

| General Brake Maintenance - Tricks Of The Trade

| General Brake Maintenance - Tricks Of The Trade

1. To begin the brake pad removal process, you will need a 14mm socket and a ratchet.

|

General Brake Maintenance - Tricks Of The Trade

|

General Brake Maintenance - Tricks Of The Trade

Following the format of “righty tighty, lefty loosey”, loosen the 14mm bolt holding the brake caliper

2. Flip the centersection of caliper open to expose the brake pads.

|

General Brake Maintenance - Tricks Of The Trade

|

General Brake Maintenance - Tricks Of The Trade

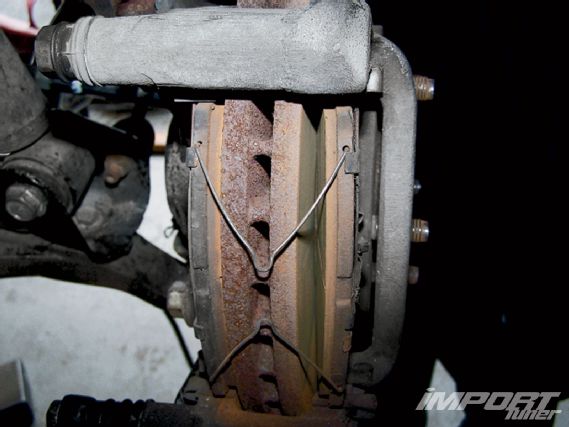

3. Proceed by removing the brake springs.

|

General Brake Maintenance - Tricks Of The Trade

|

General Brake Maintenance - Tricks Of The Trade

4. Remove both brake pads and inspect them for any cracks or worn material.

5. Remove brake pad shims from old pads.

|

General Brake Maintenance - Tricks Of The Trade

|

General Brake Maintenance - Tricks Of The Trade

6. Install shims onto the new pads.

7. Measure the brake rotor thickness using a micrometer to ensure they are within their proper specifications. Always refer to your factory service manual to ensure your brake rotors are within specifications. If they aren’t, new rotors are recommended.

|

General Brake Maintenance - Tricks Of The Trade

|

General Brake Maintenance - Tricks Of The Trade

8. Measure brake rotor runout with a dial indicator to ensure the rotor is reusable. When using the dial indicator, slowly turn the rotor and observe the needle on the indicator to get your runout reading. Once again, refer to your factory service manual to ensure your rotors are within specifications. If the rotors are not within specifications, replace them with a new set.

|

General Brake Maintenance - Tricks Of The Trade

|

General Brake Maintenance - Tricks Of The Trade

9. Use a C-clamp to compress the pistons back into the floating caliper for the new pads.10. Install the new brake pads, and then reinstall the brake pad springs.11. Flip the centersection of the caliper back up (closed) with new brake pads installed.12. Reinstall the 14mm bolt and you’re done!

|

General Brake Maintenance - Tricks Of The Trade

|

General Brake Maintenance - Tricks Of The Trade

10. Install the new brake pads, and then reinstall the brake pad springs.

|

General Brake Maintenance - Tricks Of The Trade

|

General Brake Maintenance - Tricks Of The Trade

11. Flip the centersection of the caliper back up (closed) with new brake pads installed.

12. Reinstall the 14mm bolt and you’re done!