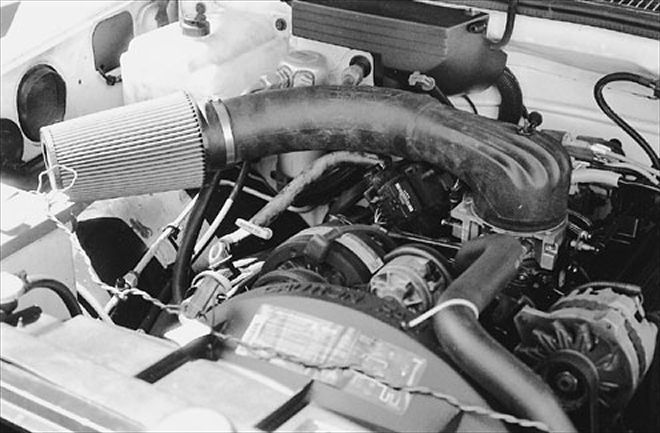

We begin where it all begins: the induction system. Your engine can’t pump out air that it doesn’t breathe in, and factory air cleaners, especially those from the mid-’70s and early ’80s, tend to put a gag on engine performance. On many trucks, correcting this situation by installing an open-element or higher-flow air cleaner assembly can unleash 5, 10, or even more horsepower.

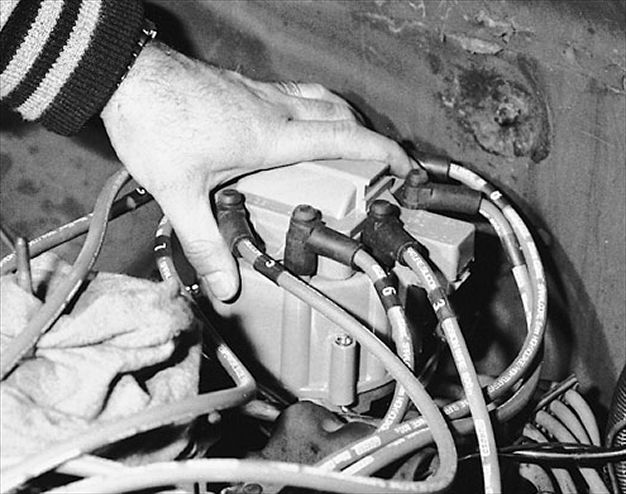

Another area of potential gain is the engine’s ignition system, which includes the distributor, cap, rotor, coil, plug wires, timing advance, and spark plug gaps. The general condition of your ignition system, including the cap and rotor and spark plug wiring, can have a huge impact on power and reliability. Upgrading to a good set of spiral-wound plug wires and a hotter aftermarket performance coil will ensure that your ignition system keeps pace as you upgrade other engine components, such as the exhaust, camshaft, and valvetrain. Once the components are in good order, you can delve deeper into the ignition system by experimenting with its timing. Ignition advance is the point at which the spark plug fires relative to the piston reaching the top of its travel on the compression stroke, and it’s measured in degrees of crankshaft rotation. For example, if initial timing is 14 degrees, the spark will fire 14 degrees before the piston reaches the top of its stroke. The reason that spark advance is important is because engines perform best when complete ignition of the air/fuel mixture and peak cylinder pressure occur just after the piston has reached TDC and begins to travel downward on the power stroke. To do this, especially at higher engine speeds where the spark fires up to 50 times per second, the air/fuel mixture must begin burning before this point so it has time to completely burn and produce maximum power.

Most engines incorporate three types of advance—initial, mechanical, and vacuum—which control the spark under different conditions of engine speed and load. Initial advance, which controls the spark at start-up and low rpm, is dialed in by rotating the distributor and using a timing light.Retiming the engine so that the spark fires earlier in the combustion cycle relative to top dead center gives the air/fuel mixture more time to burn in the combustion chamber before the piston begins its power stroke. Firing the spark too late, especially as engine rpm increases, wastes power because unburned fuel is expelled on the exhaust stroke. This is why most engines, especially those with low compression, respond well to advancing the timing respective to the factory setting. By advancing timing in small increments, say 2 degrees at a time, you can usually find a few horsepower.

Similarly, wider spark plug gaps, within the ability of the ignition to produce enough energy to fire across them, ignite the mixture more quickly and reliably. If you’ve got an inductive timing light and a spark plug gapper, you can experiment with different amounts of timing and plug gap until you find the combination that makes your engine happy.

Depending on the configuration of your truck, you can do several or even all of these things for about a C-note and pick up quite a bit of performance. Now that you can crawl, check out the next two parts of this series and learn how to run.